Efficient, energy-saving and low-emission fur polychromatic dyeing all-in-one machine and fur dyeing method

A high-efficiency, energy-saving, multi-color dyeing technology, applied in liquid/gas/vapor textile processing, liquid/gas/vapor processing transmission, textile and paper making, etc., can solve the problem of long consumption, uneven dyeing, dyeing machine Energy waste and other issues, to achieve the effect of maintaining consistent temperature, improving dyeing effect, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

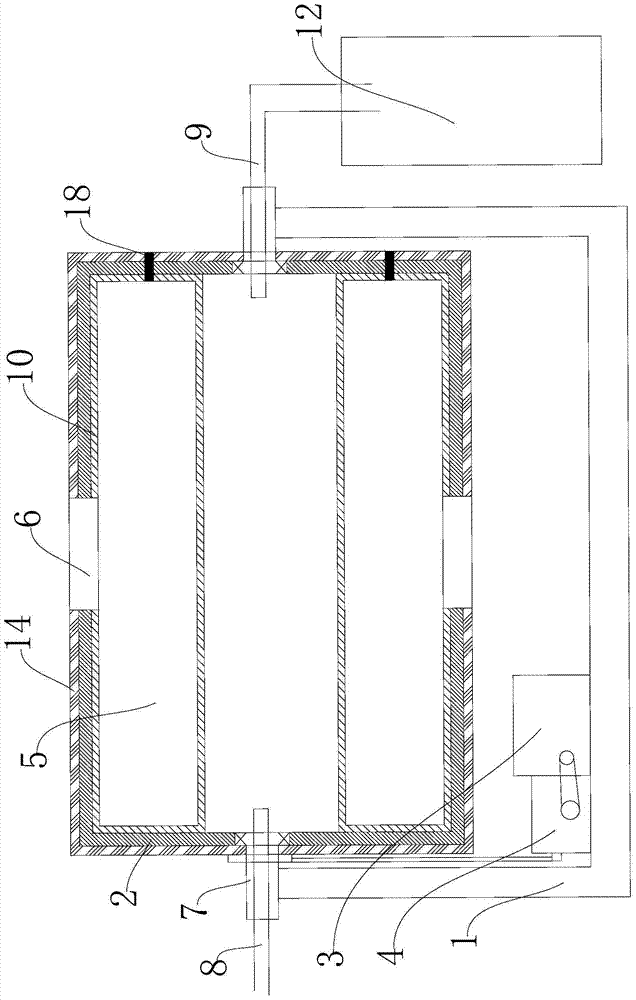

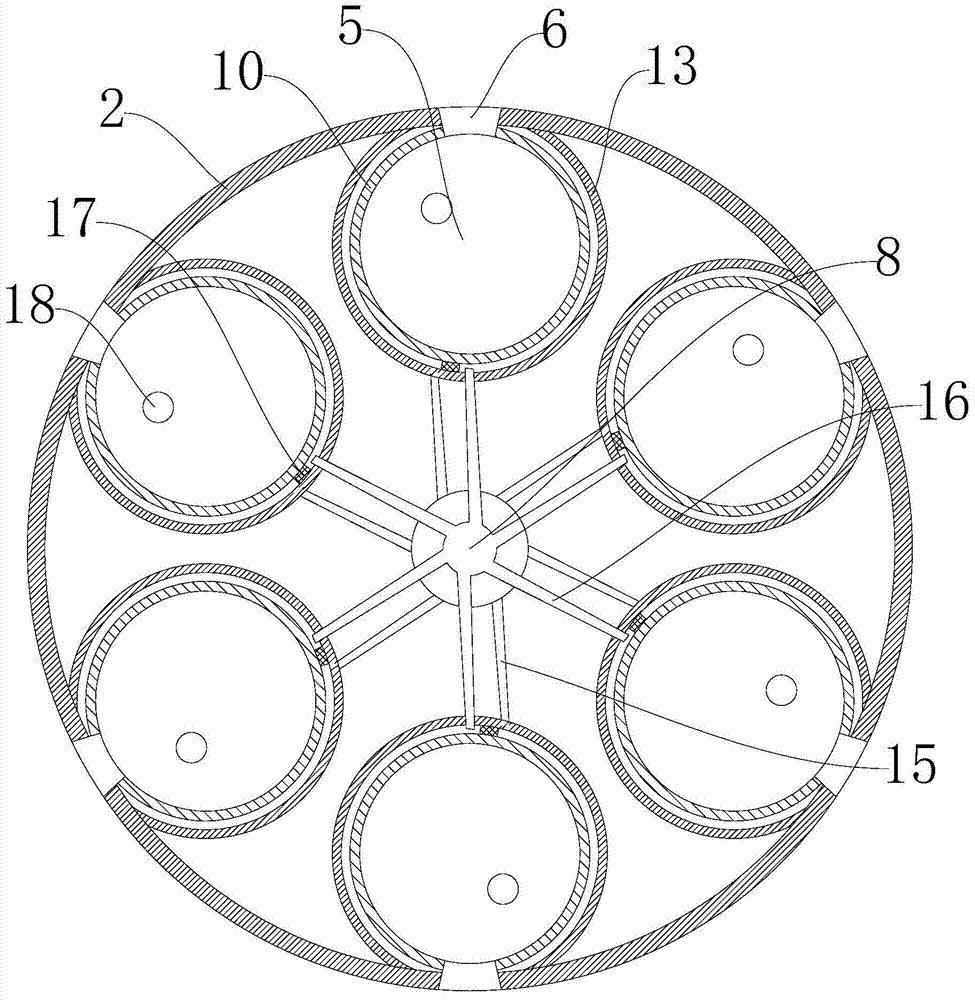

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the high-efficiency, energy-saving and low-emission fur multi-color dyeing machine described in this embodiment includes a frame 1, an outer cavity 2, a motor 3, a gearbox 4 and a dyeing cylinder 5, and the motor 3 drives the outer casing through the gearbox 4. The cavity 2 rotates, and the outer cavity 2 is connected to the frame 1 through the shafts 7 at both ends, and the shaft 7 is fixedly connected to the frame 1. A plurality of dyeing cylinders 5 are fixed inside the external cavity 2, and each dyeing cylinder The sides of 5 are provided with a pressure valve 18, the dyeing cylinder 5 is in contact with the inner wall of the outer cavity 2, and a feed door 6 is provided at the contact between the dyeing cylinder 5 and the inner wall of the outer cavity 2, and the dyeing cylinder 5 is in contact with the inner wall of the outer cavity 2. The annular wall 10 in the cylinder 5 is evenly spaced with a pl...

Embodiment 2

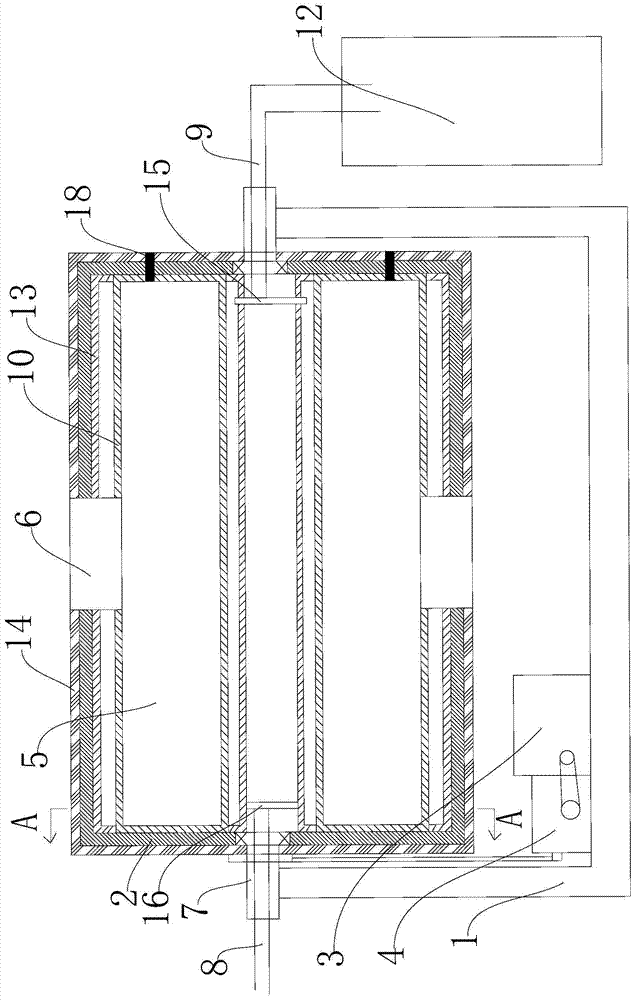

[0023] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, the high-efficiency, energy-saving and low-emission fur multi-color dyeing machine described in this embodiment includes a frame 1, an outer cavity 2, a motor 3, a gearbox 4 and a dyeing cylinder 5, and the motor 3 drives the outer casing through the gearbox 4. The cavity 2 rotates, and the outer cavity 2 is connected to the frame 1 through the shafts 7 at both ends, and the shaft 7 is fixedly connected to the frame 1. A plurality of dyeing cylinders 5 are fixed inside the external cavity 2, and each dyeing cylinder The sides of 5 are provided with a pressure valve 18, the dyeing cylinder 5 is in contact with the inner wall of the outer cavity 2, and a feed door 6 is provided at the contact between the dyeing cylinder 5 and the inner wall of the outer cavity 2, and the dyeing cylinder 5 is in contact with the inner wall of the outer cavity 2. The annular wall 10 in the cylinder 5 is evenly spaced with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com