Precipitation Hardening High Entropy Alloy and Method of Manufacturing the Same

a high entropy alloy and precipitation hardening technology, applied in the field of metal alloys, can solve the problems of manufacturing limitations, manufacturing process limitations, and the lik

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0052]First, as illustrated in Table 1, a high-entropy alloy according to Comparative Examples 1 through 3 and Inventive Examples 1 through 13 is manufactured.

[0053]Pieces of constituent pure metals weighted to attain a composition (wt %) of Table 1 were prepared, and the mixed pieces were arc melted in a vacuum atmosphere to manufacture an alloy. Hereinafter, homogenization heat treating was performed at 1050° C. for 24 hours, and rapid cooling was performed.

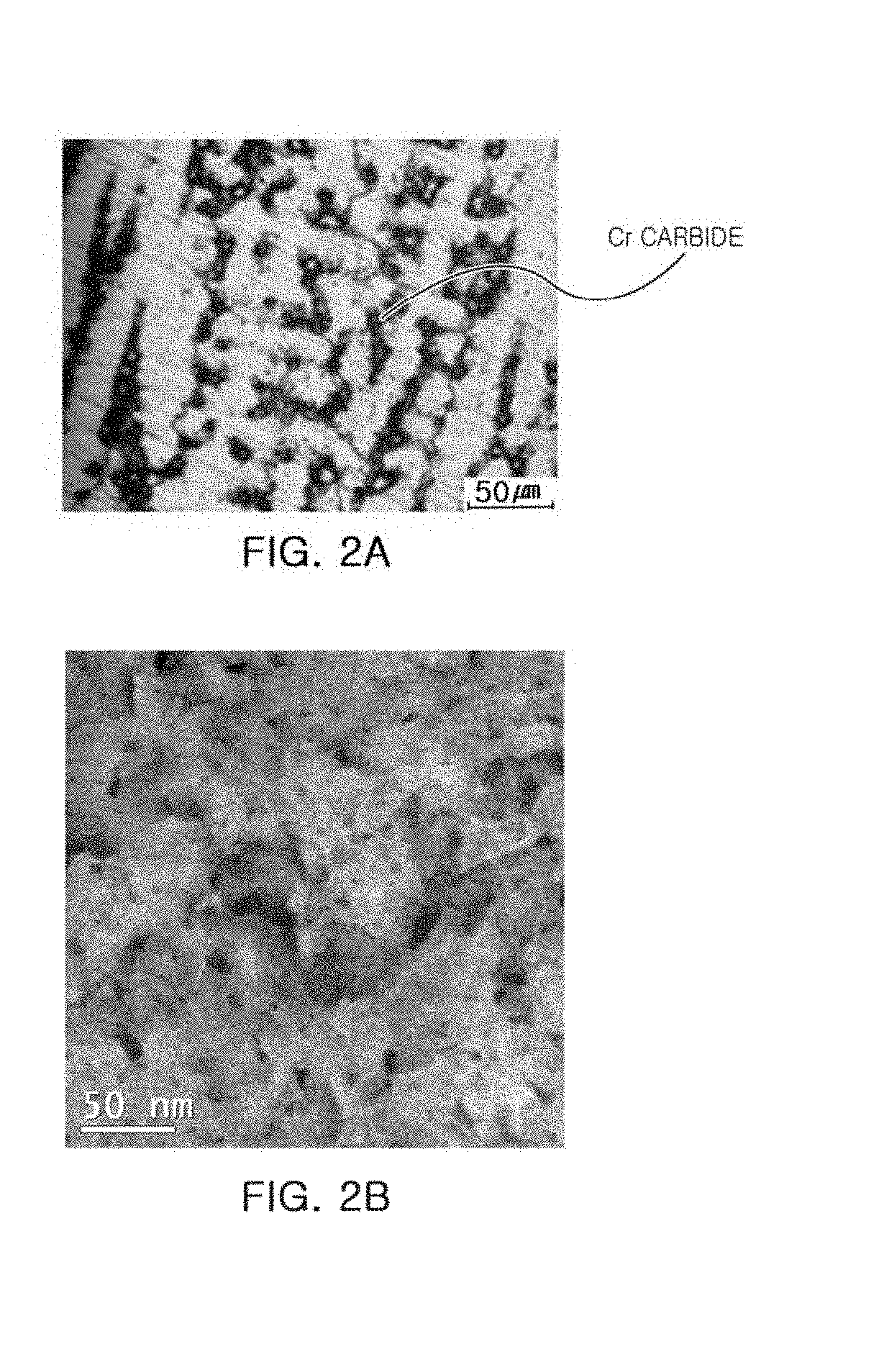

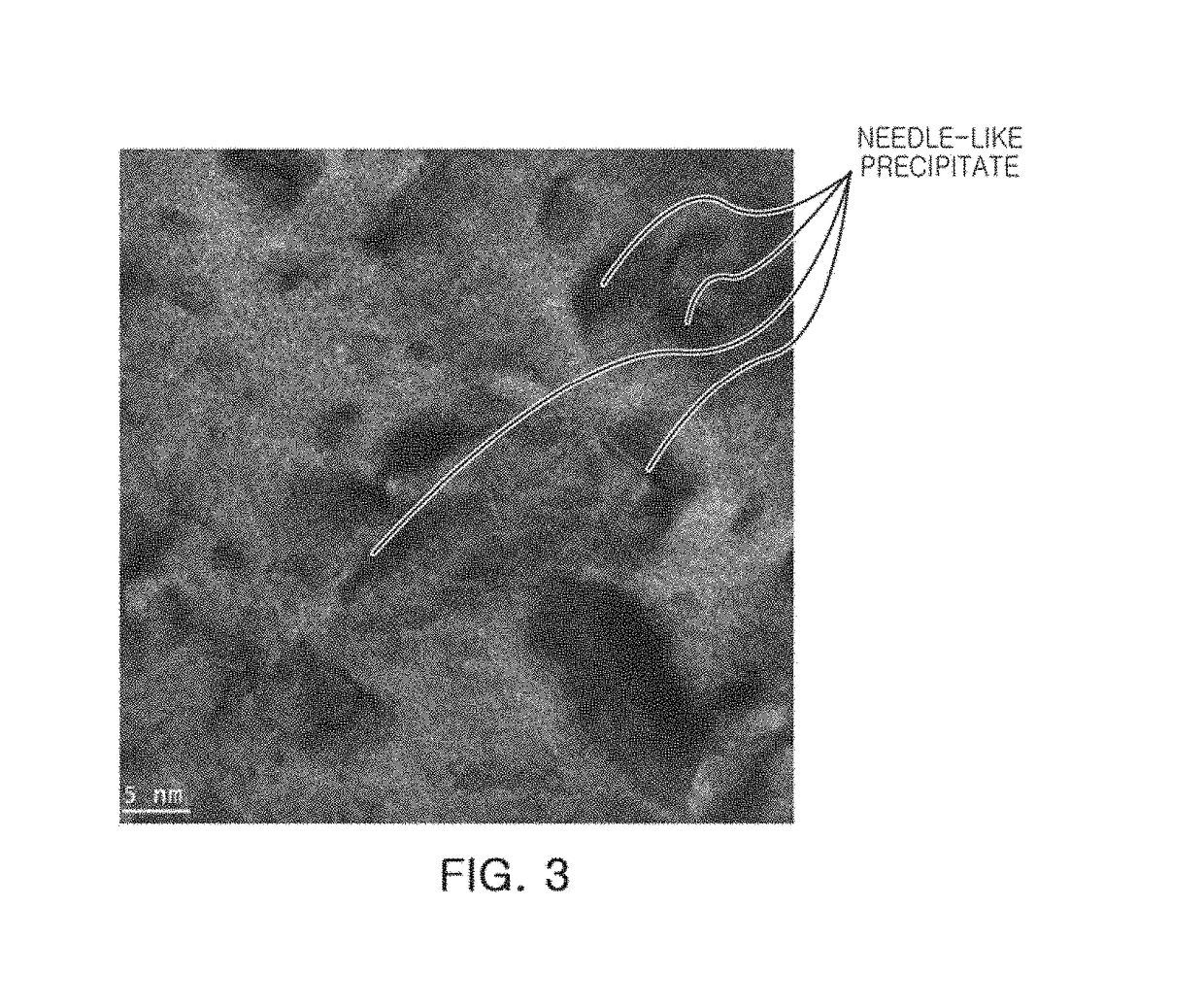

[0054]The alloy, having been cooled after the homogenization heat treating, is rolled downed to the thickness of 1 mm, heat treated at 430° C. for 10 hours, so a precipitate was formed.

[0055]Meanwhile, regarding the high-entropy alloy having been manufactured as described above, a sheet having a thickness of 1 mm was tensile-tested, and mechanical properties were evaluated, which are illustrated in Table 1.

TABLE 1TensileYieldstrengthstrengthElongationDivisionAlloyPrecipitate form(MPa)(MPa)(%)ComparativeCo20Cr20Fe20Mn20Ni20—6204...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com