High density glass fiber reinforced cement curved plate and manufacturing method thereof

A technology of glass fiber and manufacturing method, which is applied in the field of high-density glass fiber reinforced cement curved board and manufacturing, can solve the problem that the cement board is difficult to meet its requirements, and achieve the advantages of easy construction site installation, high efficiency, low cost and high economic benefit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

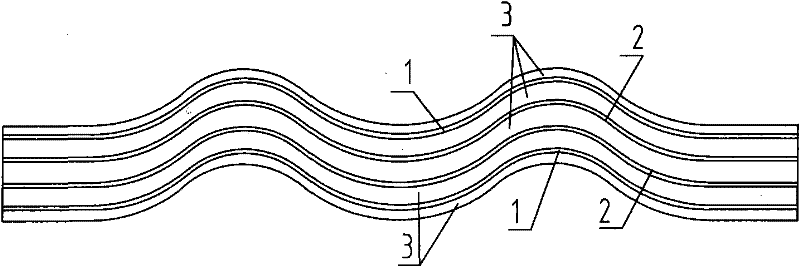

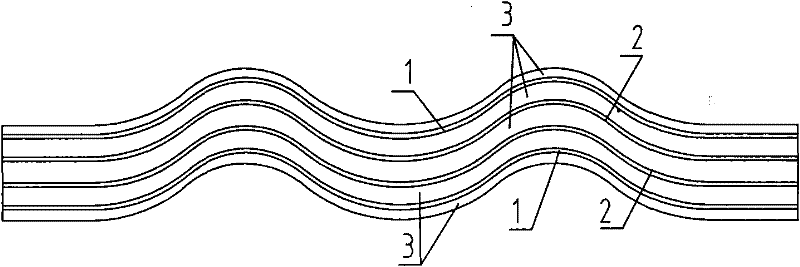

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, and cement board product specification is 1200 * 2400 * 12mm in the present embodiment, as figure 1 As shown, its structural form is: the structure of the high-density glass fiber reinforced cement board is a frame structure with a sinusoidal curved surface of equal cross-section formed by glass fiber mesh 1 cloth, and two layers of long glass fibers with the same curved surface are arranged in the frame structure. Layer 2, between the two layers of curved glass long fiber layers 2, between the curved glass long fiber layer 2 and the upper and lower curved glass fiber mesh cloth 1, and the upper and lower curved glass fiber nets The outer layer of the grid cloth 1 is provided with a coagulation layer 3 of the same curved surface cement slurry and glass fiber chopped strands.

[0031] The present invention adopts following steps to produce:

[0032] ① Measuring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com