Catalyst for Reducing Olefins from Reformate Aromatics with Long-period Operation

A technology for olefin catalysts and reformed oils, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, and hydrocarbon oil treatment. It can solve the problems of low service life of reformed oil de-olefin catalysts, and achieve short service life and reduce side reactions. , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Contains 3.0wt% LaO, 1.0wt% Na 2 USY of O (SiO 2 / Al 2 o 3 than 7.0), and 25.0wt% alumina catalyst 60.0g, using SnSO 4 Solution (containing Sn3.0wt%) 38g is impregnated with equal volume, after drying at 550°C and roasting for 3 hours, use Mg(NO 3 ) 2 35 g of the solution (containing Mg 1.0 wt %) was impregnated with equal volume, dried at 520° C. and calcined for 3.0 hours to obtain catalyst A.

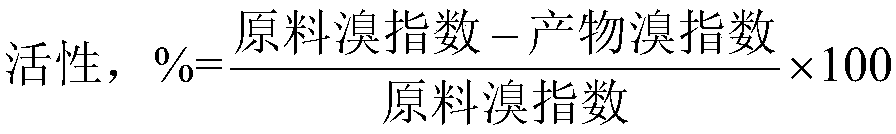

[0031] Get 3.0g catalyst and carried out reformed oil non-hydrogenation deolefin test in fixed-bed reactor, raw material is reformed oil, bromine index is 1200 mg Br / 100 gram oil (this reaction raw material evaluation that all following embodiments adopt) . The activity calculation formula is as follows:

[0032]

[0033] Reaction pressure: 2.0MPa, temperature: 160°C, space velocity: 10.0 hours -1 , the activity result was 95% in 2 hours, 90.5% in 100 hours, and 82.0% in 200 hours.

Embodiment 2

[0035] Contains 2.0wt% LaO and 2.0wt% CeO 2 , 0.5wt%Na 2 USY of O (SiO 2 / Al 2 o 3 than 12.0), and 25.0wt% alumina catalyst 60.0g, using Ga(NO 3 ) 3Solution (containing Ga 1.5wt%) 40g is impregnated with equal volume, dried at 500°C and calcined for 4 hours, using Ca(NO 3 ) 2 36 g of the solution (containing 0.5 wt % of Ca) was impregnated with an equal volume, dried at 550° C. and calcined for 2.5 hours to obtain catalyst B.

[0036] Take 3.0g of catalyst and carry out reformate non-hydrogenation deolefin test in fixed bed reactor, reaction pressure: 5.0MPa, temperature: 180℃, space velocity: 8.0 hours -1 , the activity results were 95.0% in 2 hours, 88.0% in 100 hours, and 80.1% in 200 hours.

Embodiment 3

[0038] Contains 2.0wt% LaO and 2.0wt% CeO 2 , 0.5wt%Na 2 USY of O (SiO 2 / Al 2 o 3 ratio 12.0), and 60.0g of catalyst 10.0wt% of alumina, using Ga(NO 3 ) 3 Solution (containing Ga 1.5wt%) 40g is impregnated with equal volume, dried at 500°C and calcined for 4 hours, using Ca(NO 3 ) 2 36 g of the solution (containing 0.5 wt % of Ca) was impregnated with an equal volume, dried at 600° C. and calcined for 2.0 hours to obtain catalyst C.

[0039] 3.0g of catalyst was taken in a fixed bed reactor to carry out reformate non-hydrogenation deolefin test, reaction pressure: 3.0MPa, temperature: 170°C, space velocity: 5.0 hours -1 , the activity results were 96.0% in 2 hours, 92.0.0% in 100 hours, and 89.0% in 200 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com