Combination control method for exit temperature of heating furnace

A technology of comprehensive control of outlet temperature, applied in temperature control without auxiliary power supply, controller with specific characteristics, adaptive control, etc., can solve problems such as device disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

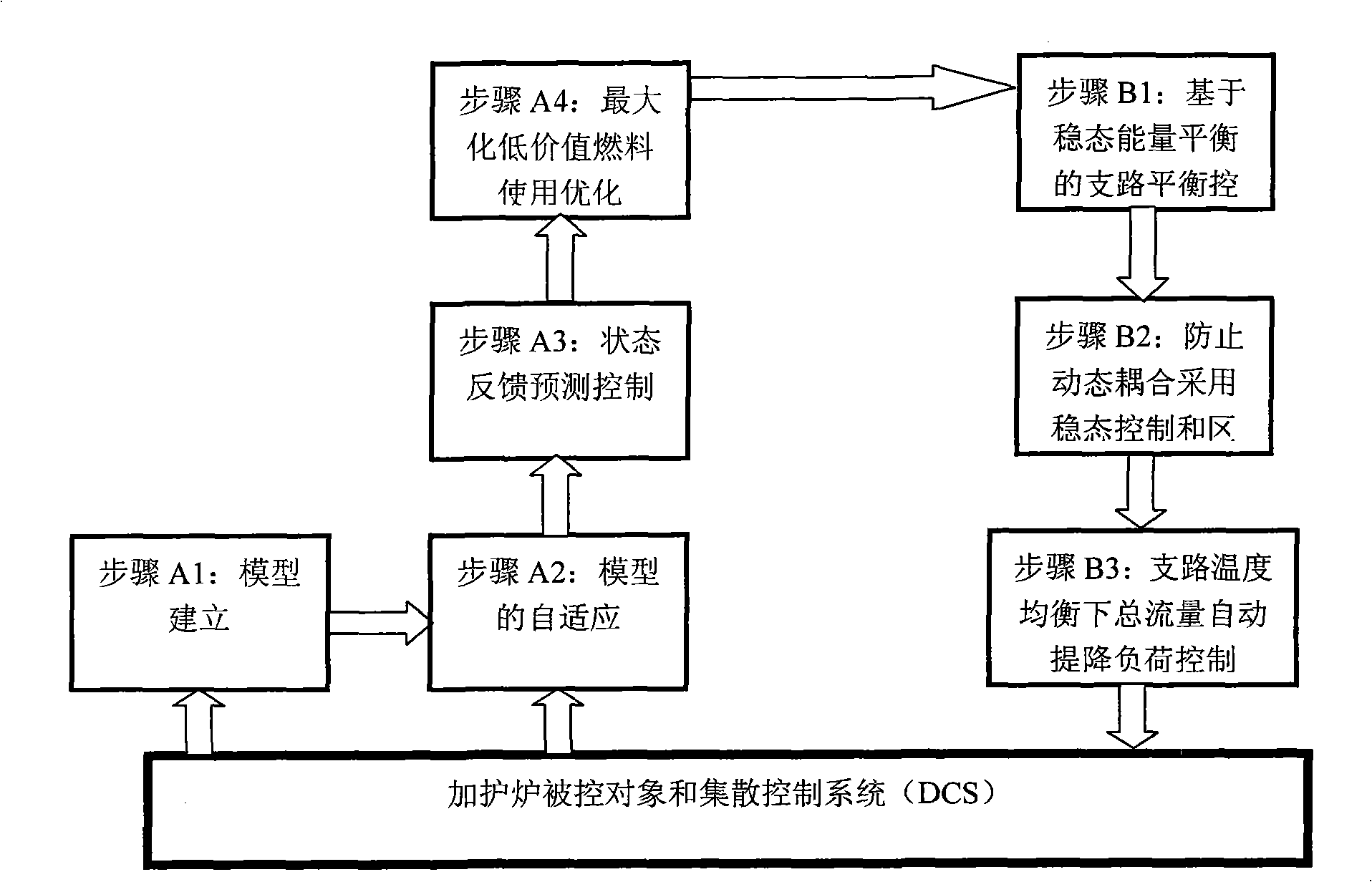

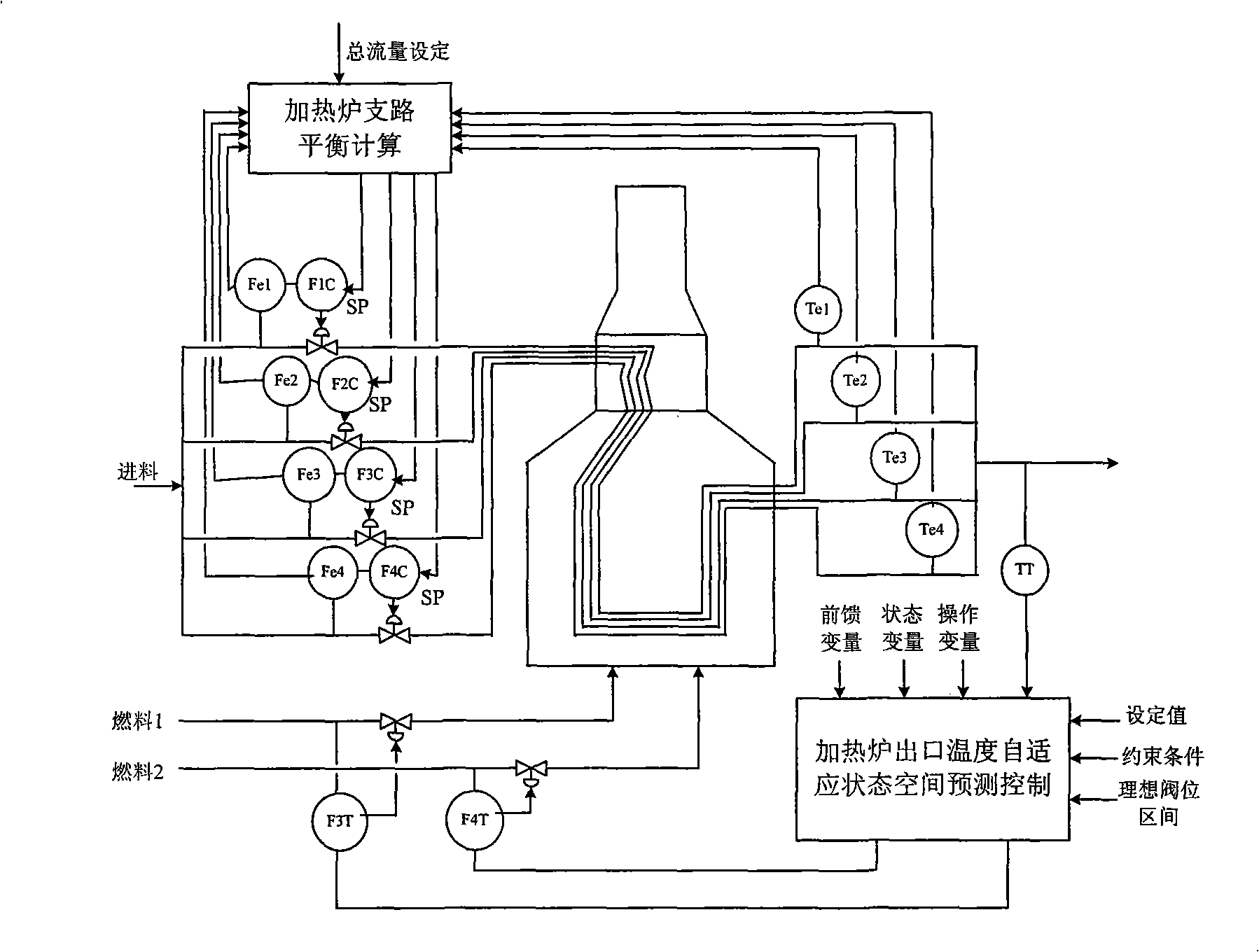

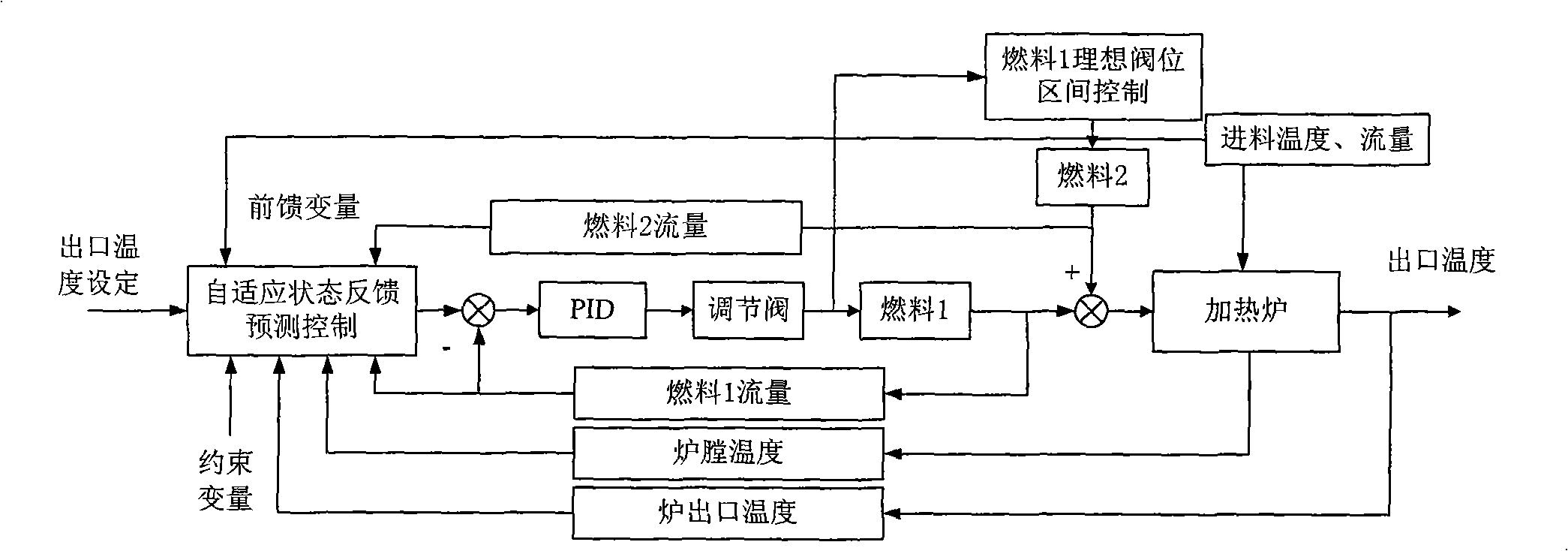

[0084] The method of the present invention contains the following two parts: the outlet temperature self-adaptive state feedback predictive control and branch balance control. The principle block diagram and overall structure diagram of the realization method are shown in the appended figure 1 And attached figure 2 .

[0085] The outlet temperature adaptive state feedback predictive control part includes the following steps:

[0086] Step A1: Establish a simplified mechanism model with the outlet temperature of the heating furnace, the furnace chamber temperature and the fuel flow (pressure) as state variables; this step is carried out in turn according to the following sub-steps:

[0087] Step A1.1: Assumption: (1) When the thermal efficiency of the heating furnace does not change much, the proportion of the effective heat absorbed by the fluid in the furnace tube to the total calorific value of combustion remains unchanged, and the heat loss of the flue gas is ignored in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com