Vacuum glass with mounting holes

A technology of vacuum glass and installation holes, which is applied in the improvement of windows/doors, climate change adaptation, windows/doors, etc., can solve the problems of increasing the use cost of vacuum glass components, restricting the installation form of vacuum glass components, and reducing the efficiency of vacuum glass. , to reduce the thermal bridge effect, ensure the sound insulation effect, and achieve the effect of easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

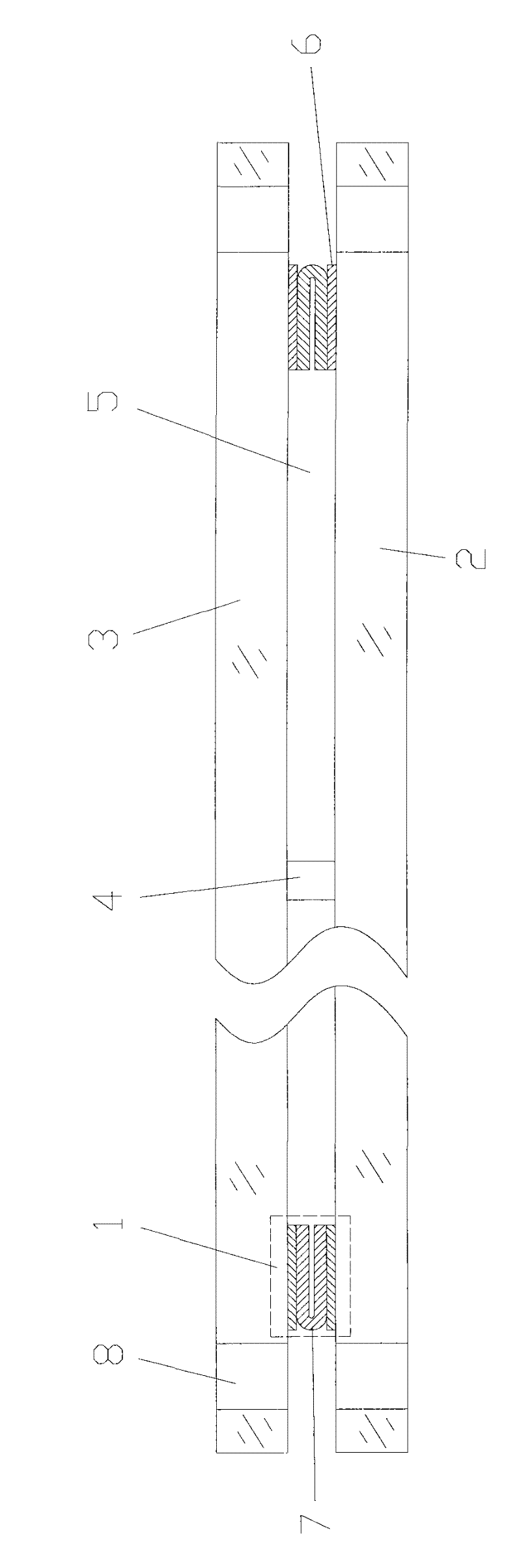

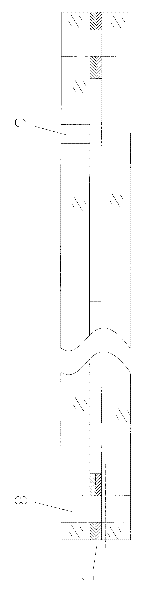

[0028] exist figure 2 In the shown embodiment 1, the vacuum glass is composed of the lower glass plate 2 and the upper glass plate 3, and the sealing edge 1 near the edge of the upper and lower glass plates 2 and 3 is made of metal solidified on the surface of the glass plate. The metalized layer 6 and the metal sealing sheet 7 with a U-shaped cross-section are formed. Both sides of the metal sealing sheet 7 and the metallized layer 6 on the upper and lower glass plates are airtightly welded and connected by a metal brazing process. The hole 8 is arranged outside the sealing edge 1 , and the installation hole 8 is isolated from the vacuum space 5 by the sealing edge 1 .

[0029] The metallized layer 6 is consolidated on the surface of the glass plate to be sealed. The metallized layer 6 is sintered on the surface of the glass plate through a sintering process. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com