Titanium alloy structural part and laser melting deposition forming method thereof

A laser melting deposition, titanium alloy technology, applied in the field of additive manufacturing, can solve problems such as inability to divide into multiple small-sized structures, difficult performance consistency control, increased production and turnover cycles, etc., to avoid and serious cracking risks. , The effect of eliminating the risk of serious cracking and shortening the forming cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

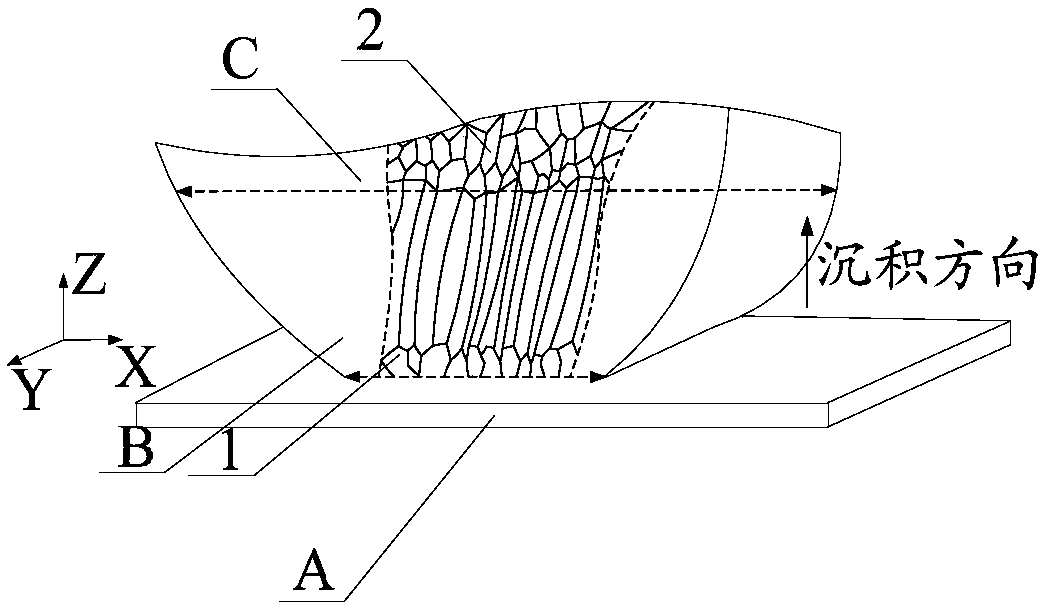

[0054] Such as figure 1 As shown, the present embodiment provides a titanium alloy structural member with a variable cross-section and special-shaped structure, the maximum dimension of which is 1500mm in one direction on the X-Y plane, and the maximum height (Z direction) is 1000mm, and its forming method includes:

[0055] Step 1: According to the size and structure of the titanium alloy structural part, determine the crack-prone area of the titanium alloy component, wherein the junction of the small end B of the titanium alloy structural part and the substrate A is the first crack-prone area 1, and the envelope Area C with a size ≥ 1000mm is the second easy-to-crack area 2;

[0056] Step 2: Use vacuum-dried TC11 titanium alloy powder with a particle size of 75-185 μm to obtain titanium alloy structural parts by laser melting deposition forming method, wherein:

[0057] Dry in the temperature range of 155°C for 3 hours during vacuum drying;

[0058] When forming the crac...

Embodiment 2

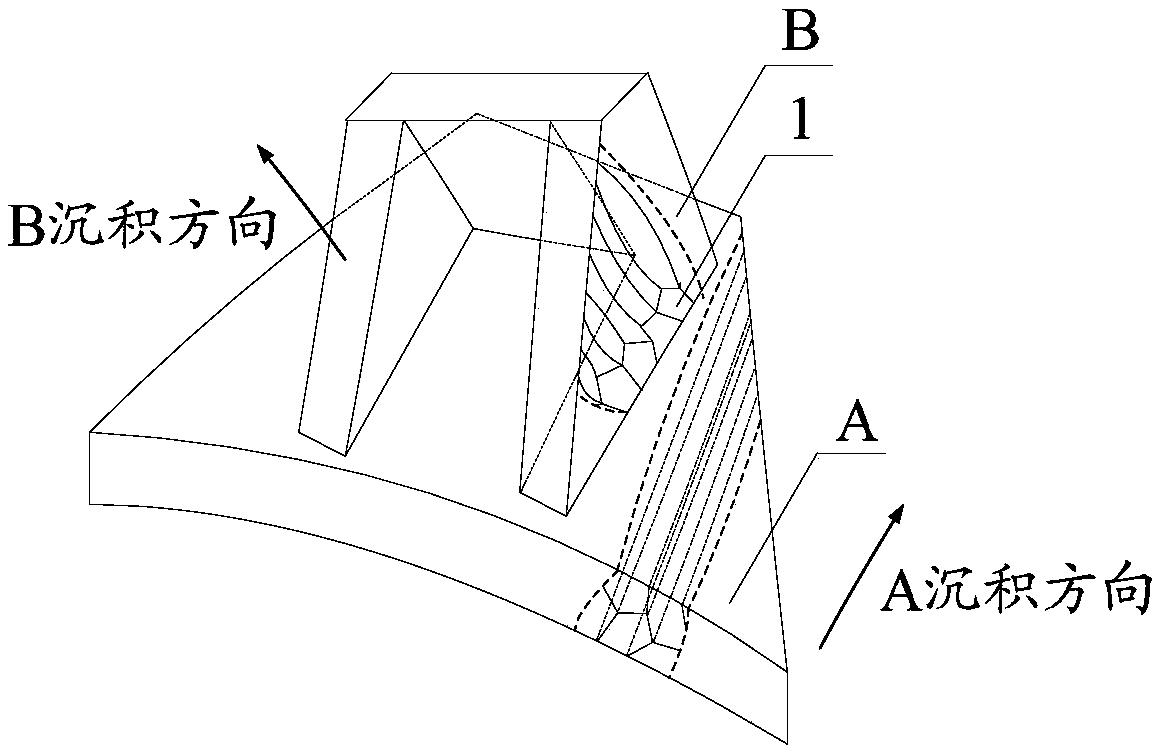

[0063] Such as figure 2 As shown, this embodiment provides a typical large-scale titanium alloy main load-bearing structure of a launch vehicle, which includes substructures A and B, the forming directions of substructure A and substructure B are perpendicular to each other, and substructure A is formed along the deposition direction of A The maximum size on the X-Y plane is 1500mm, and the maximum height (Z direction) is 1000mm. When the substructure B is formed along the B deposition direction, the maximum size on the X-Y plane is 600mm, and the maximum height (Z direction) is 300mm. The forming method includes :

[0064] Step 1: According to the size and structure of the titanium alloy structural part, determine the crack-prone area of the titanium alloy component, wherein the joint part of the substructure A and substructure B of the titanium alloy structural part is the first crack-prone area 1, which is is the boundary area between two different forming directions, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com