Chemical toughened glass capable of carrying out subsequent cutting

A chemical tempered glass and follow-up technology, applied in high-strength fields, can solve problems such as glass debris residue, peeling, glass surface damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] The main component of glass is SiO 2 63%, Al 2 o 3 16%, Na 2 O 13%, K 2 O 3.55%, MgO 3.95%, the rest is SnO 2 .

[0140] First, mix the corresponding raw materials according to the ingredients given in the examples in Table 1, melt the raw materials through a platinum crucible at 1600-1640°C and keep them warm for 5-15 hours, then clarify at 1640-1660°C, and then cool down to Around 1600°C. The platinum crucible was taken out from the high-temperature furnace, and the glass melt was poured into a cold stainless steel mold to obtain a bulk glass with a size of approximately 50×50×40 mm. Then put the glass along with the stainless steel mold into an annealing furnace at about 600°C for 2 to 8 hours for annealing.

[0141] The annealed glass is polished, then cut, edged, and finely planed to the required sample size, ie 40×40×0.7mm. The surface roughness after polishing is below 1 nanometer.

[0142] The coefficient of thermal expansion and the transition point ...

Embodiment 2

[0147] Glass samples were prepared in the same manner as in Example 1.

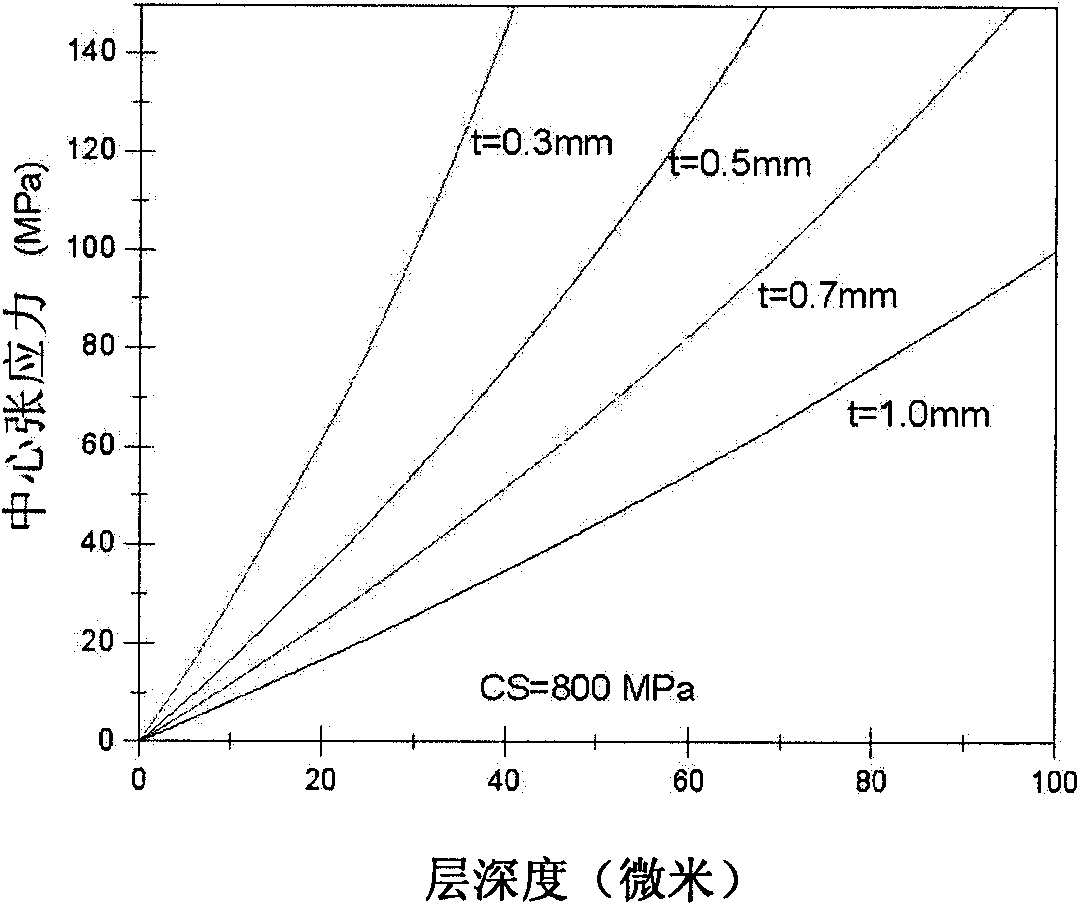

[0148] The thickness of the glass sample is 0.7mm. Pure KNO chemically tempered at 440°C 3 6 hours in a salt bath. The surface stress is 700Mpa, the central stress is 45Mpa, and the stress layer depth is 40μm.

[0149] Using CO 2 The laser is used for cutting. After adjusting the laser beam power and moving speed, the glass cannot be cut smoothly. The reason is that the depth of the stress layer and the central tensile stress are too large.

Embodiment 5

[0151] Glass samples were prepared in the same manner as in Example 1.

[0152] The thickness of the glass sample is 1.0mm. Pure KNO chemically tempered at 390°C 3 8 hours in a salt bath. The surface stress is 1000Mpa, the central stress is 10Mpa, and the stress layer depth is 10μm.

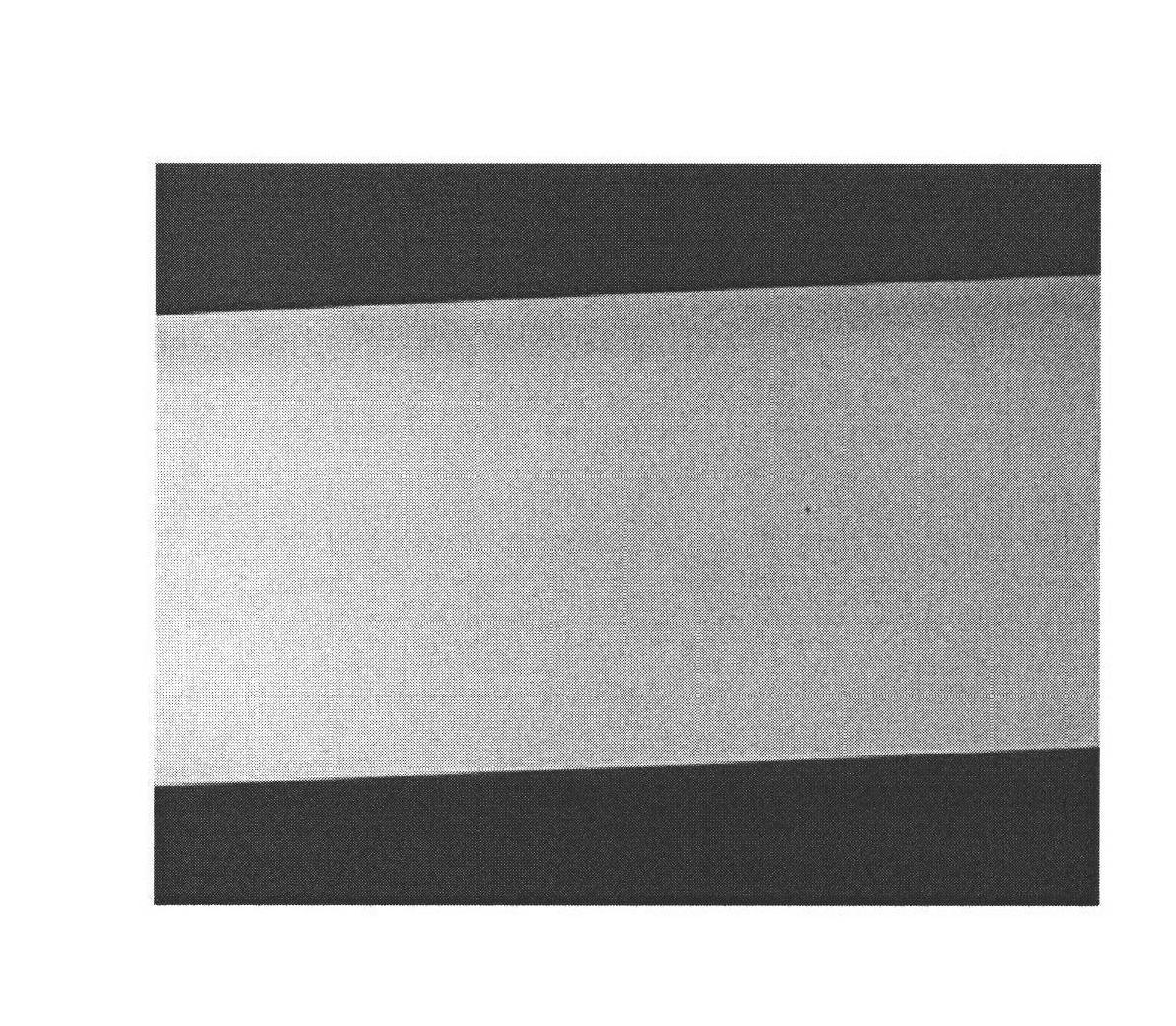

[0153] Using CO 2 The laser is used for cutting, the power of the laser is 100W, the moving speed of the laser beam is 180mm / s, and the glass can be cut smoothly. Edge quality is good. Glass edge quality is visible Figure II shown.

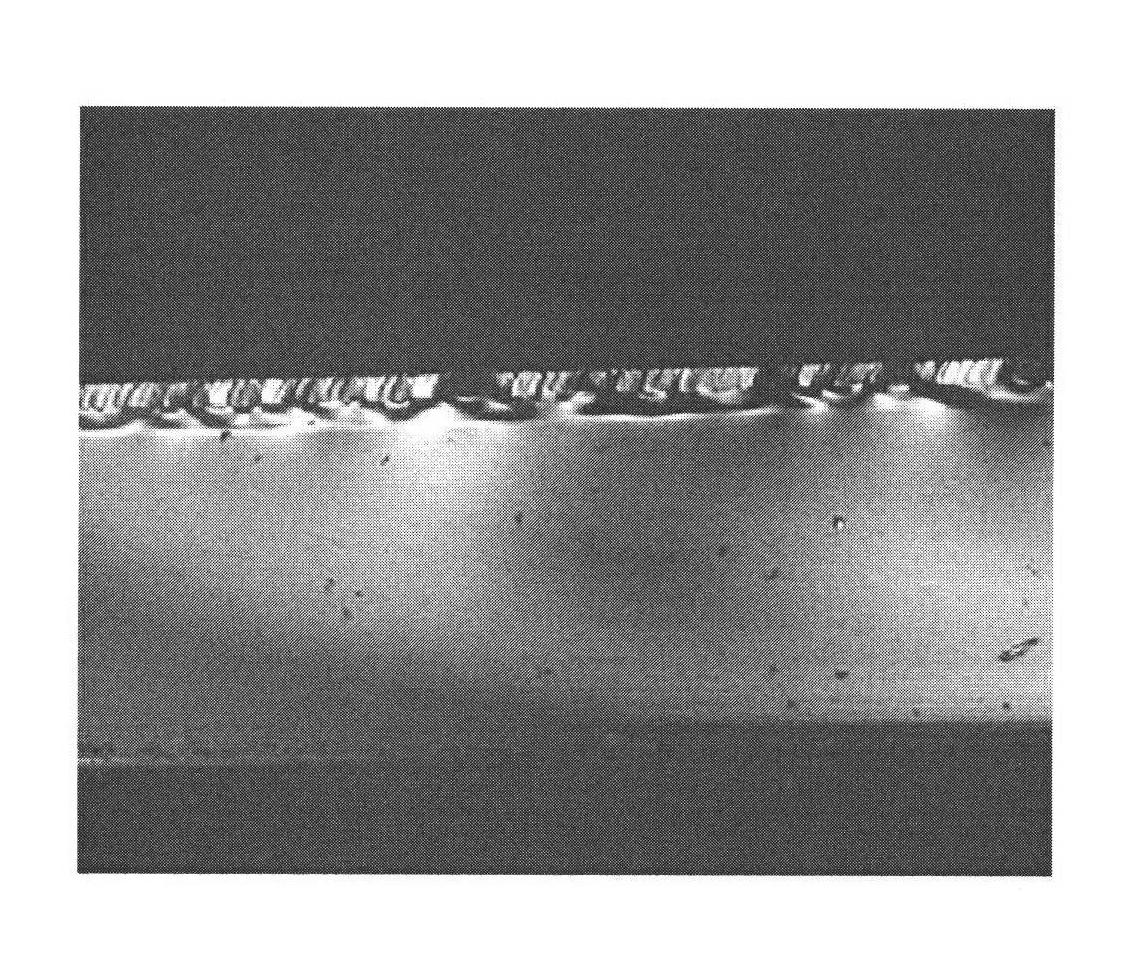

[0154] At the same time, the glass can also be cut using a conventional glass cutting table with a knife wheel, such as Figure three shown. However, there are a large number of tiny gaps at the edges, which cannot be mass-produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Surface stress | aaaaa | aaaaa |

| Depth of stress layer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com