Method and device for controlling nickel-based high-temperature alloy brittle phase during laser additive manufacturing

A nickel-based superalloy and laser additive technology, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement, can solve the problem that the precipitation of the brittle phase of LAVES between dendrites cannot be reduced, and achieve the promotion of effective precipitation and increase the temperature Gradient, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

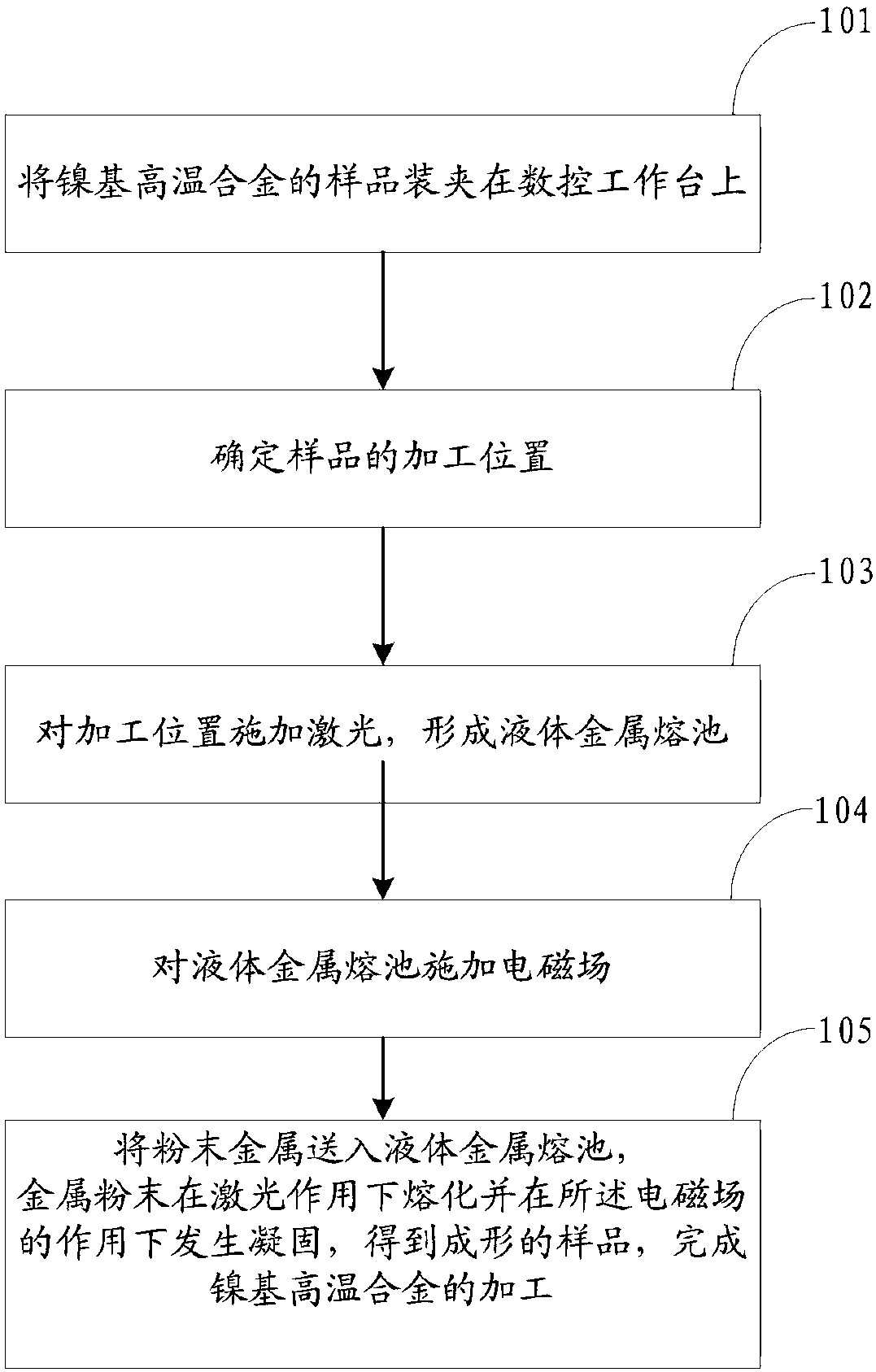

[0058] figure 2 It is the microstructure diagram of the nickel-based superalloy obtained by adopting the traditional coaxial powder feeding laser additive manufacturing method according to the embodiment of the present invention; image 3 The microstructural diagram of the nickel-based superalloy obtained by using the coaxial powder feeding laser additive manufacturing method of the present invention for the embodiment of the present invention; see figure 2 and image 3 .

[0059] S1. The process test obtained the process parameters with good formability of laser additive manufacturing of nickel-based superalloy. The parameters include: laser power 2000W, scan rate 480mm / min, powder feeding rate 5g / min, powder feeding gas flow rate 6L / min, laser spot The size is 2mm, the overlap rate between channels is 40%, and the height between layers is 0.3mm. The substrate used is 1Cr18Ni9Ti stainless steel, the powder used is GH4169 alloy powder prepared by plasma rotating electrode...

Embodiment 2

[0065] S1. The process test obtained good process parameters for laser additive repair of nickel-based superalloys. The parameters include: laser power 1400W, scanning rate 360mm / min, powder feeding rate 5g / min, powder feeding gas flow rate 6L / min, laser spot size 3mm , The overlap rate between the roads is 25%, and the height between layers is 0.3mm. The repair sample material is GH4169 nickel-based superalloy block with V-shaped groove defects. The powder used is GH4169 alloy powder prepared by plasma rotating electrode method, and the particle size is 100 mesh.

[0066] S2. During the whole process of laser additive repair of nickel-based superalloy, an auxiliary electromagnetic field is applied to the liquid metal in the molten pool. The parameters are: magnetic field strength 80mT, magnetic field frequency 50HZ, until the forming is completed. During laser additive repair, the electromagnetic generating device is placed on the workbench, and the formed sample or part is p...

Embodiment 3

[0068] S1. The process test obtained the process parameters with good formability of laser additive manufacturing of nickel-based superalloy. The parameters include: laser power 2500W, scan rate 400mm / min, powder feeding rate 10g / min, powder feeding gas flow rate 8L / min, laser spot The size is 2.5mm, the overlapping rate between channels is 50%, and the height between layers is 0.2mm. The substrate used is 1Cr18Ni9Ti stainless steel, the powder used is GH4169 alloy powder prepared by plasma rotating electrode method, and the particle size is 100 mesh.

[0069] S2. During the whole process of laser additive manufacturing of nickel-based superalloys, an auxiliary electromagnetic field is applied to the liquid metal in the molten pool. The parameters are: magnetic field strength 80mT, magnetic field frequency 100HZ, until the forming is completed. During forming, the electromagnetic generating device and the powder feeding head follow up.

[0070] Each embodiment in this specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com