Sleeve installed on medium carriage

A technology of sleeves and carriages, applied in positioning devices, clamping, supporting, etc., can solve the problems of high labor intensity and time delay, and achieve the effect of simple manufacturing method, low cost and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

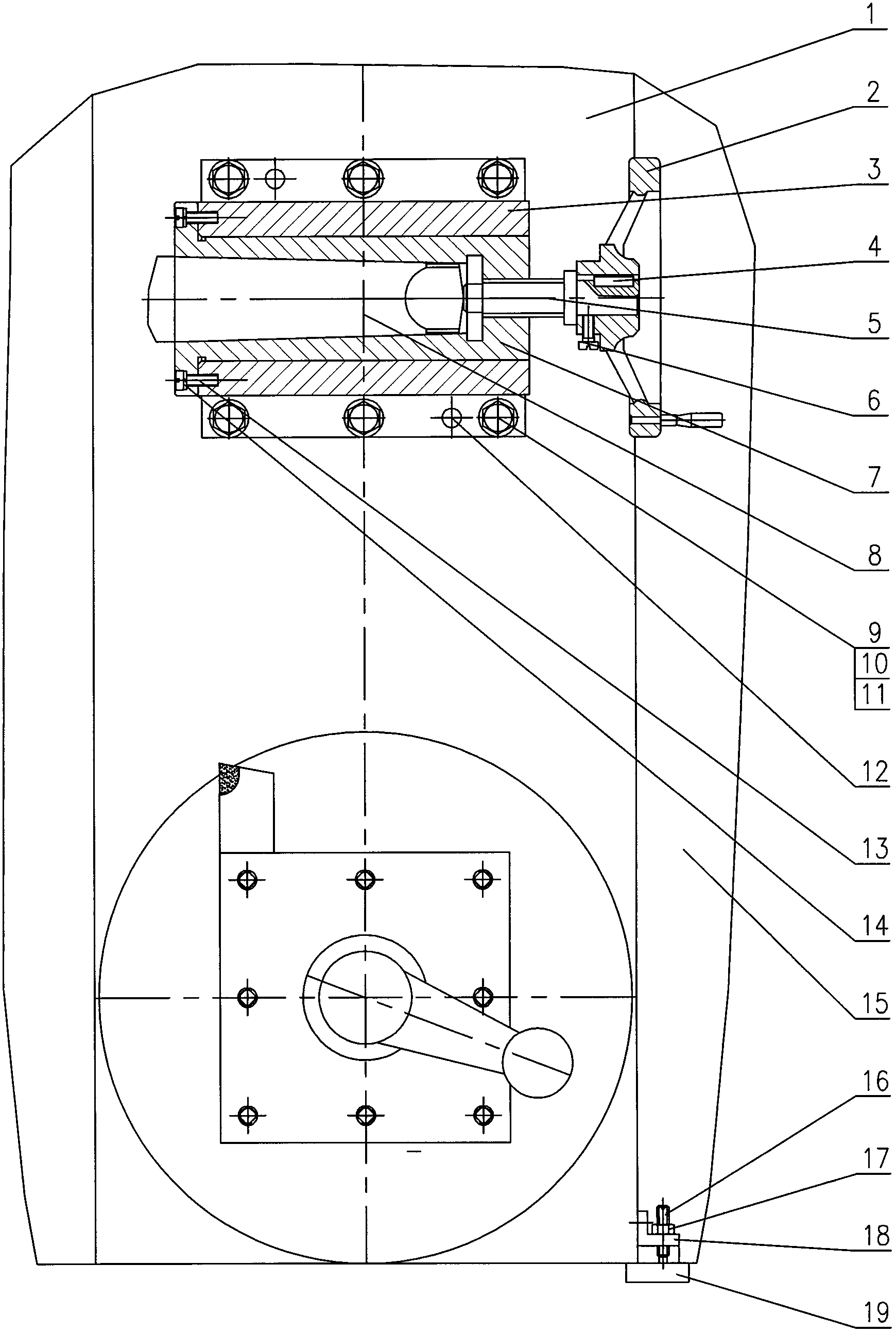

[0011] The quick tool unloader of the lathe is installed on the middle carriage (1) of the lathe and moves together with the large sliding plate (15) of the lathe to realize automatic tool feeding. In the accompanying drawings, the seat (3) is fixed on the carriage (1) in the lathe with a flat washer (10), a large spring washer (11), an internally threaded tapered pin (12) and a bolt (9), and the knife barrel (7 ) is fixed in the inner hole of the seat (3) with a slotted cylindrical head screw (13) and a small spring washer (14), the fit is H7 / h6, and the heat treatment of the knife cylinder (7) is 48~52HRC. The axis of the tapered hole of the tool barrel (7) where the tool (8) is installed is coaxial with the axis of rotation of the lathe spindle, and the hand wheel (2) is fixed on the wire with a common flat key (4) and a slotted cylindrical head shaft screw (6). On the cylinder on the left side of the bar (5), the stud on the right side of the lead screw (5) is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com