Composite high-strength glass fiber reinforced cement decoration, fireproof and explosion-proof board and its production line

A high-strength glass fiber and reinforced cement technology, which is applied in the field of building materials, can solve the problems that the outer layer of the metal is easy to rust and discolor, cannot be used on the outer wall surface, and cannot maintain the aesthetics, etc., to achieve light weight and scientific and reasonable manufacturing methods , easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

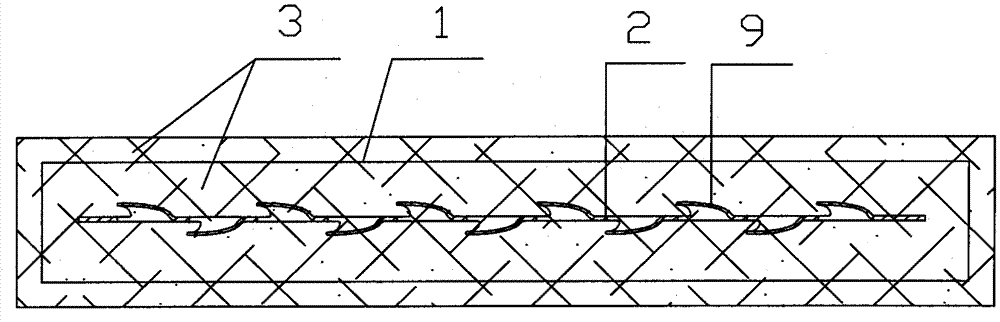

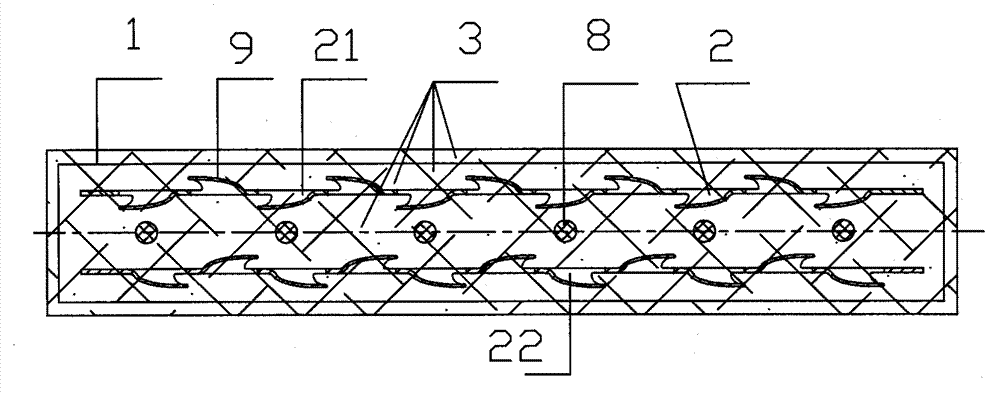

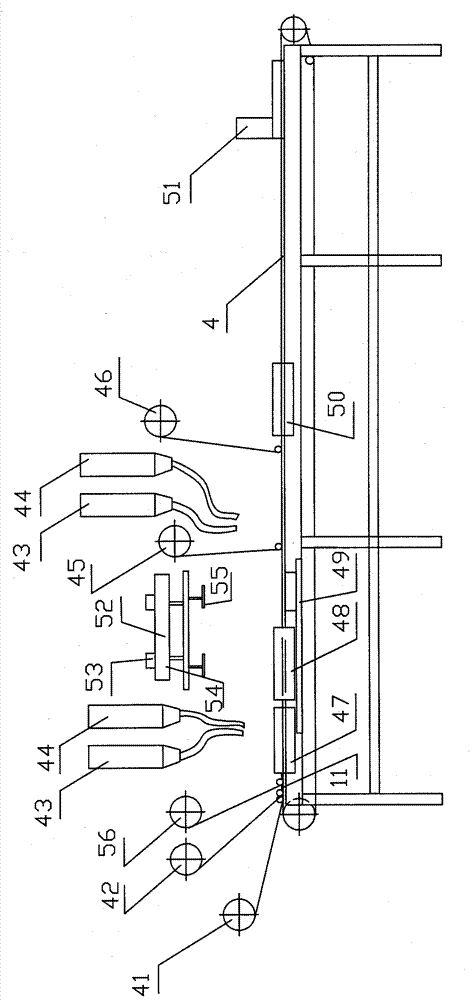

[0016] figure 1 It is a structural sectional view of an embodiment of the present invention. In the figure, a composite high-strength glass fiber reinforced cement decoration, fireproof and explosion-proof board, which includes: a cavity structure 1 surrounded by glass fiber mesh cloth, a metal layer 2, and glass fiber chopped strands embedded in the cement slurry The coagulation layer 3; the metal layer is plate-shaped, and the plate body is provided with a number of horizontally arranged fins 9 that are punched outward and have openings at a certain distance. In this embodiment, the metal layer is One layer, the fins 9 arranged in the same horizontal direction on the plate body protrude to one side of the plate body, and the adjacent fins 9 arranged in the same horizontal direction protrude to the other side of the plate body. The direction of the fins is not limited. The positions of can be arranged in a matrix or in a misplaced arrangement, and in this example, they are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com