Rotary magnetic field generating device for welding and working method thereof

A technology of generating device and rotating magnetic field, applied in welding accessories and other directions, can solve the problems of unsatisfactory welding quality, component segregation, uneven heat distribution, etc., to improve heat distribution, increase component subcooling, and structural layout. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

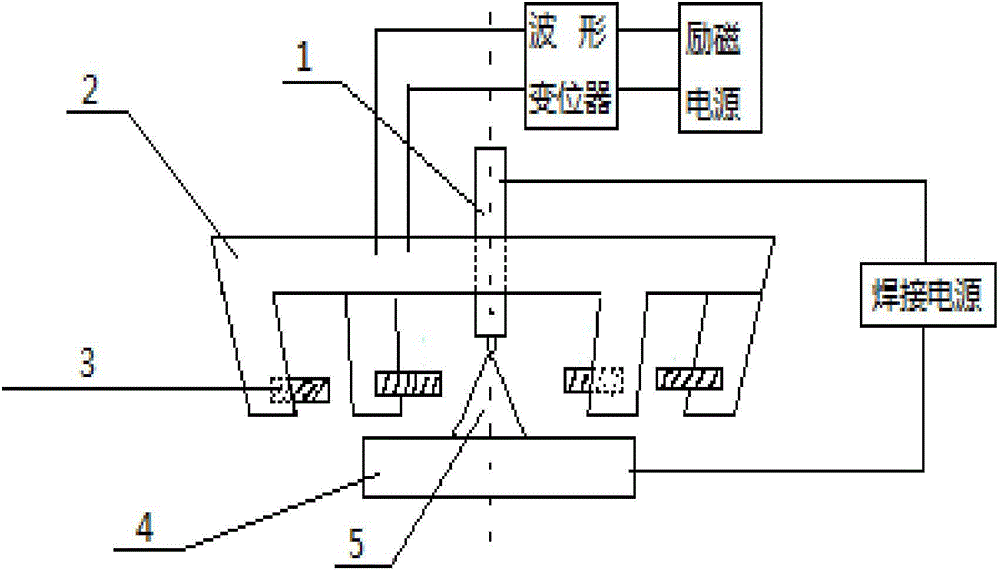

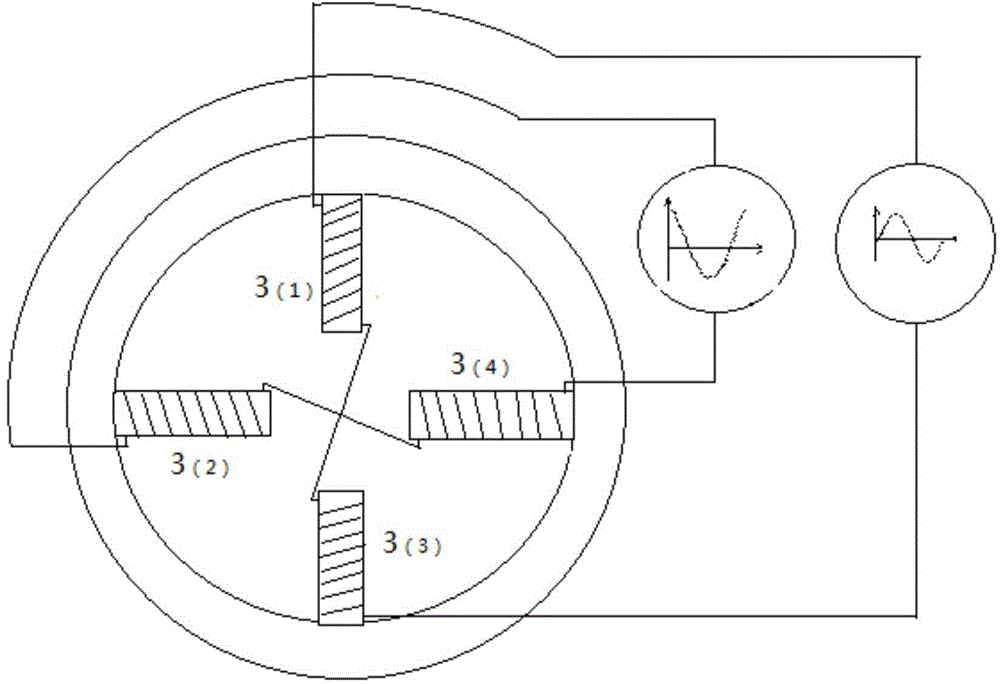

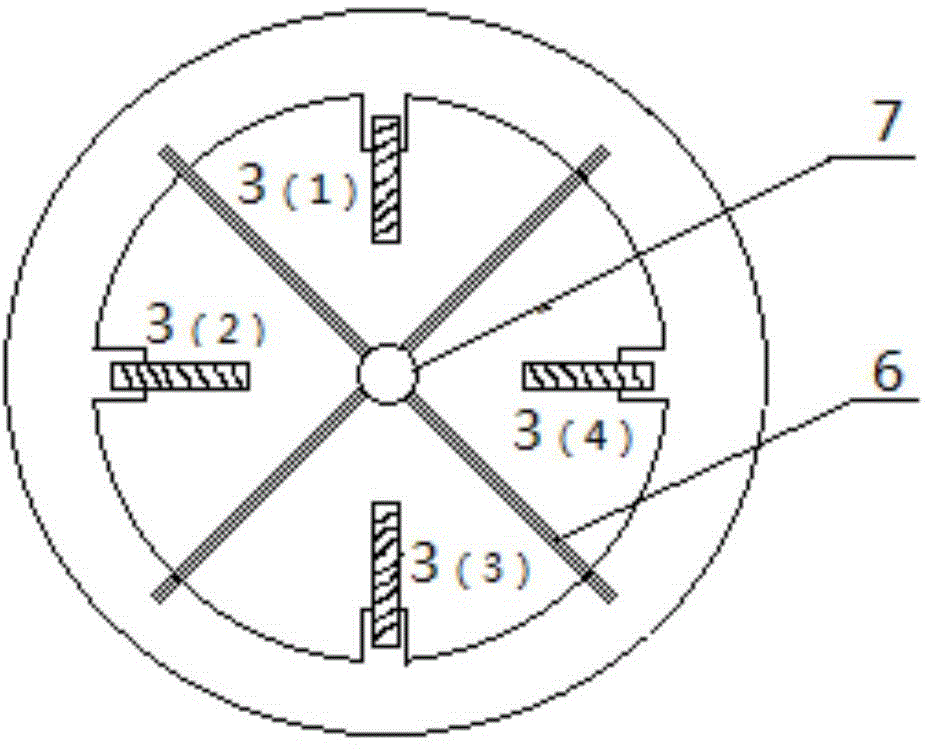

[0018] see Figure 1-Figure 4 , to make a circular platform-shaped barrel wall of appropriate size, with no bottom up and down, and the small bottom facing down, and four appropriate wide brackets are left at the cross-symmetrical positions of the center of the bottom to fix the excitation coil. The four coils are of the same height, and the central axis is facing the center of the circle, and they are divided into two groups with two facing each other as a group. Two symmetrical brackets are installed on the upper part of the big end of the barrel wall, and the center part of the middle circle is used to fix it on the welding torch. The above two groups of coils are respectively connected to the excitation power supply through a waveform shifter, and adjusted so that the two groups of coils are respectively connected to synchronous sine alternating current and cosine alternating current. After electrification, a magnetic field parallel to the coil axis is generated in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com