A foam nickel-based silicon alloy sand control device and its manufacturing method

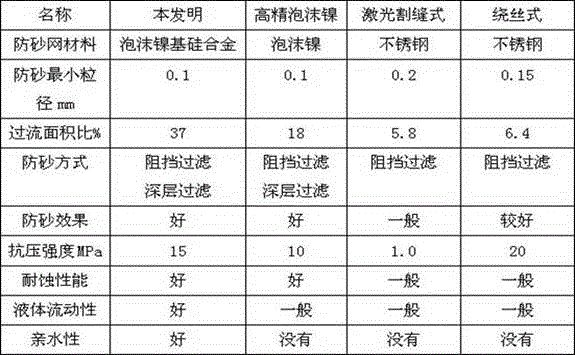

A manufacturing method and technology of nickel foam, which is applied in the direction of earthwork drilling, production fluid, wellbore/well parts, etc., can solve the problems of affecting the flow of petroleum liquid, blocking the flow of petroleum liquid, and small effective area of expansion, and achieves the goal of manufacturing method Scientific and reasonable, meet the requirements of use, good sand control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

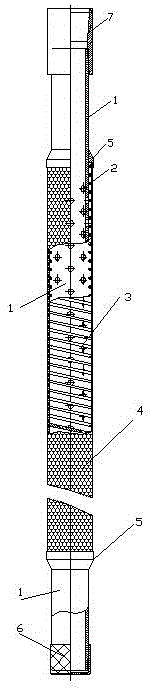

[0149] The base pipe 1 of the foamed nickel-based silicon alloy sand control device of the present invention consists of a φ73mm pipe, and the upper and lower ends of the base pipe 1 are equipped with 27 / 8 〃 Thread, 172 φ12mm through holes evenly distributed in the middle 1.0m, flow area 1.94dm 2 The φ4.5mm spiral support ring 3 is welded on the middle surface of the base pipe 1, and the foamed nickel-based silicon alloy sand control sleeve 4 is installed on it. Its working principle is that the oil liquid flows into the underground sandstone layer through the foamed nickel-based silicon alloy sand control sleeve 4, and the mesh diameter of the nickel-based silicon alloy sand control sleeve 4 prevents sand particles of a certain size in the oil liquid from passing through, and the oil liquid passes through the spiral The spiral channel of the support ring 3 enters the inner cavity of the base pipe 1 through the φ12 hole on the surface of the base pipe 1, and flows upward. Unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com