Growth process for N-type solar energy silicon single crystal with minority carrier service life of larger than or equal to 1,000 microseconds

A silicon single crystal, N-type technology, which is applied in the field of growing N-type silicon single crystals by the Czochralski method, can solve the problems of low service life of N-type Czochralski silicon single crystals, and achieve the effects of low cost, low service life and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Manufacture 6-inch single crystal according to the present invention

[0022] The present invention uses four-level bulk polysilicon (commercially available) for solar energy, phosphorus dopant (granular low-resistance phosphorus single crystal, low resistivity single crystal grown by Czochralski method, at room temperature, resistivity 0.001~0.005 Ω·cm). The resistivity measurement equipment is the HDY~4 four-probe tester produced by Guangzhou Semiconductor.

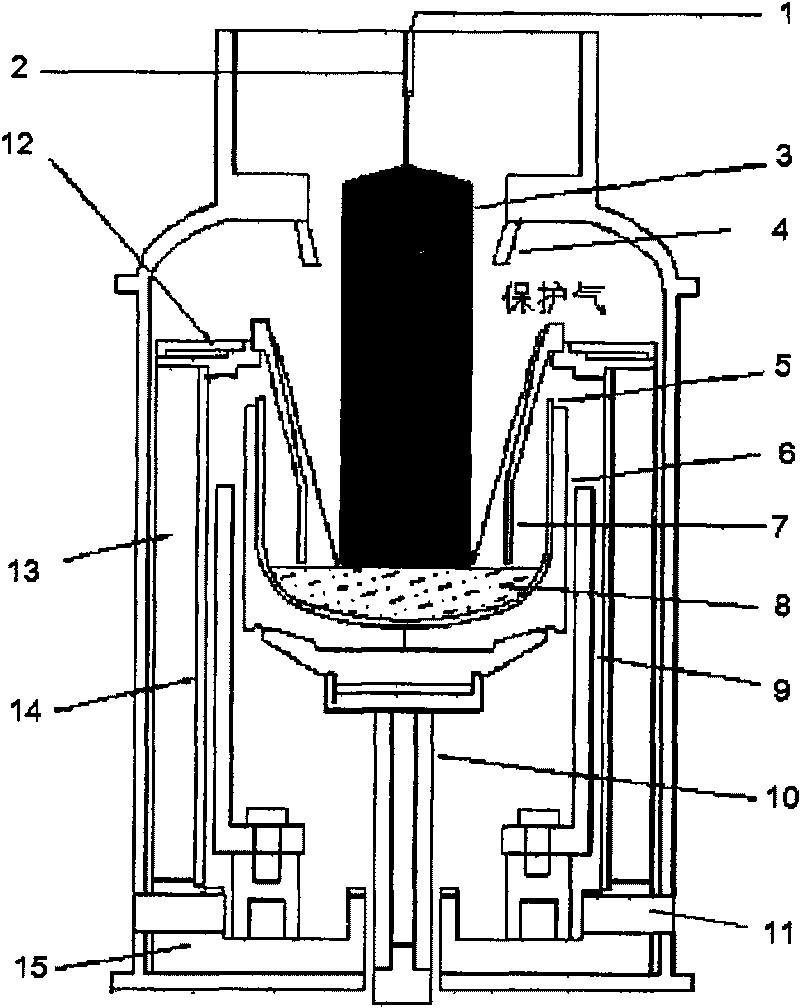

[0023] The structure of the monocrystalline silicon furnace that the present invention uses is as figure 1 As shown, 1~pulling; 2~seed crystal; 3~finished single crystal; 4~drain tube a; 5~quartz crucible; 6~graphite crucible; 7~drain tube b; 8~fused silicon; 9~ Heater; 10 ~ crucible rod; 11 ~ exhaust hole; 12 ~ upper cover; 13 ~ forming felt; 14 ~ heat preservation cylinder; 15 ~ heat preservation felt. Among them, 4 ~ guide tube a, 7 ~ guide tube b, 11 ~ exhaust holes are different from the disclosed convent...

Embodiment 2

[0035] The second example of representative experimental results: Φ8" single crystal was prepared under the same process conditions.

[0036] Φ8″ grown under a Φ20″ thermal field device with a feeding capacity of 90 kg, N-type crystal orientation, the resistivity of the silicon single crystal rod, the head ρ≤20Ω·cm, the tail ρ≥1Ω·cm. The interstitial oxygen content is [Oi]≤17.5ppma, the replacement carbon content is [Cs]≤0.5ppma, and the non-equilibrium minority carrier lifetime τ≥1000μs.

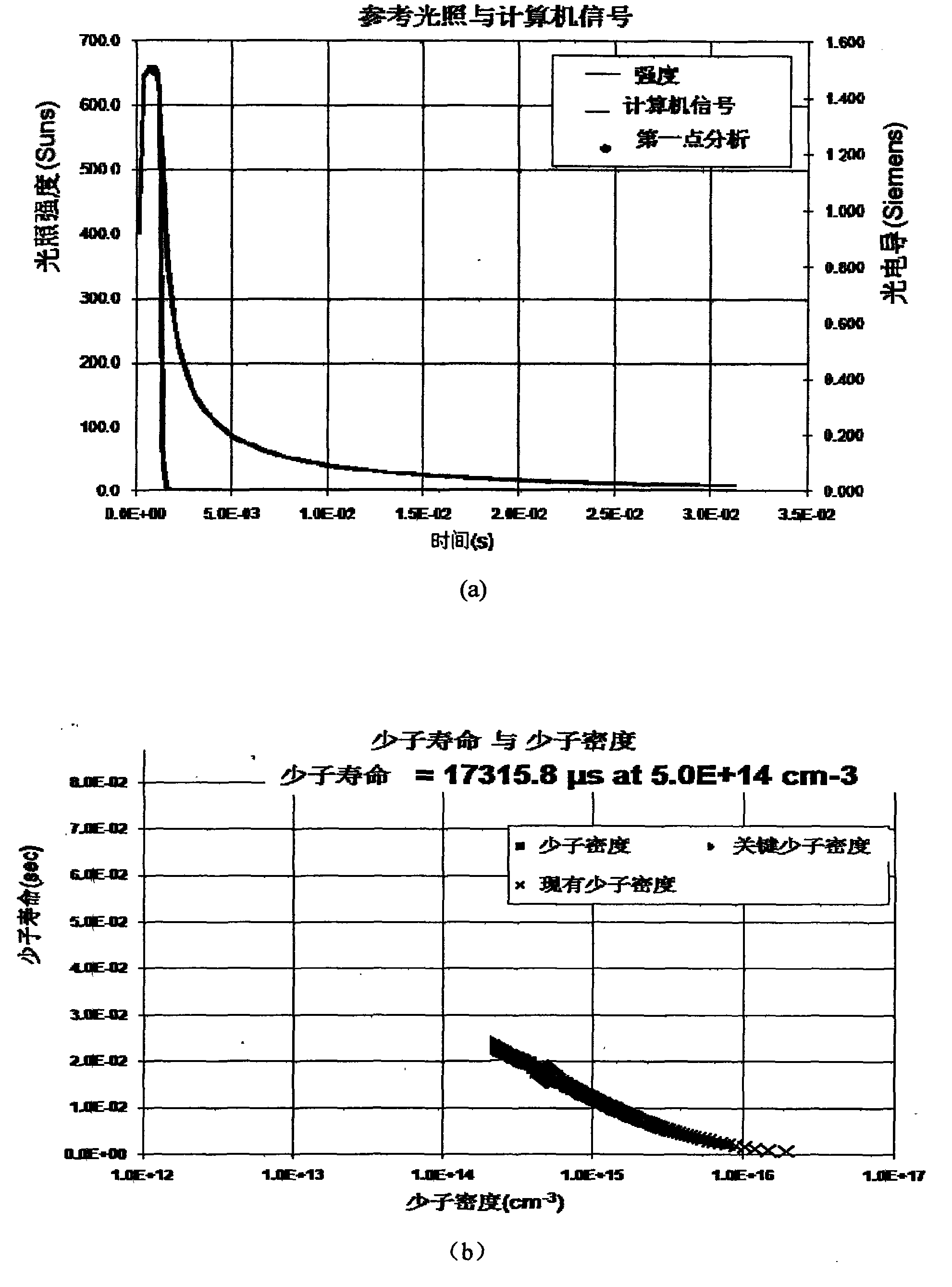

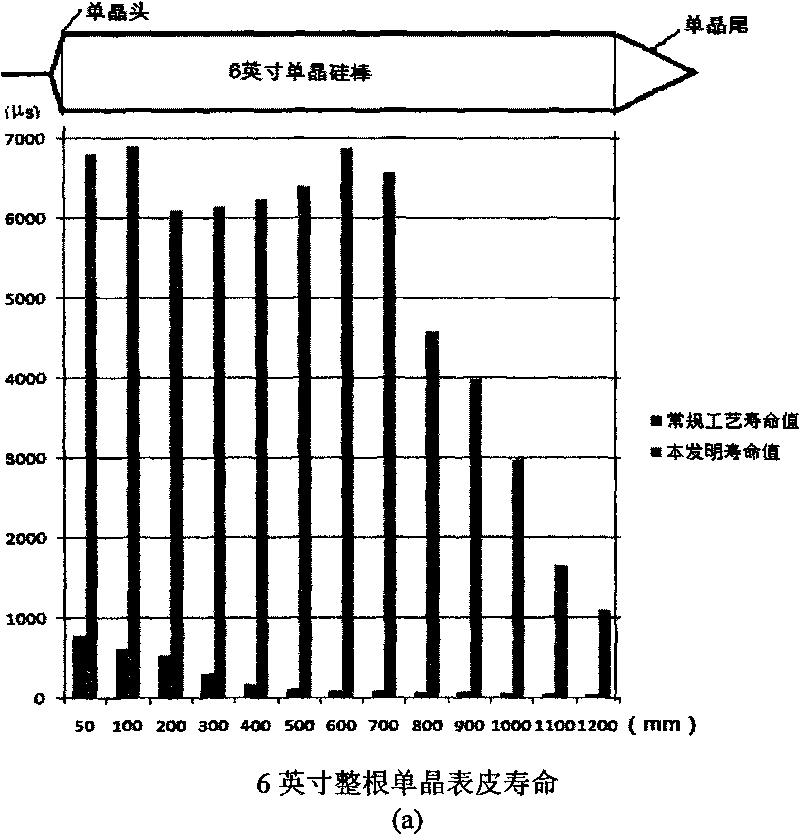

[0037] Minority life expectancy test results are as follows: figure 2 The shown (a) is the test condition of the minority carrier lifetime, (b) is the test result of the minority carrier lifetime; the life comparison of the Φ8″ single crystal obtained by the present invention and the conventional process (commonly used in the Czochralski silicon industry) is detailed in Figure 4 , (a) is the life comparison of the entire 8-inch single crystal skin, (b) is the center-to-edge life compari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| charge carrier lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com