One-way moisture permeable and heat preservation composite material and preparation method thereof

A composite material and moisture-permeable technology, applied in the textile field, can solve the problems of non-unidirectional moisture permeability and single function, and achieve the effect of ensuring heat preservation and easy control of hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

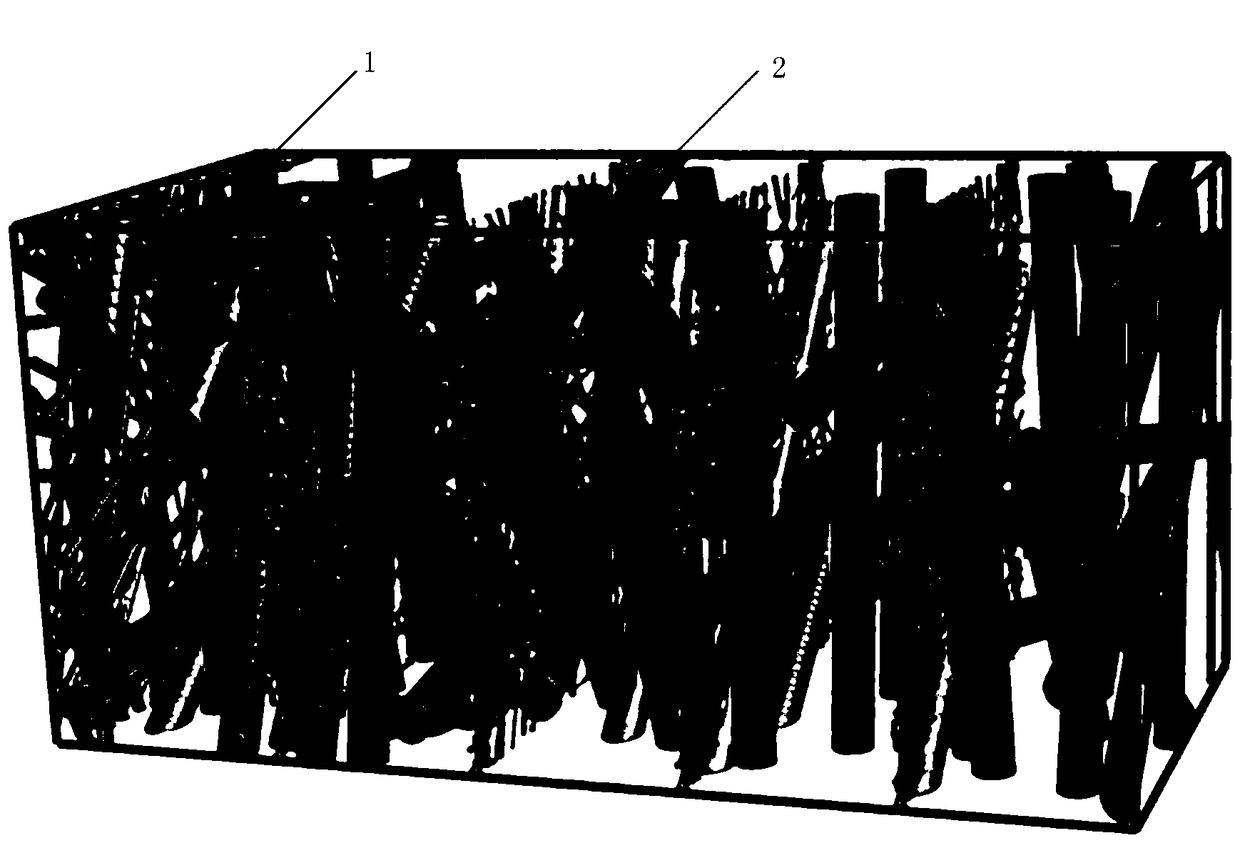

[0035] (1) Preparation of coarse denier fiber layer

[0036] The viscose fiber, ES fiber and three-dimensional crimped polyester fiber (pet) were mixed according to the ratio shown in Table 1, opened, carded and cross-laid into a coarse denier fiber layer, and deposited on the receiving net curtain; Rubber fiber is 1.67dtex, 38mm; ES fiber (PE / PP sheath-core bicomponent fiber) is 3.3dtex, 38mm; PET fiber is 6.7dtex, 38mm;

[0037] Table 1

[0038]

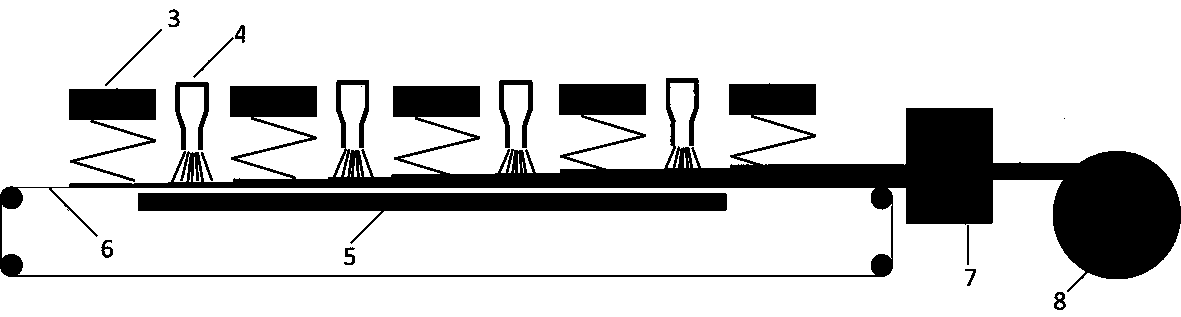

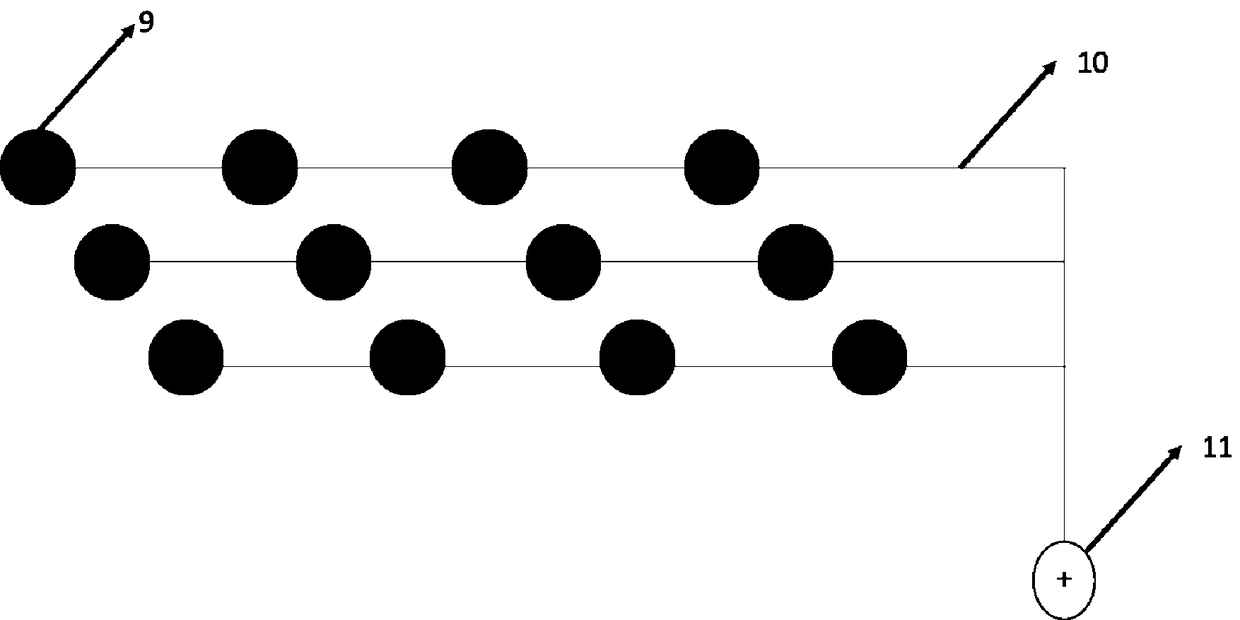

[0039] (2) Preparation of nanofiber layer

[0040] Put 5 parts of PVA resin into 95 parts of water at 90°C and stir for 30 minutes to obtain a spinning solution; add the spinning solution to the electrospinning device, and set the spinning voltage at the high-voltage power supply to 35KV to ensure that the wires are connected The spinning voltage between the spinning needle and the grounding device can ensure the continuous ejection of nanofibers. The ambient temperature is set at 26°C, and the flow rate of the spinning needle...

Embodiment 2

[0047] The difference between Example 2 and Example 1 lies in the different proportions of cotton fibers, ES fibers and three-dimensional crimped polyester fibers (pet) in the blended fiber layer, as shown in Table 2.

[0048] Table 2

[0049] .

Embodiment 3

[0051] The difference between embodiment 3 and embodiment 1 is that the proportions of hemp fiber, ES fiber and three-dimensional crimped polyester fiber (pet) in the blended fiber layer are different, as shown in table 3;

[0052] table 3

[0053] .

[0054] Product performance testing and analysis

[0055] The thermal insulation test adopts the YG606 flat-plate heat preservation instrument, the moisture permeability test adopts the moisture absorption method, and the YG501N-II textile moisture permeability tester is used, and the air permeability test adopts the YG461E-IIL automatic air permeability tester.

[0056] Table 4 Product Parameters

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com