Wood-plastic composite floor and preparation method thereof

A wood-plastic composite and manufacturing method technology, applied in the direction of floor, building, building structure, etc., to achieve the effect of saving wood resources, small color difference, and improving decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described

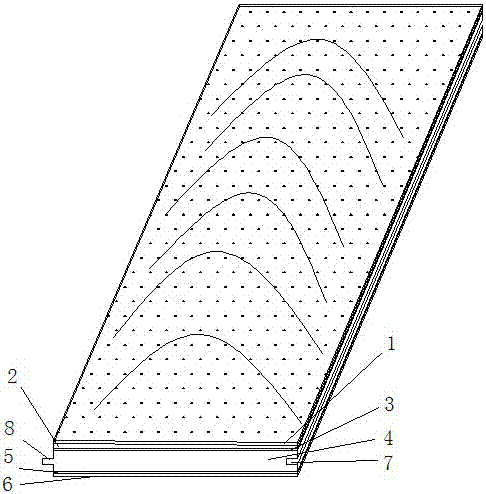

[0019] refer to figure 1 , a wood-plastic composite flooring of the present invention, comprising: from top to bottom sequentially by the surface finish layer 1, the upper surface layer 2, the upper surface modified layer 3, the middle layer 4, the lower surface modified layer 5 and The lower surface layer is composed of 6 composites.

[0020] A kind of manufacturing method of wood-plastic composite floor of the present invention, comprises content to have:

[0021] 1) The structure of the upper surface layer and the lower surface layer is the same, and the veneer of any tree species is planed, rotary cut and sawed. The thickness is 2~8 mm. Time 1~4 hours, carry out carbonization treatment;

[0022] 2) Paint the upper surface modified layer on the lower surface of the upper surface layer, and paint the lower surface modified layer on the upper surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com