Process for mfg, 18k manganese zine iron oxygen body magnetic powder magnetic core

A technology of manganese zinc ferrite and its manufacturing method, which is applied in the direction of the magnetism of inorganic materials, can solve difficult problems and achieve the effect of improving the frequency characteristics and making the manufacturing method scientific and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

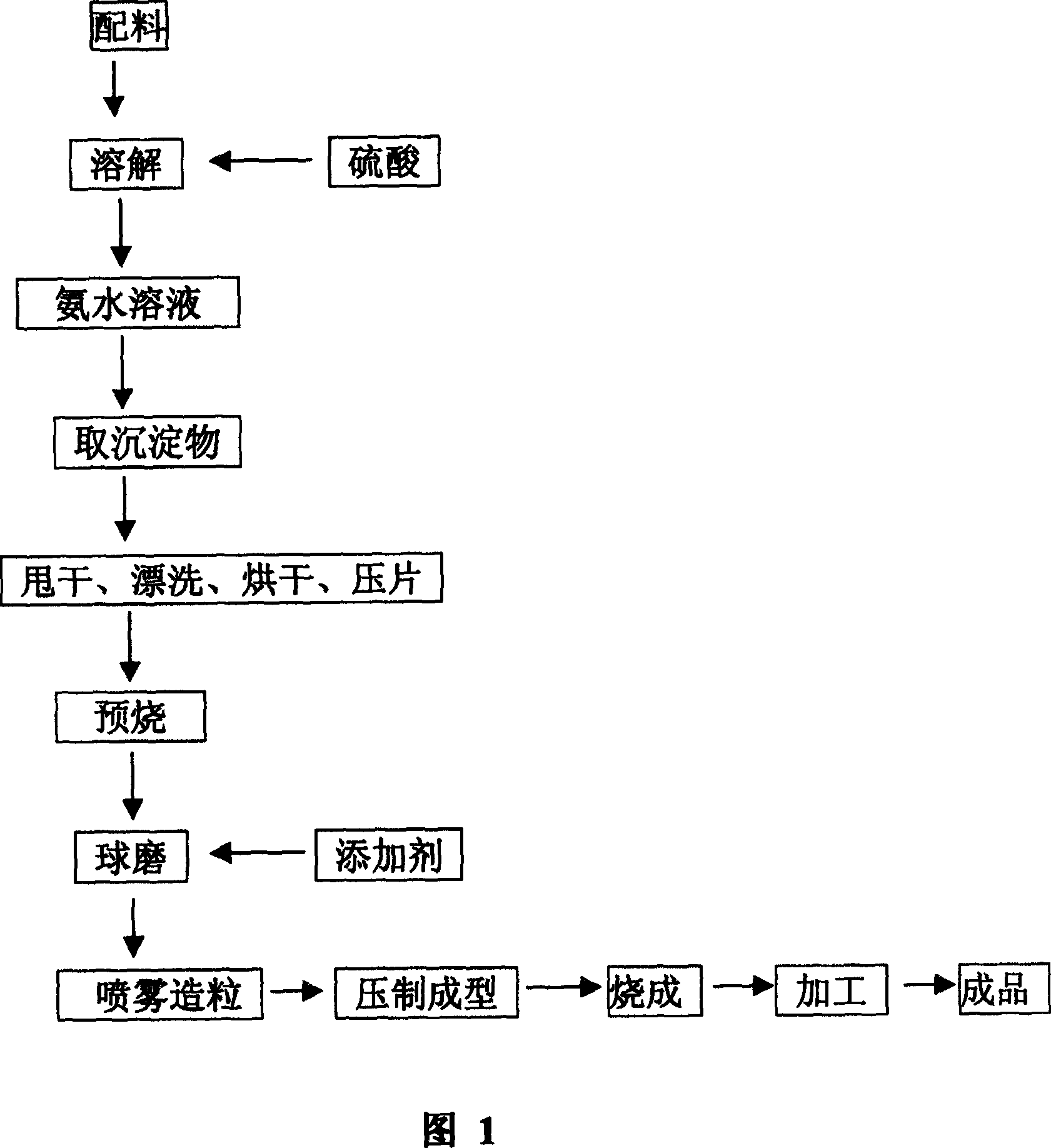

[0024] The manufacturing method of the 18k MnZn ferrite magnetic powder magnetic core of the present invention comprises batching, dissolving, precipitating, pre-burning, pulverizing, molding and firing, and the specific technological process is:

[0025] Fe 2 o 3 52.5%, MnO 26.5% and ZnO 21.0% for batching, iron sheets, zinc ingots, and electrolytic manganese were dissolved in dilute sulfuric acid in sequence to obtain a working solution. The weight ratio of sulfuric acid to water in dilute sulfuric acid was 1:6.6, molar The concentration is 2.6 mol%.

[0026] Inject the working solution into the precipitant composed of ammonium bicarbonate solution and ammonia solution for precipitation. The density of the ammonium bicarbonate solution is 1.41g / ml, the ratio of the working solution to the ammonium bicarbonate solution is 1:1, and the density of the ammonia solution 0.920g / ml, the ratio of the working solution to the ammonia solution is 1:0.15; the pH value of the solution...

Embodiment 2

[0041] The manufacturing method of the 18k MnZn ferrite magnetic powder magnetic core of the present invention comprises batching, dissolving, precipitating, pre-burning, pulverizing, molding and firing, and the specific technological process is:

[0042] Fe 2 o 3 53%, MnO 26% and ZnO 21% in batching proportions, iron sheets, zinc ingots, and electrolytic manganese were dissolved in dilute sulfuric acid in sequence to obtain a working solution. The weight ratio of sulfuric acid to water in dilute sulfuric acid was 1:6.7.

[0043] Inject the working solution into the precipitant composed of ammonium bicarbonate solution and ammonia solution for precipitation. The density of the ammonium bicarbonate solution is 1.4g / ml, the ratio of the working solution to the ammonium bicarbonate solution is 1:1, and the density of the ammonia solution 0.920g / ml, the ratio of the working solution to the ammonia solution is 1:0.15; the pH value of the control solution is 6.9.

[0044] The sed...

Embodiment 3

[0057] The manufacturing method of the 18k MnZn ferrite magnetic powder magnetic core of the present invention comprises batching, dissolving, precipitating, pre-burning, pulverizing, molding and firing, and the specific technological process is:

[0058] Fe 2 o 3 52.8%, MnO 25.7% and ZnO 21.5% in batching proportions, iron sheets, zinc ingots, and electrolytic manganese were dissolved in dilute sulfuric acid in sequence to obtain a working solution. The weight ratio of sulfuric acid to water in dilute sulfuric acid was 1:6.8.

[0059] Inject the working solution into the precipitant composed of ammonium bicarbonate solution and ammonia solution for precipitation. The density of the ammonium bicarbonate solution is 1.42g / ml, the ratio of the working solution to the ammonium bicarbonate solution is 1:1, and the density of the ammonia solution 0.9224g / ml, the ratio of the working solution to the ammonia solution is 1:0.15; the pH value of the control solution is 6.8-7.0.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com