Bi-metal composite pouring bent pipe used for concrete conveying and manufacturing method

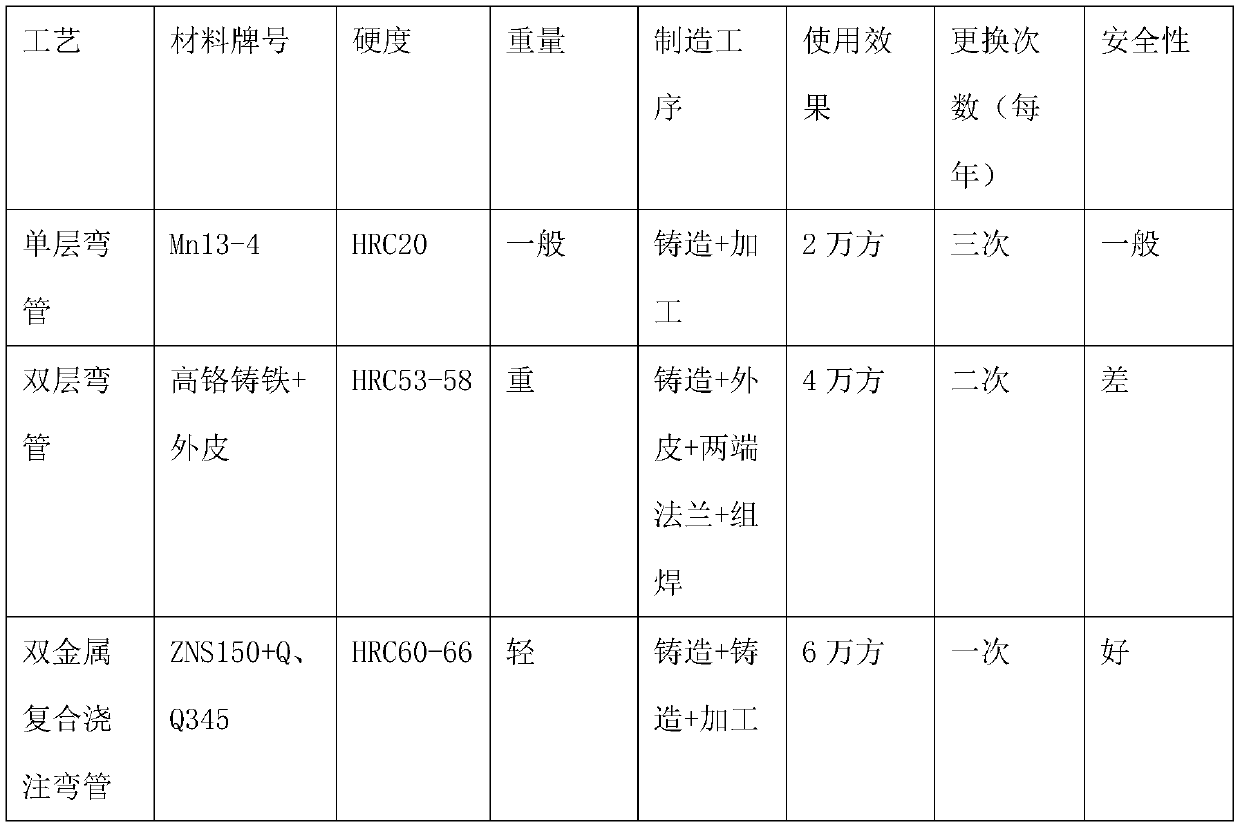

A bimetal and concrete technology, applied in the direction of elbows, pipe components, siphons, etc., can solve the problems of slag inclusions, air holes, damage to the installation and positioning of lining pipes, and reduce the service life of elbows in interlayer metals, so as to improve Safety and stability, prevent separation and fall off, and reduce the effect of failure rate in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

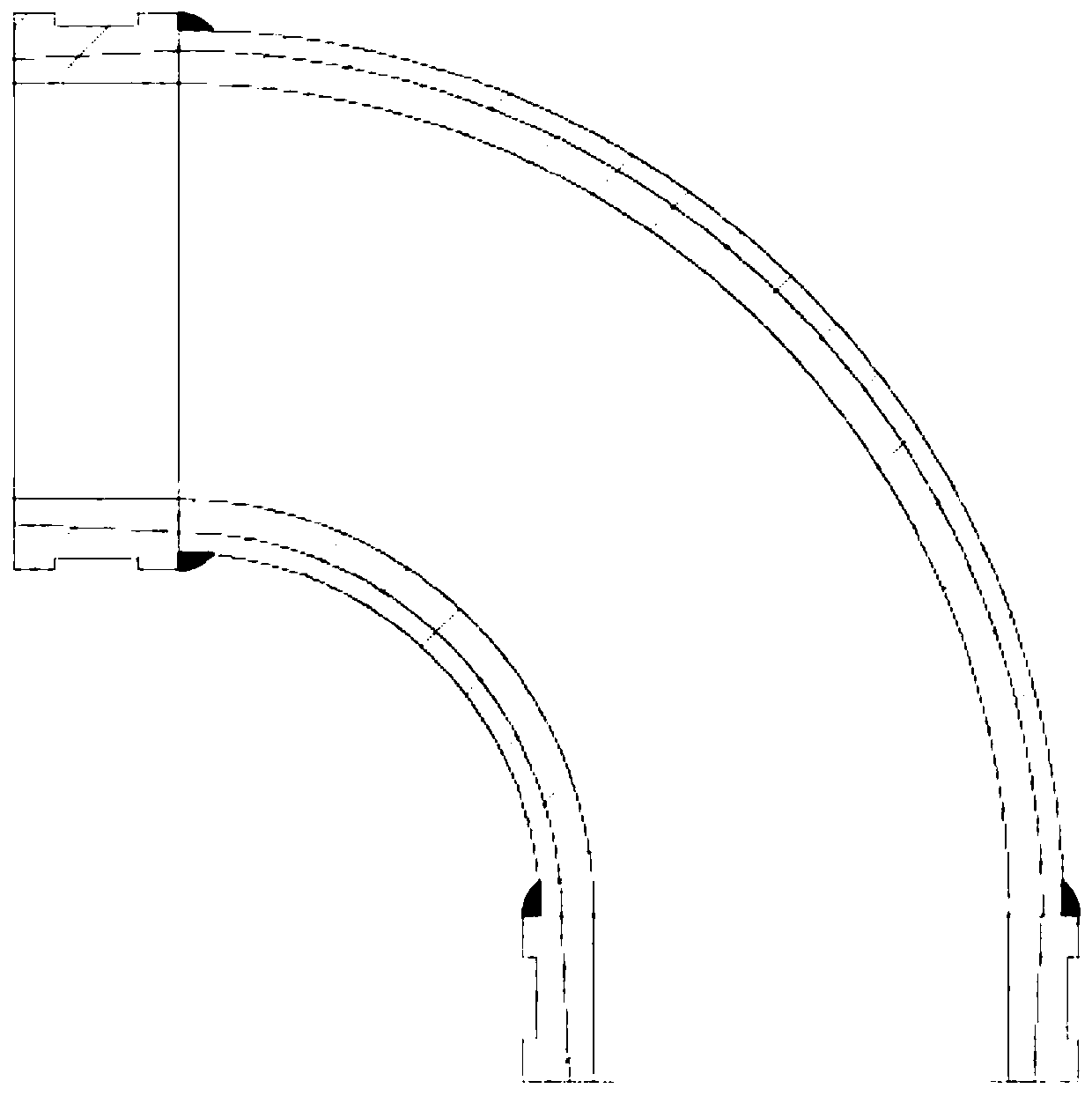

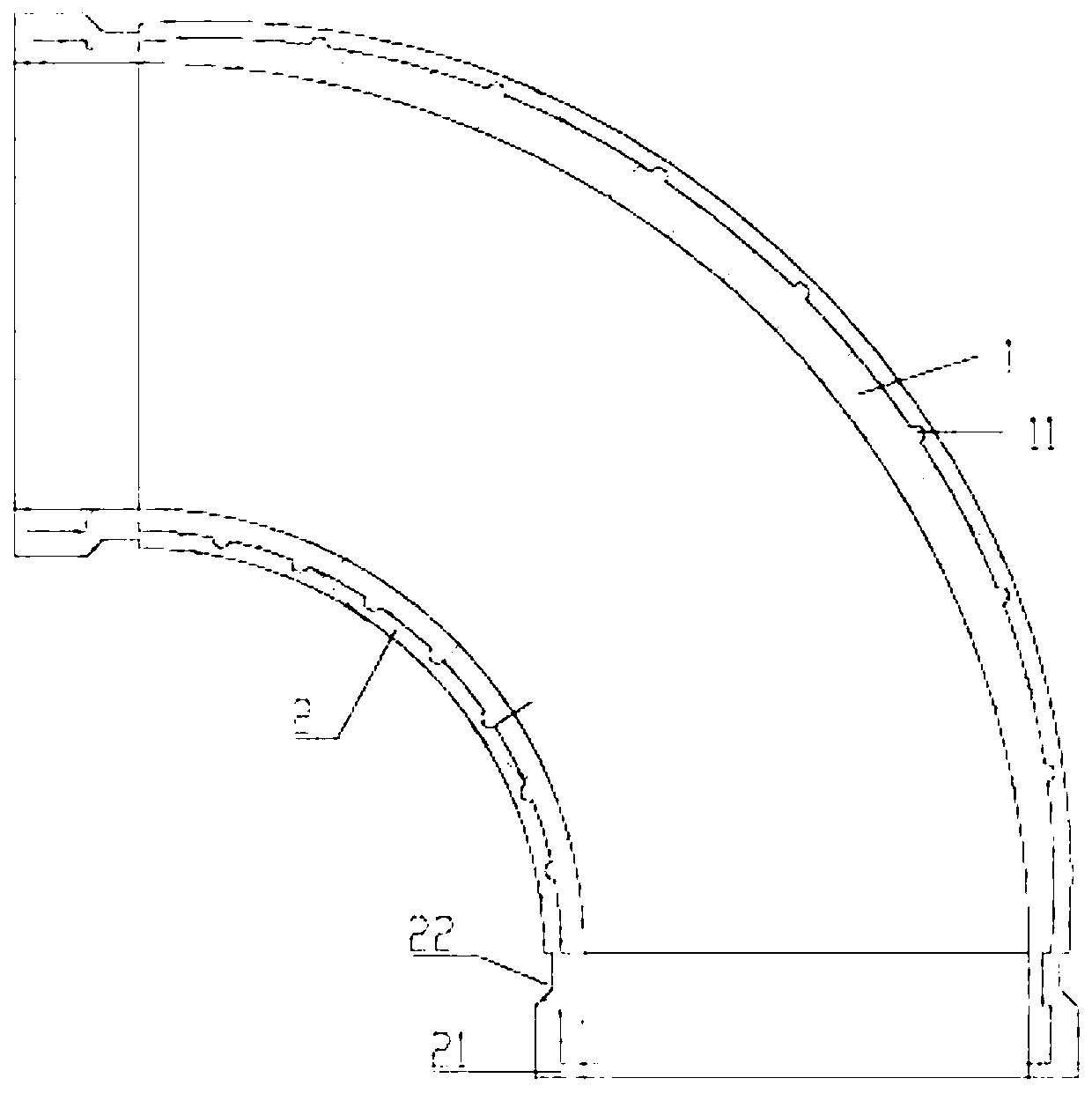

[0028] Such as figure 2 As shown, the bimetallic composite casting elbow used for concrete delivery in this embodiment includes an inner tank 1 and a shell 2 that covers the inner tank 1 by casting, and the wall thickness of the inner tank 1 is along the circumferential direction From the inner arc to the outer arc of the elbow, and from the two ends of the elbow to the middle in the axial direction, it is gradually thickened. The surface of the inner liner 1 is provided with a bite rib 11 that facilitates the engagement of the outer shell 2. The outer shell 2 Both ends are provided with joint rings 21 for sealing the end face of the liner 1 with inner buckles. The crimping ribs 11 are several raised rings axially distributed along the outer wall of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com