Endpoint force feedback system and method applied to grinding industry robot operation

An industrial robot and force feedback technology, applied in the field of force feedback system, can solve problems such as damage to the grinding head and quality problems, and achieve the effects of easy control, simple structure and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

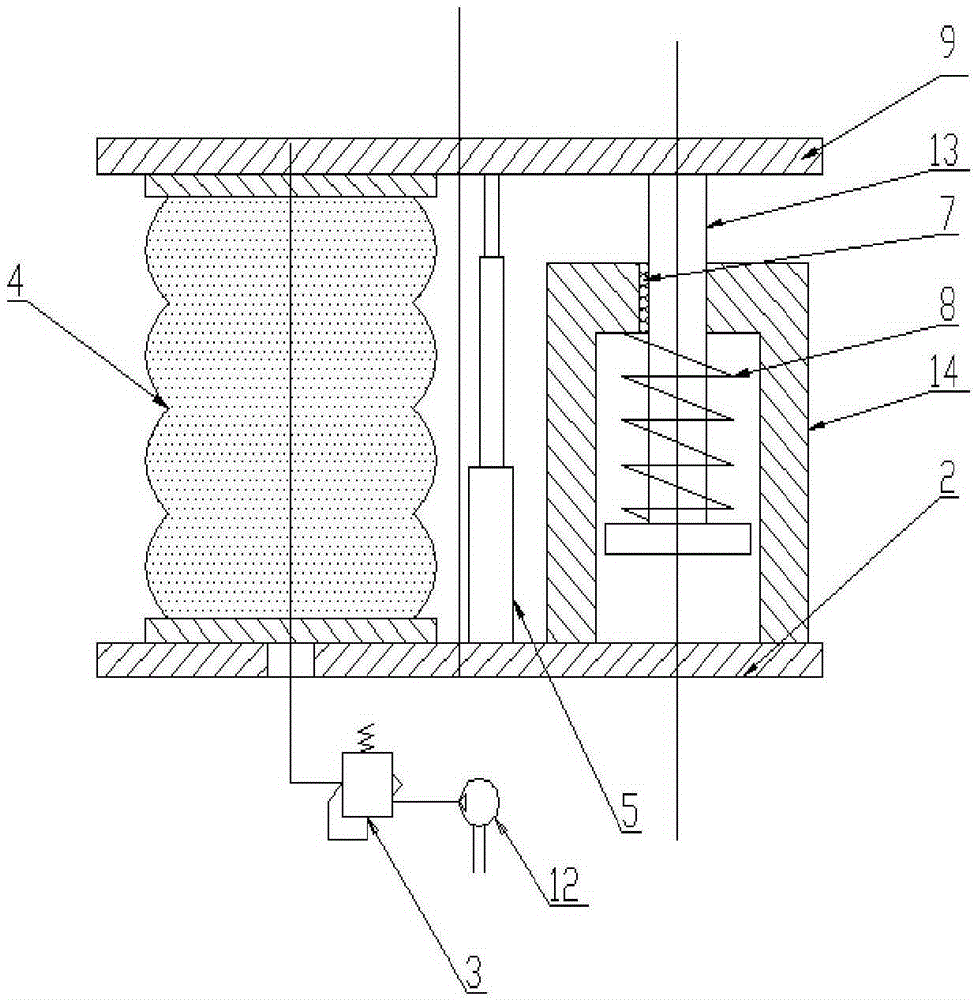

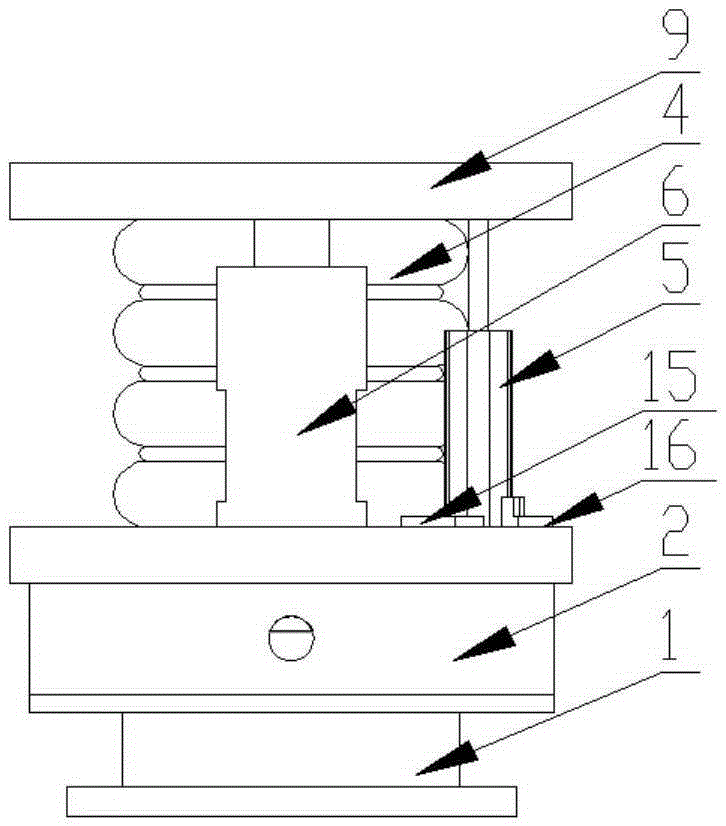

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

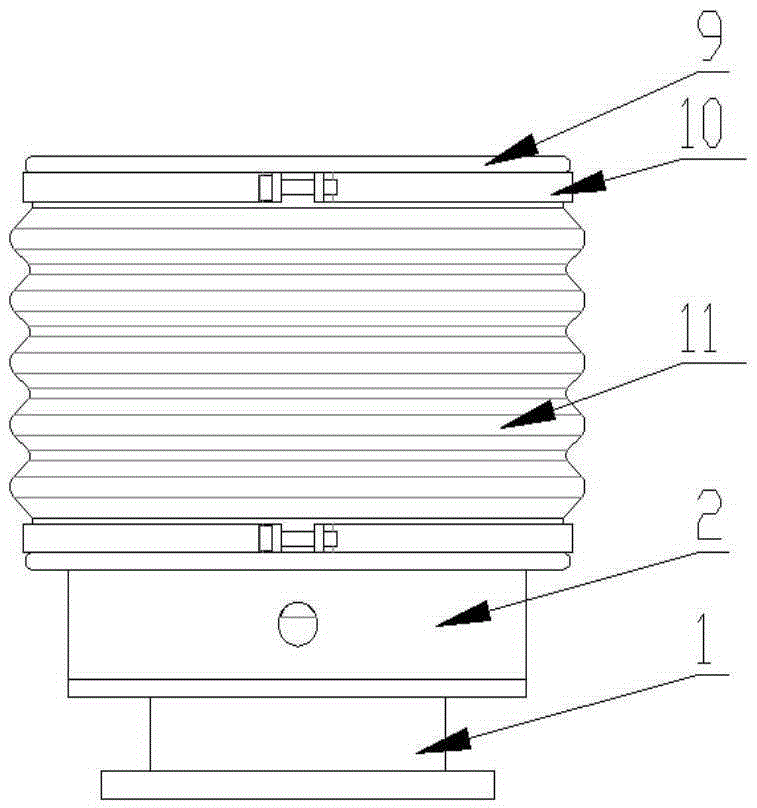

[0035] see figure 1 Referring to Fig. 3, the present invention provides a terminal force feedback system applied to grinding industrial robots, which is connected to the mechanical arm through a flange 1, including a lower base 2, an upper base 9, an air spring 4, a guide device 6, a displacement Sensor 5, compression spring 8, linear motion ball bearing 7, proportional valve 3, dust cover 11 and air compressor 12.

[0036] see Figure 2a and Figure 2b , the lower base 2 is connected to the flange 1, and is used to connect the terminal force feedback system applied to the grinding industrial robot operation with the mechanical arm of the robot; the upper base 9 is arranged opposite to the lower base 2, And form an accommodating space with the lower base 2 . Two ends of the dustproof cover 11 are respectively fixed on the upper base 9 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com