High-strength steel plate and manufacturing method thereof

A high-strength steel plate and manufacturing method technology, applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve the problem that the processability is not comparable to that of polygonal ferrite, it is difficult to achieve high strength and processability at the same time, and the processability cannot be obtained And other problems, to achieve the effect of excellent extension flange, excellent ductility, and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

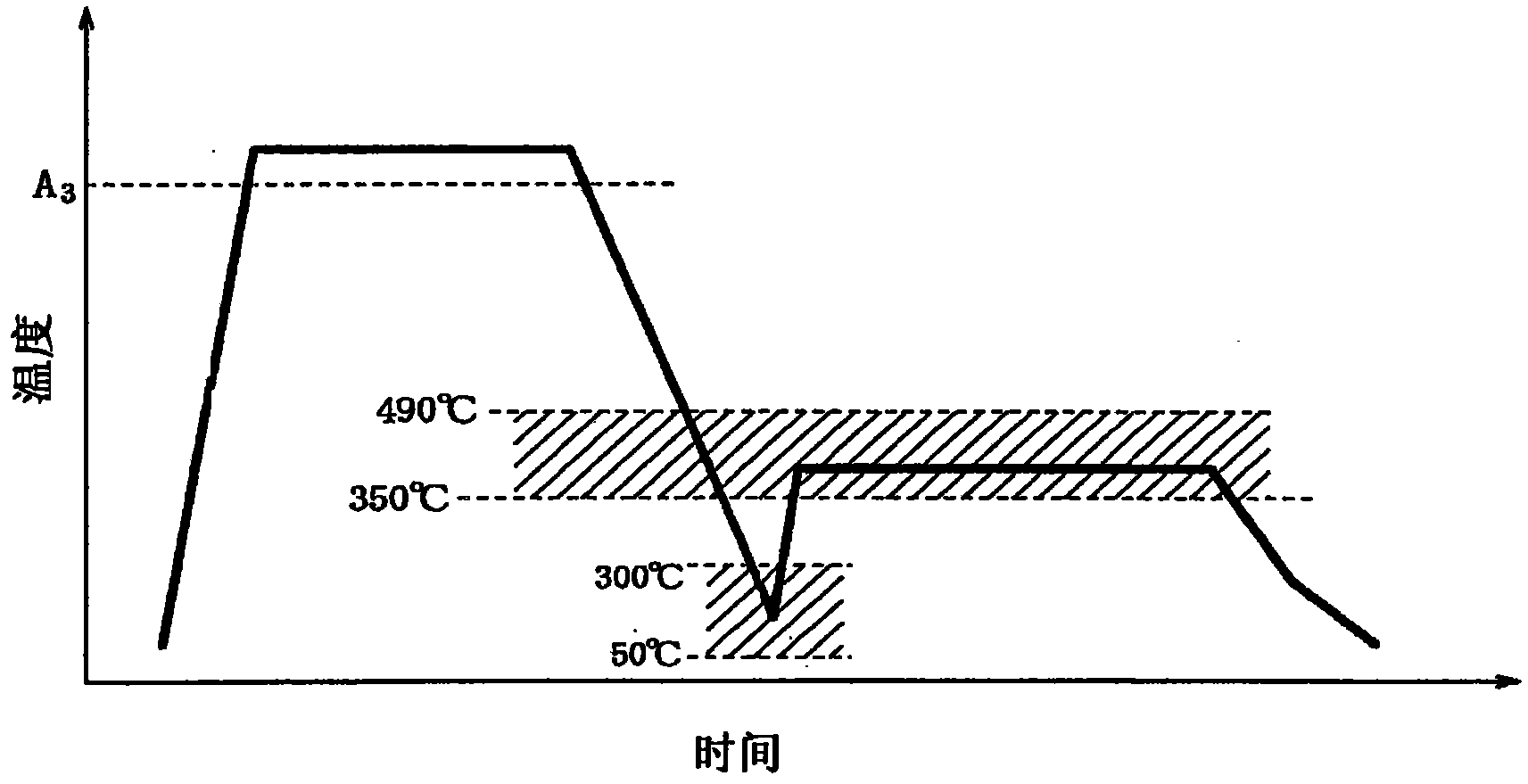

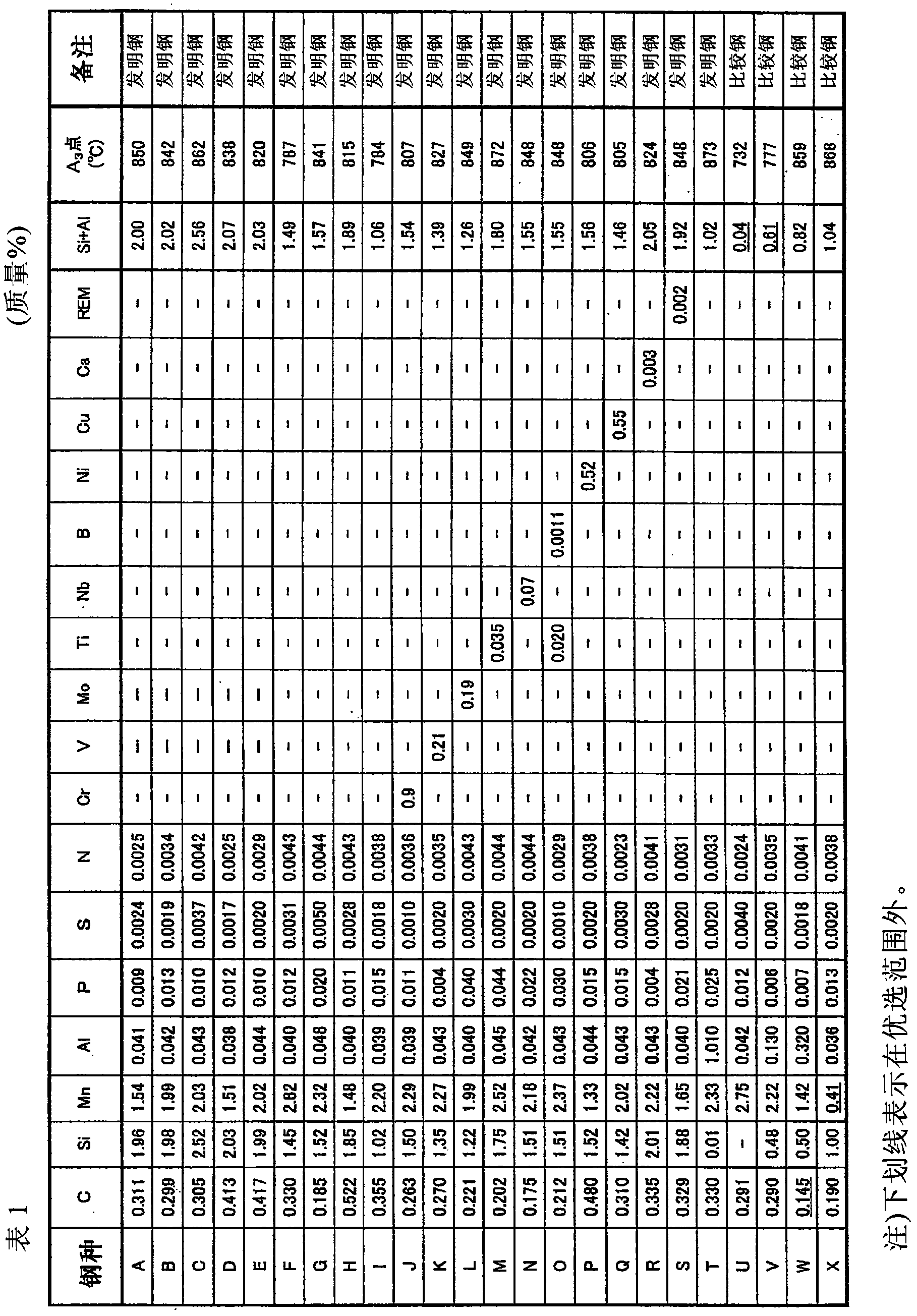

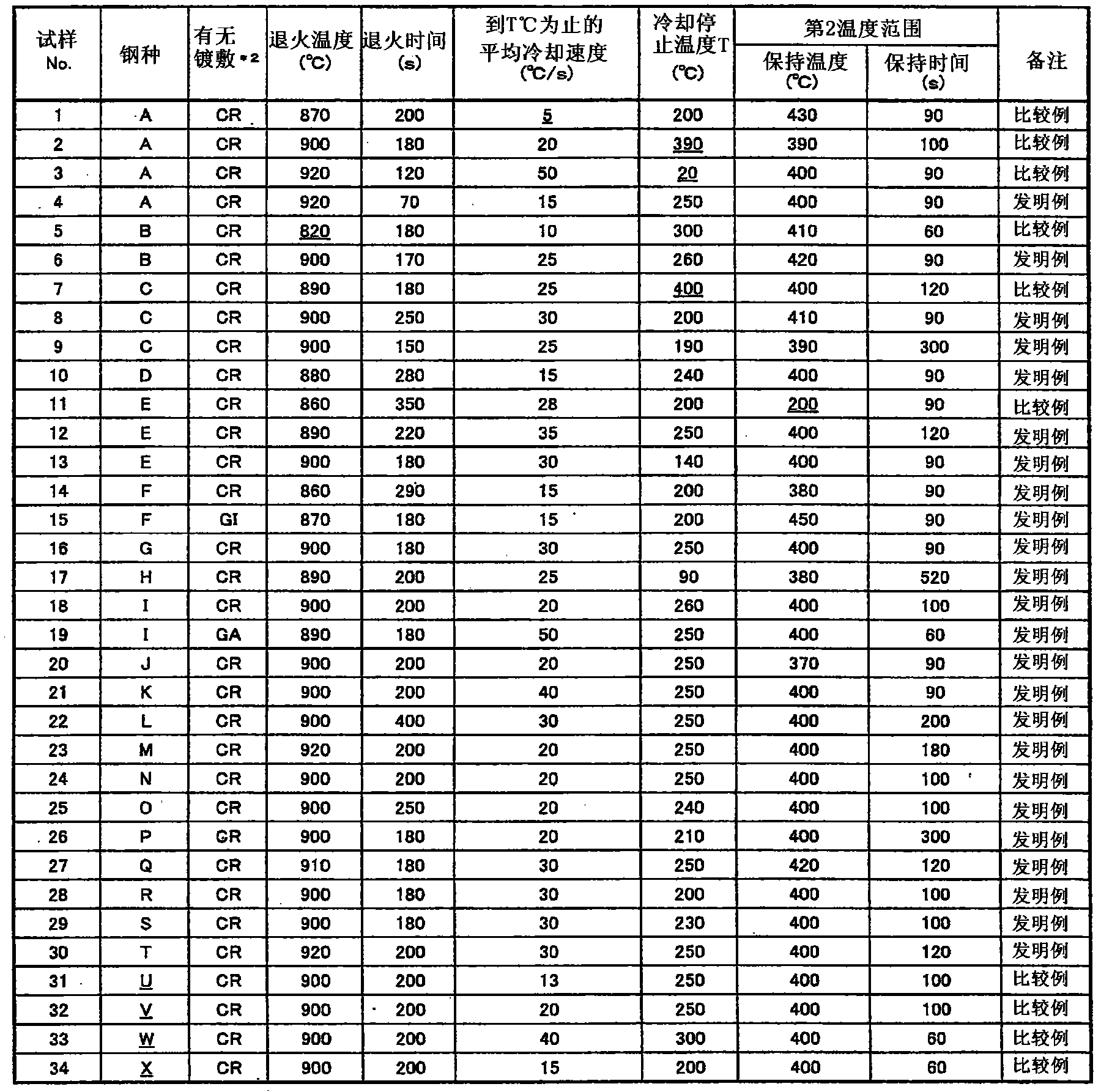

[0124] Steel slabs obtained by smelting steel with the composition shown in Table 1 were heated to 1200°C, then hot-finished at 870°C, and the resulting hot-rolled steel sheets were coiled at 650°C, and then the hot-rolled steel sheets were pickled Thereafter, cold rolling was performed at a rolling reduction (rolling ratio) of 65% to obtain a cold-rolled steel sheet having a thickness of 1.2 mm. The obtained cold-rolled steel sheets were heat-treated under the conditions shown in Table 2.

[0125] The cooling stop temperature T in Table 2 refers to the temperature at which the cooling of the steel sheet is stopped when the steel sheet is cooled from the annealing temperature.

[0126] In addition, hot-dip galvanizing treatment or alloying hot-dip galvanizing treatment is performed on a part of the cold-rolled steel sheet. Among them, the hot-dip galvanizing treatment is based on a coating bath temperature of 463°C and an adhesion amount (single surface) of 50g / m 2 condition...

Embodiment 2

[0152] Steel slabs obtained by smelting steel types a, b, c, d, and e shown in Table 4 were heated to 1200°C, then finished rolling at 870°C, and the resulting hot-rolled steel sheets were coiled at 650°C, followed by After the hot-rolled steel sheet was pickled, it was cold-rolled at a rolling reduction (rolling ratio) of 65% to obtain a cold-rolled steel sheet with a thickness of 1.2 mm. The obtained cold-rolled steel sheets were heat-treated under the conditions shown in Table 5. Then, the heat-treated steel sheet was subjected to temper rolling with a rolling ratio (elongation) of 0.5%. In addition, A in Table 4 3 The point is obtained by the above formula, and the Ms point in Table 5 is the martensitic transformation initiation temperature of each steel type measured by the Foamaster test. In addition, in Table 5, Inventive Example 1 is an inventive example in which the first temperature range (cooling stop temperature) is lower than Ms-100°C, and Inventive Example 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com