Manufacturing method of liquid crystal phase shifter and liquid crystal phase shifter

A manufacturing method and a phase shifter technology, applied in the field of electronics, can solve the problem of low lifespan of liquid crystal phase shifters, and achieve the effect of improving the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

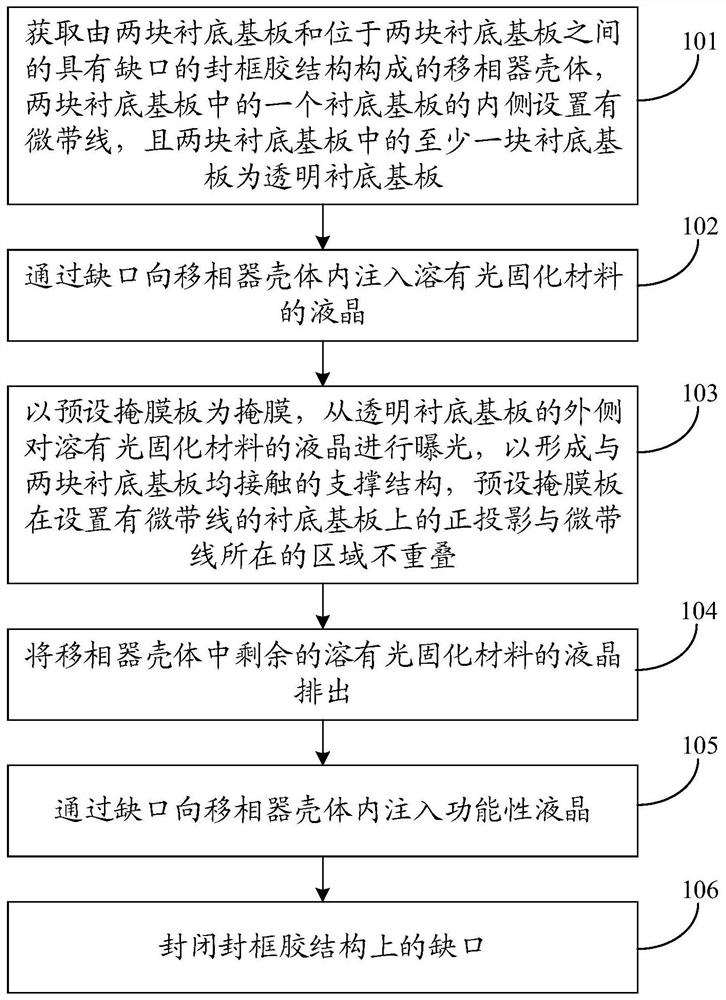

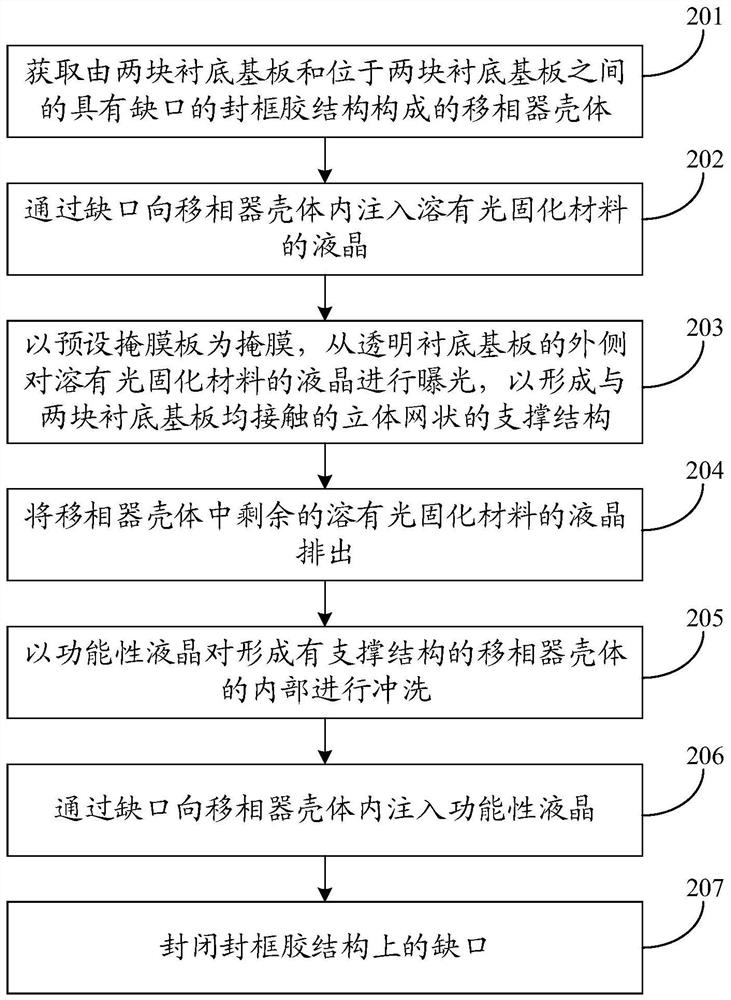

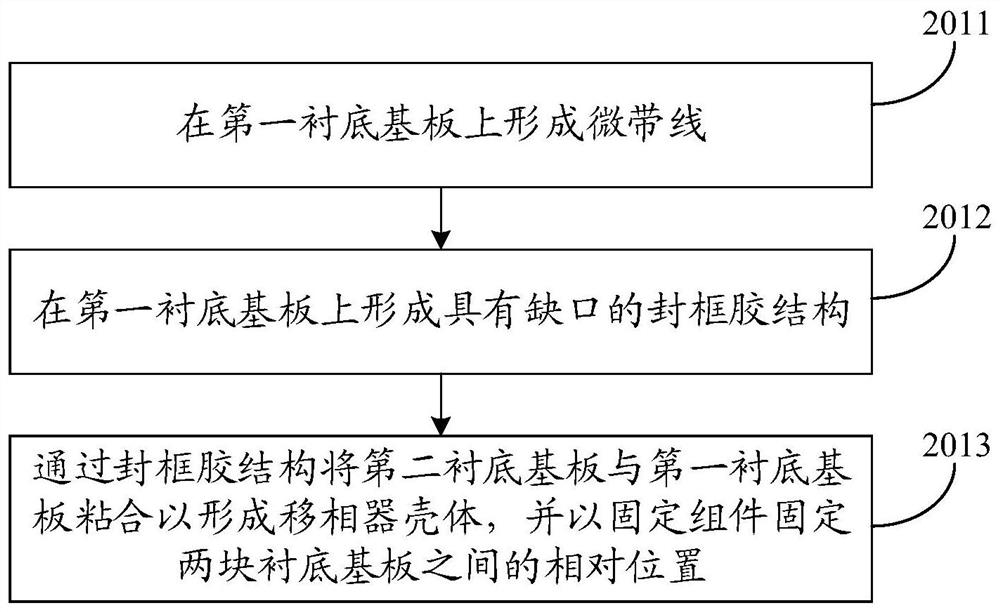

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0050] In the related art, the cell thickness of the liquid crystal phase shifter is usually maintained by a sphere in the frame-sealing glue structure. However, the sphere can only maintain the cell thickness at the edge of the liquid crystal phase shifter, and cannot do anything about the cell thickness of the region where the liquid crystal phase shifter is far from the edge.

[0051] If the sphere is placed inside the housing of the liquid crystal phase shifter, since it is difficult to fix the position of the sphere, the sphere may be located on the microstrip line, which will seriously affect the control of the liquid crystal by the microstrip line, thereby affecting the normal operation of the liquid crystal phase shifter .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com