Thermal barrier coating with double-layer gradient structure and preparation technology thereof

A gradient structure, thermal barrier coating technology, applied in metal material coating process, coating, superimposed layer plating, etc., can solve the problems of poor fracture toughness, short life of TBC, etc., and achieve long-life collaborative design, feasible Strong, fast realization of the effect of engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific examples given by the inventors. It should be noted that these examples are preferred examples of the present invention for those skilled in the art to understand the present invention, but the present invention is not limited to these examples.

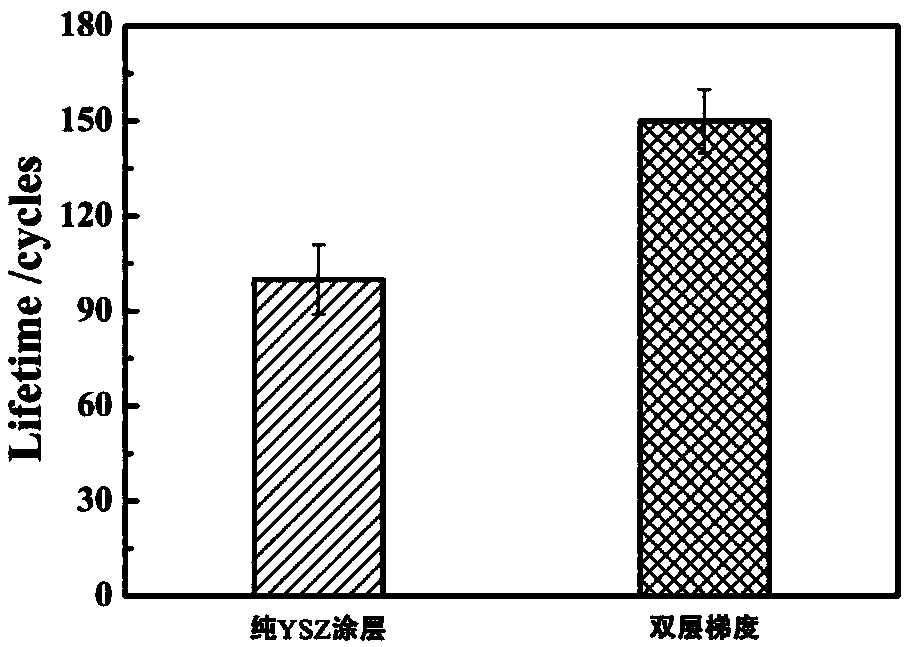

[0029] see figure 1 As shown, the present invention provides a preparation process of a double-layer gradient structure thermal barrier coating, comprising the following steps:

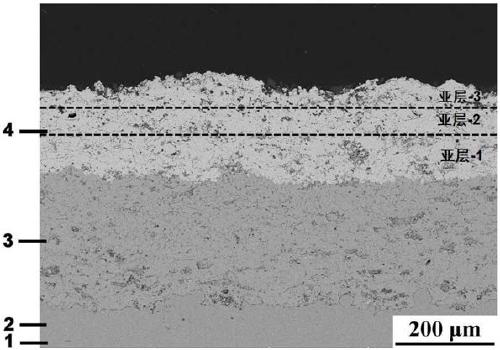

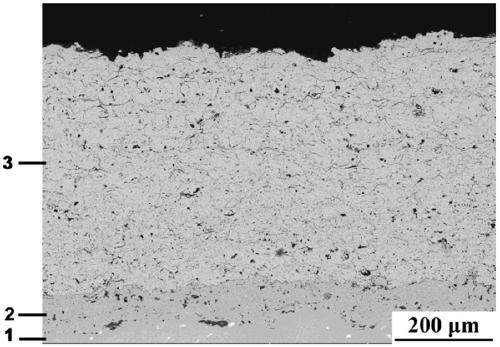

[0030] First, a metal bonding layer 2 with a thickness of 100 μm is prepared on the surface of a cylindrical superalloy substrate 1 (φ25.4mm×3mm) by a low-pressure plasma spraying process.

[0031] Subsequently, the first layered thermal insulation layer 3 with a thickness of 200 μm and an interlayer bonding rate of 30% was prepared by spraying with 8YSZ spherical hollow spray powder with a particle size of 45 μm to 75 μm by atmospheric plasma technology.

[0032] Next, lanthanum zirconate (LZO) powder with a particle size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com