Rare earth treatment Low -cost high toughness Low -temperature pressure vessel steel plate and its production method

A pressure vessel, low-cost technology, applied in the field of rare earth treatment of low-cost high-toughness low-temperature pressure vessel steel plate and its production, can solve the problems of complex production process, high equipment requirements, high production cost, etc., to solve the problem of unstable performance and avoid aggregation Effect of growth and improvement of low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

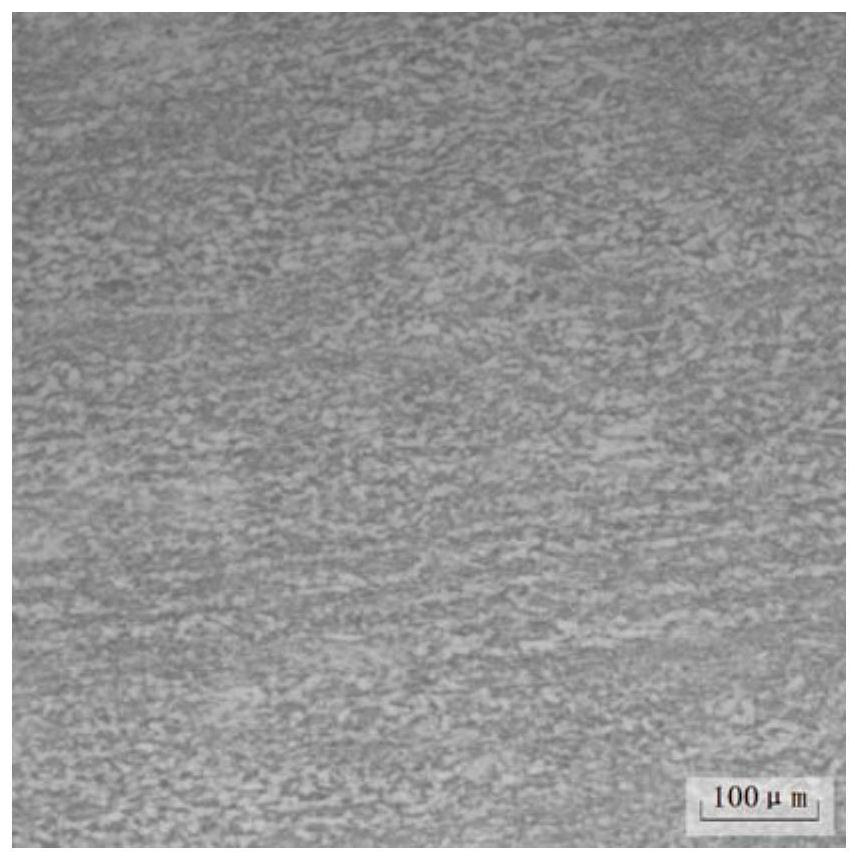

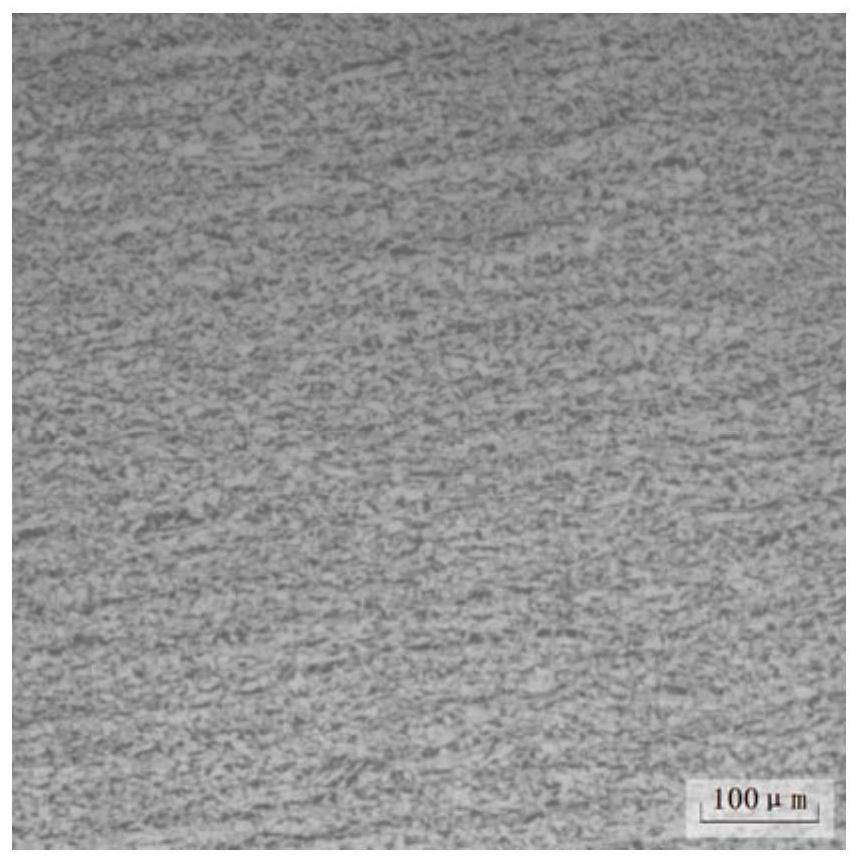

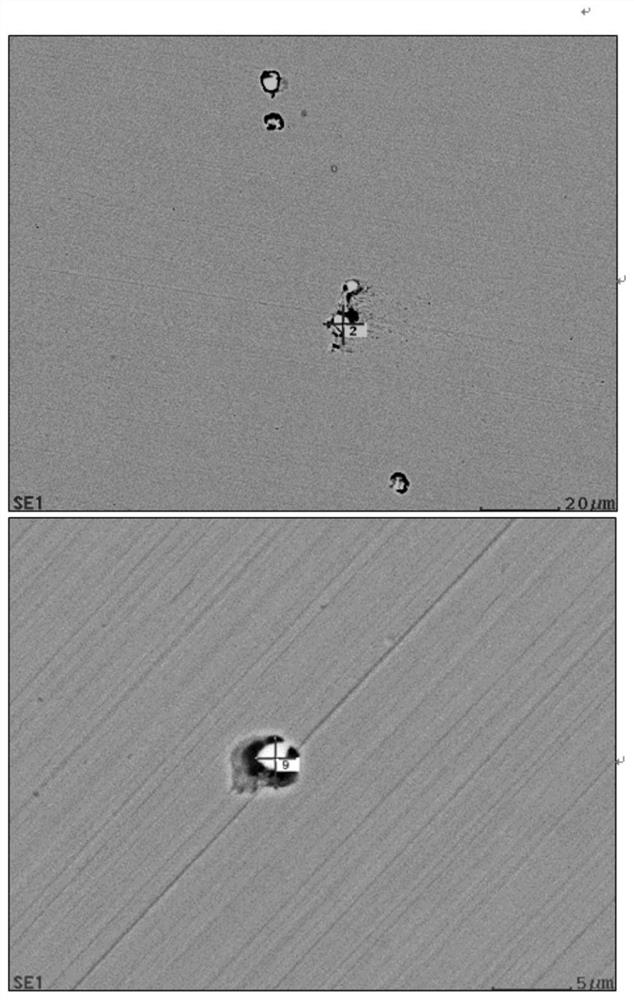

Image

Examples

Embodiment 1

[0034] The production method of low-cost, high-toughness, low-temperature pressure vessel steel plate treated with rare earth includes the following steps:

[0035] 1) Converter smelting. Oxygen smelting with top and bottom blowing is adopted, and the C content at the end point is controlled to be 0.04%, S≤0.020%, P≤0.015%, and the slag retaining ball is used for tapping. When the tapping reaches 1 / 4 and 1 / 2, according to batches Limestone and fluorite slag are added for washing, and the amount added in each batch is 1 / 2 of the total amount of slag, and aluminum alloy is added for deoxidation, requiring Als ≥ 0.020%;

[0036] 2) LF refining. In the early stage of refining, the composition is adjusted and the Nb and Ti are micro-alloyed. The present invention is a micro-alloyed steel. Nb and Ti are important micro-alloying elements, which form carbides and carbonitrides of Nb and Ti in the steel, which are steel the main toughness phase. At the same time, the oxygen content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com