Large size sapphire crystal preparing technology and growing apparatus thereof

A sapphire crystal and growth device technology, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problems of poor process repeatability, many defects, high cost, etc., to improve integrity and quality, reduce defects and impurities , to avoid the effect of crystal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

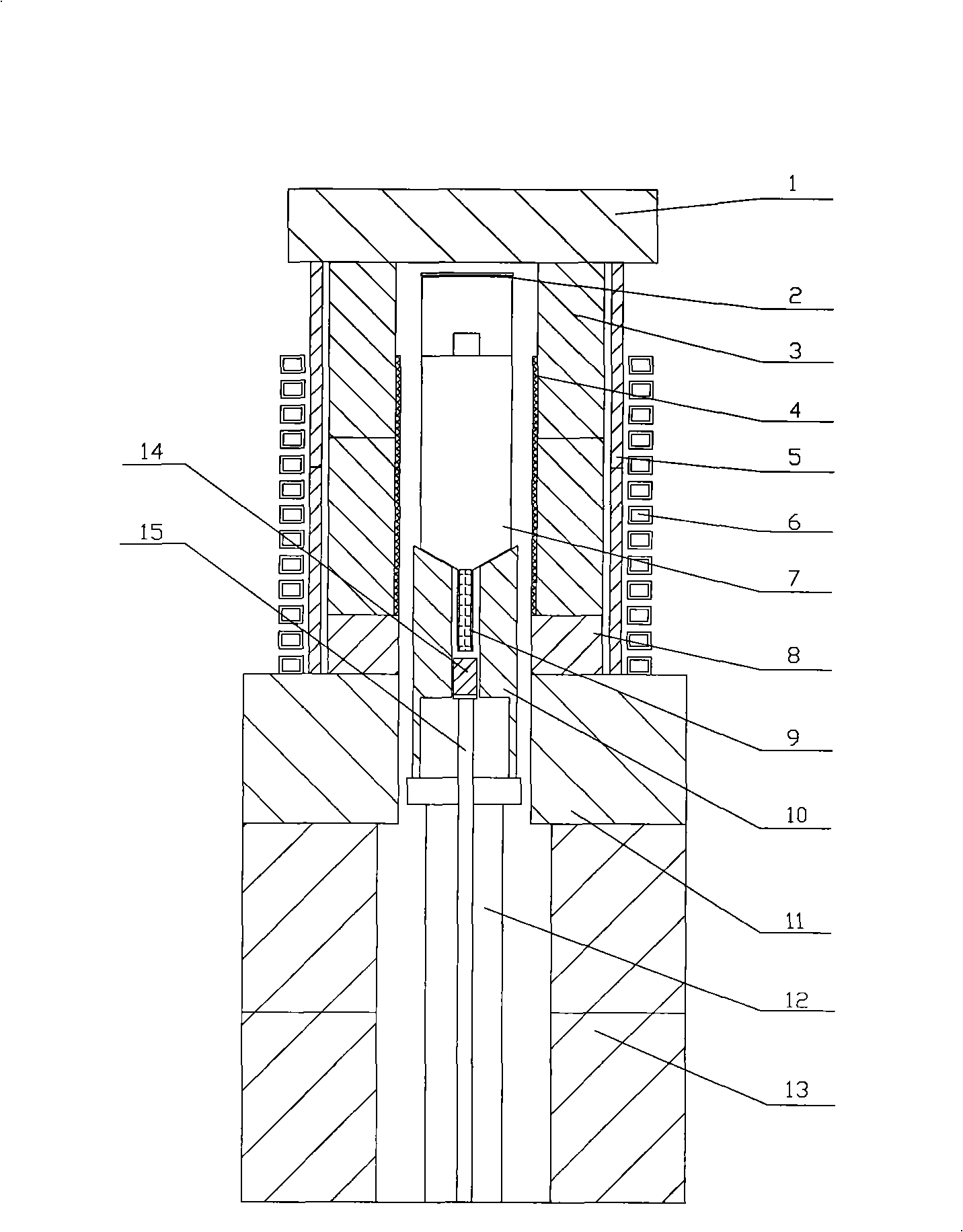

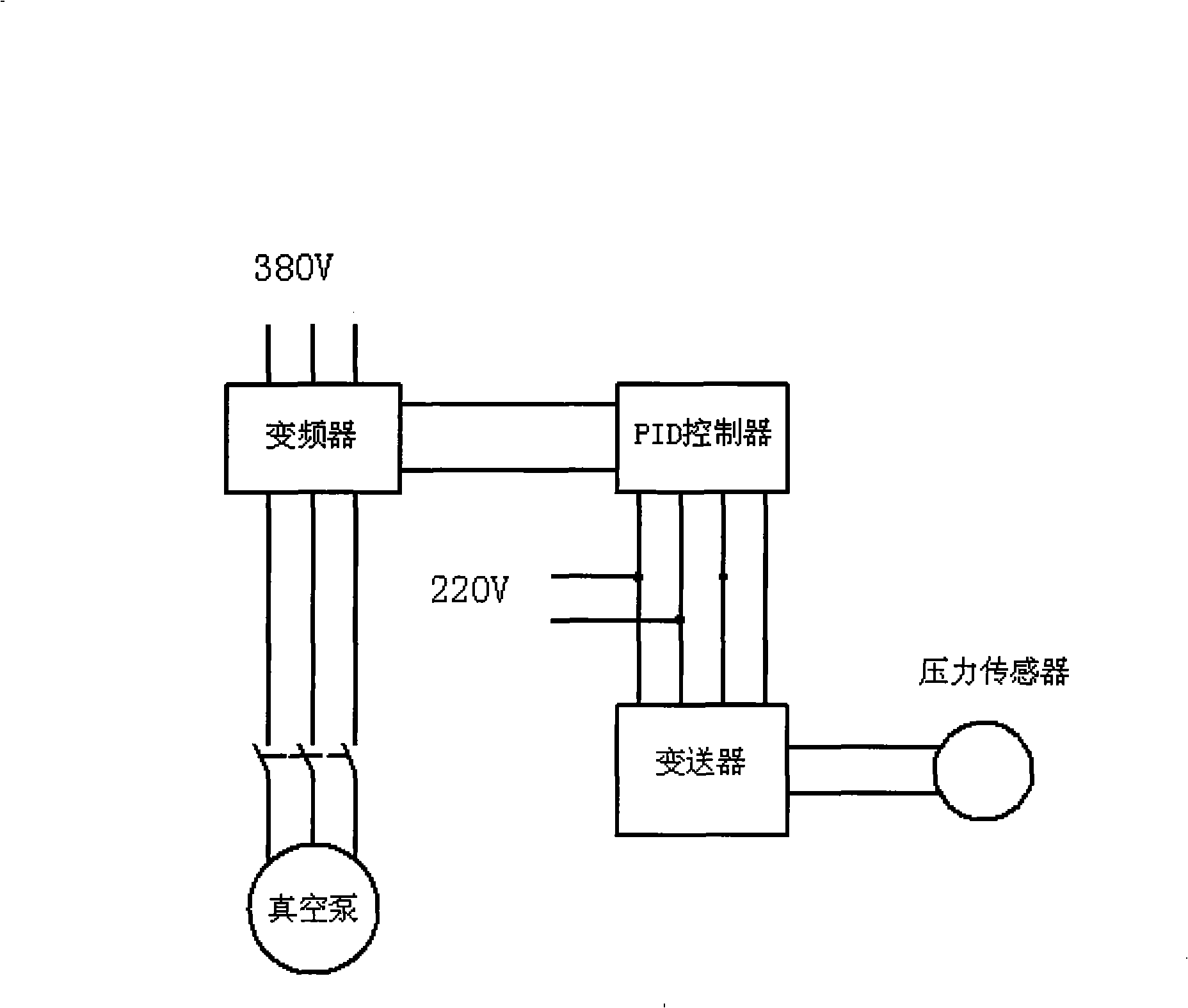

[0022] The following steps are used to prepare large-sized sapphire crystals:

[0023] (1) Put the weighed high-purity aluminum oxide (Al2O3) (purity ≥ 99.995%) into a molybdenum crucible, and vacuum until the air pressure in the furnace is less than 10 -3 Pa, filled with protective atmosphere Ar or N 2 or He or H 2 or Ar+2%H 2 , until the furnace pressure is -90~+20KPa (relative to atmospheric pressure is 0), the protective atmosphere adopts a non-flowing method.

[0024] (2) Induction heating, the heating rate is 500W~1000W / h, after the raw material is fully melted, keep the temperature constant for 3~5h;

[0025] (3) The heat preservation under the seed crystal in the furnace is lowered by 15-120mm, and then the molybdenum crucible is lowered, and the lowering distance is the height of the crucible, and the lowering rate is 0.5-3.0mm / h;

[0026] (4) Cool down, the temperature in the furnace drops to 1600-1750°C, and the cooling rate is 100W-300W / h;

[0027] (5) The mol...

Embodiment 2

[0032] The following steps are used to prepare large-sized sapphire crystals:

[0033] (1) the weighed high-purity aluminum oxide (Al 2 o 3 ) (purity ≥ 99.995%) into a molybdenum crucible, vacuum until the pressure in the furnace is less than 10 -3 Pa, fill the protective atmosphere Ar until the furnace pressure is -90 ~ +20KPa (relative atmospheric pressure is 0), and the atmosphere adopts a non-flowing method;

[0034] (2) Induction heating, the heating rate is 1000W / h, after the raw material is fully melted, keep the temperature constant for 3~5h;

[0035] (3) The lower heat preservation of the seed crystal in the furnace is lowered by 15-120 mm, and then the molybdenum crucible is lowered, and the lowering distance is the height of the crucible, and the lowering rate is 3.0 mm / h;

[0036] (4) Cool down, the temperature in the furnace drops to 1600°C, and the cooling rate is 100WW / h;

[0037] (5) The molybdenum crucible is returned to the heating zone, annealed in situ,...

Embodiment 3

[0041] The following steps are used to prepare large-sized sapphire crystals:

[0042] (1) the weighed high-purity aluminum oxide (Al 2 o 3) (purity ≥ 99.995%) into a molybdenum crucible, vacuum until the pressure in the furnace is less than 10 -3 At Pa, the protective atmosphere is Ar plus 2% H 2 Until the furnace pressure is -90~+20KPa (relative atmospheric pressure is 0), the atmosphere adopts a flow method to ensure that the pressure in the furnace meets the process requirements.

[0043] (2) Induction heating, the heating rate is 500W / h, and after the raw materials are fully melted, the temperature is kept constant for 3 to 5 hours;

[0044] (3) The lower heat preservation of the seed crystal in the furnace is lowered by 15-120 mm, and then the molybdenum crucible is lowered, and the lowering distance is the height of the crucible, and the lowering rate is 0.5 mm / h;

[0045] (4) Cool down, the temperature in the furnace drops to 1750°C, and the cooling rate is 300W / h;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com