Polycrystalline synthesis and single-crystal growth method for germanium zinc phosphide

A technology of germanium zinc phosphide and growth method, applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of difficult to discharge impurities, low synthesis rate, etc., to ensure consistency, high synthesis rate, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

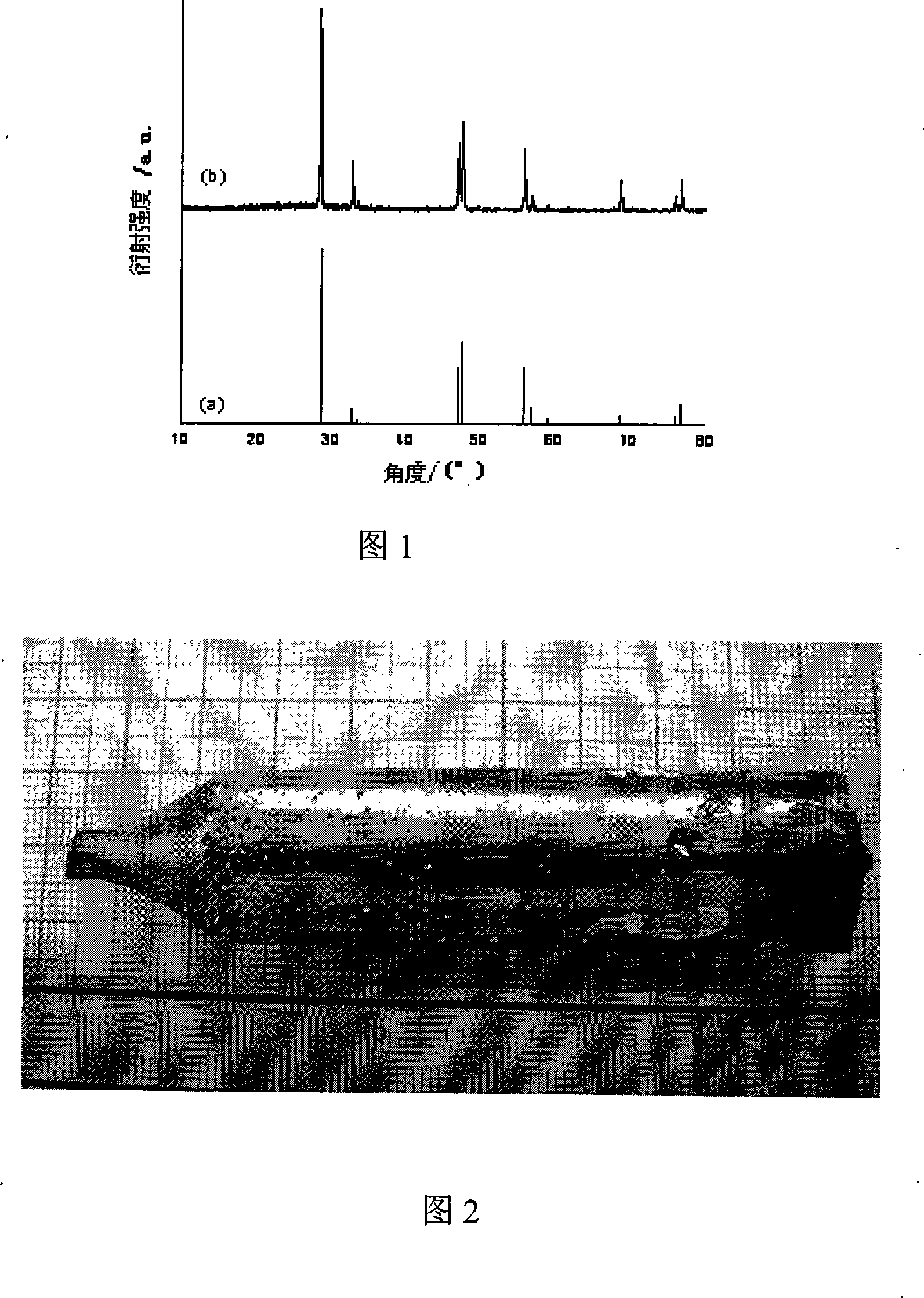

[0014] Specific embodiment one: the method for the polycrystalline synthesis of the zinc germanium phosphide of the present embodiment is carried out according to the following steps: one, select the zinc, germanium, phosphorus that the purity is more than 99.999% to be 1: 1: 2~2.005 by molar ratio The ratio is quantitative, put the reactants into the synthesis boat, place the synthesis boat in the quartz tube to vacuum seal, then put the quartz tube into the horizontal synthesis furnace, make the synthesis boat containing phosphorus in the low temperature area of the horizontal synthesis furnace, place The synthesis boat of zinc and germanium is located in the high-temperature zone of the horizontal synthesis furnace; 2. Raise the temperature so that the temperature in the low-temperature zone is 40-600°C, and the temperature in the high-temperature zone is 900-1080°C, keep the temperature for more than 3 hours, and then cool down to room temperature; that is, phosphating Ge...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 2, the temperature is raised so that the temperature in the low-temperature zone is 440-560° C., and the temperature in the high-temperature zone is 930-1050° C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 2, the temperature is raised so that the temperature in the low-temperature zone is 480-520°C, and the temperature in the high-temperature zone is 980-1000°C. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com