Large-diameter zone-melting silicon single crystal growth method

A production method and a technology for a zone melting single crystal furnace, which are applied in the field of large-diameter zone melting silicon single crystal production, and can solve problems such as failure to achieve successful implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

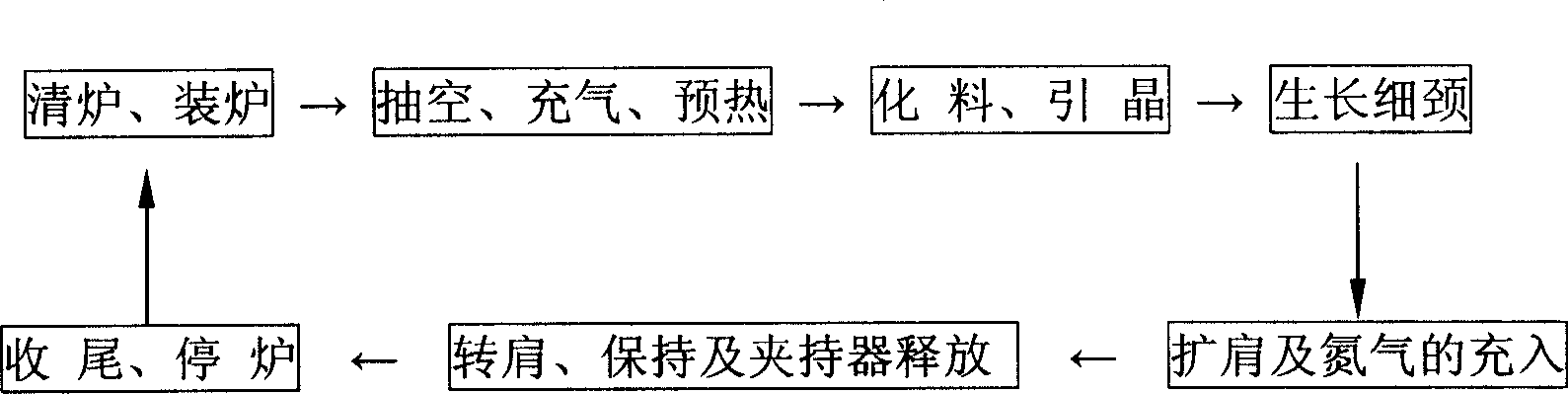

[0015] Refer to figure 1 .The process flow of melting silicon single crystal in large diameter zone is:

[0016] Furnace cleaning, furnace loading→evacuation, charging, preheating→materialization, seeding→growing necks→shoulder expansion and nitrogen filling→shoulder rotation, holding and release of holders→finishing and stopping the furnace.

[0017] (1) Furnace cleaning and furnace loading

[0018] Clean the entire furnace inner wall, heating coil, reflector, crystal holder, upper shaft, and lower shaft, adjust the level of heating coil and reflector, and align with the upper shaft and lower shaft.

[0019] Installation of polycrystalline materials:

[0020] ① Use scissors to cut open the plastic bag that packs the polycrystalline rods to expose only the grooves at the tail. Wear clean disposable plastic gloves, and fix the polycrystalline material clamp (crystal hanger) to the grooves at the tail of the polycrystalline rod. Place.

[0021] ②Insert the polycrystalline material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com