Preparation technology for monocrystal turbine guide vane

A turbine guide vane and preparation technology, which is applied in the field of superalloys, can solve the problems of difficult blade growth, serious composition segregation, and increased cost of single crystal blades, so as to avoid miscellaneous crystals and surface porosity, simple process method, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

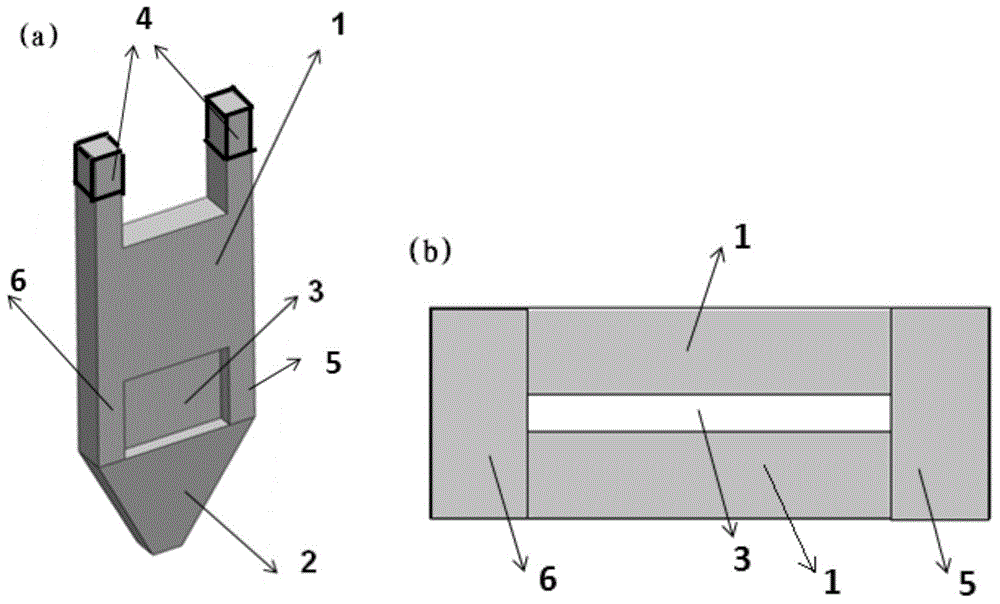

[0028] Firstly, the turbine blade wax mold, seed wafer wax mold 3 and single crystal crystal selector transition section wax mold 2 were prepared by injection molding, the injection temperature was 65°C, the pressure was 0.5MPa, the injection time was 10 seconds, and the pressure holding time was In 10 seconds, the thickness of seeding wafer wax mold 3 is 0.3 millimeters, the height of feeding segment 4 is 10 millimeters, and the length and width of its cross section are 5 millimeters; Then these three parts are pressed figure 1 Combine as shown, and then combine with the spiral crystal selector; the coating is powder (320 mesh) and silica sol solution, the powder is corundum powder, and the powder-to-liquid ratio is 3.5:1; the sanding material is corundum sand, the first layer of sanding 80-mesh sand, the second layer is 60-mesh sand, the third layer is 32-mesh sand, the fourth-seventh layer is 24-mesh sand, and the final sealing layer is made of surface coating; the wax mold ...

Embodiment 2

[0030] Firstly, the turbine blade wax mold, seed wafer wax mold 3 and single crystal crystal selector transition section wax mold 2 were prepared by injection molding. The injection temperature was 63°C, the pressure was 0.3MPa, the injection time was 30 seconds, and the pressure holding time was In 30 seconds, the thickness of seeding wafer wax mold 3 is 0.5 millimeters, the height of feeding segment 4 is 30 millimeters, and the length and width of its cross section are 20 millimeters; Then these three parts are pressed figure 1 Combine as shown, and then combine with the spiral crystal selector; the coating is powder (320 mesh) and silica sol solution, the powder is Shangdian powder, and the powder-to-liquid ratio is 3.2:1; the sanding material is Shangdian sand, and the sanding second The first layer is 80-mesh sand, the second layer is 60-mesh sand, the third layer is 32-mesh sand, the fourth-seventh layer is 24-mesh sand, and the final sealant layer is made of surface coat...

Embodiment 3

[0032] Firstly, the turbine blade wax mold, seed wafer wax mold 3 and single crystal crystal selector transition section wax mold 2 were prepared by injection molding, the injection temperature was 65°C, the pressure was 0.5MPa, the injection time was 10 seconds, and the holding time was 10 seconds; the thickness of seeding wafer wax mold 3 is 0.8 millimeter, the height of feeding section 4 is 20 millimeters, and the length and width of its cross section are 10 millimeters; Then these three parts are pressed figure 1Combine as shown, and then combine with the spiral crystal selector; the coating is made of powder (320 mesh) and silica sol solution, the powder is made of zircon powder, and the powder-to-liquid ratio is 3.5:1; the sanding material is zircon sand, and the sanding second The first layer is 80-mesh sand, the second layer is 60-mesh sand, the third layer is 32-mesh sand, the fourth-seventh layer is 24-mesh sand, and the final sealant layer is made of surface coating;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com