Resin-based diamond grinding wheel for grinding semiconductor plastic package body and manufacturing method of resin-based diamond grinding wheel

A manufacturing method and technology of plastic encapsulation, applied in the direction of manufacturing tools, abrasives, grinding devices, etc., can solve the problems of low grinding wheel life and poor surface finish of products, and achieve the effect of improving the yield rate and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific content of the present invention will be further explained in detail below in conjunction with the examples.

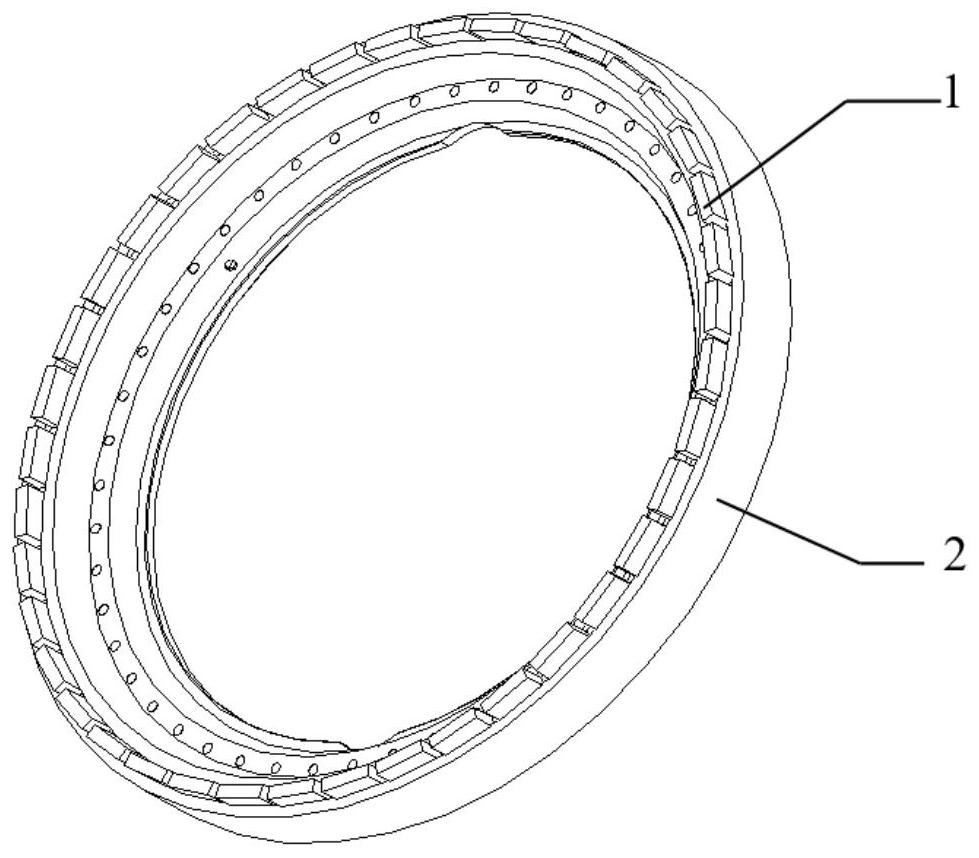

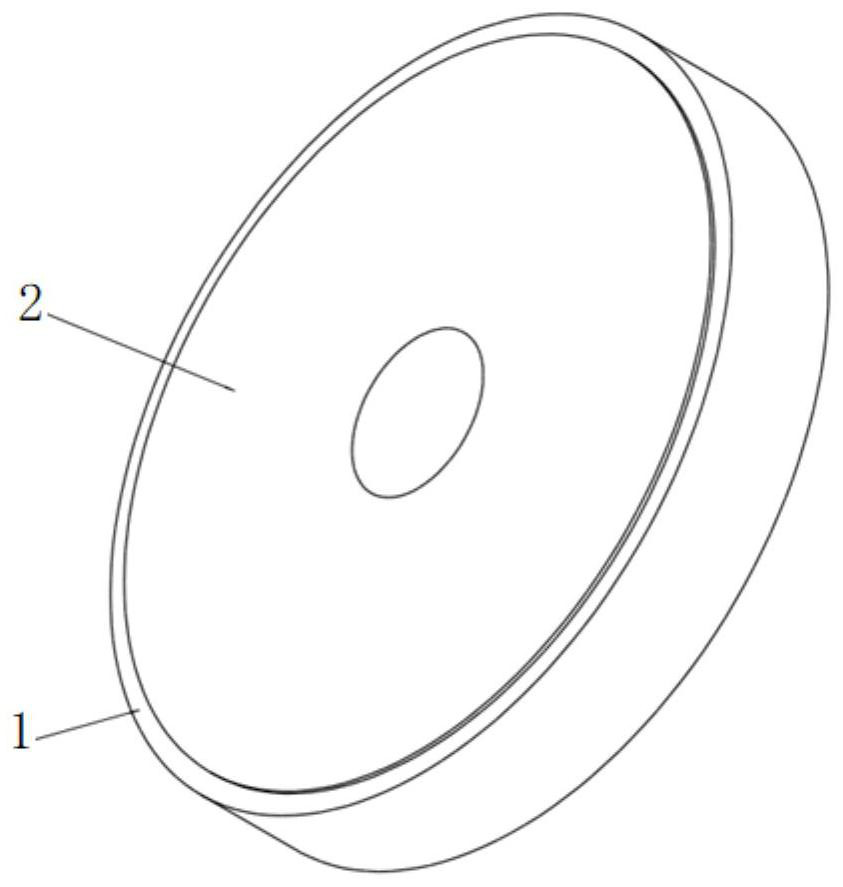

[0041] A resin-based diamond grinding wheel for grinding a semiconductor plastic package according to the present invention is composed of an aluminum alloy substrate and a grinding block bonded to the aluminum alloy substrate;

[0042] The grinding block is obtained by mixing and pressing molding with mass percentages of 40-50% resin binder, 45-50% diamond powder and 5-10% auxiliary agent;

[0043] Wherein, the particle size of the resin binder is 10-50 μm, and the resin binder includes 40-50% brominated epoxy resin, 40-45% polyvinyl acetal modified phenolic resin, 5-10% alumina and 5% by mass percentage. -10% silicon carbide;

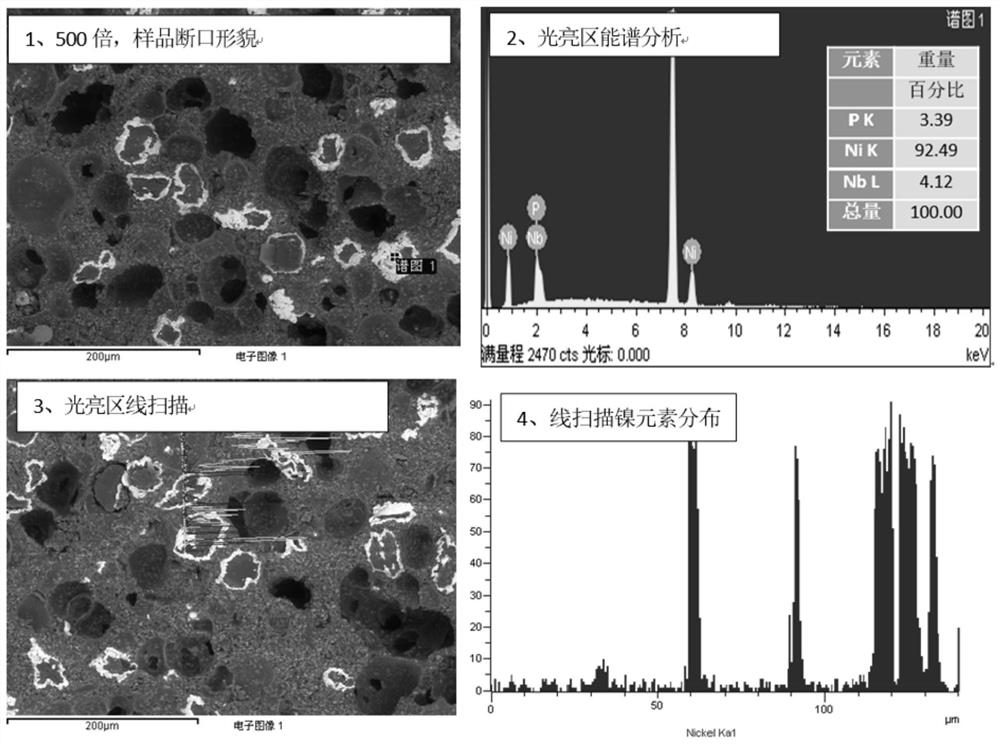

[0044] The diamond powder is sieved polycrystalline diamond powder with a particle size of 5-50 μm, and the surface of the polycrystalline diamond powder is metallized and plated with Ni, Ti or Co elements. The auxiliary a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com