Thermal field system for sapphire single crystal growth

A sapphire and single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems affecting the stability of crystal growth, the difficulty of precise control of helium gas flow, and the consumption of large helium gas, so as to improve the quality , control accuracy and stability, and the effect of enhanced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

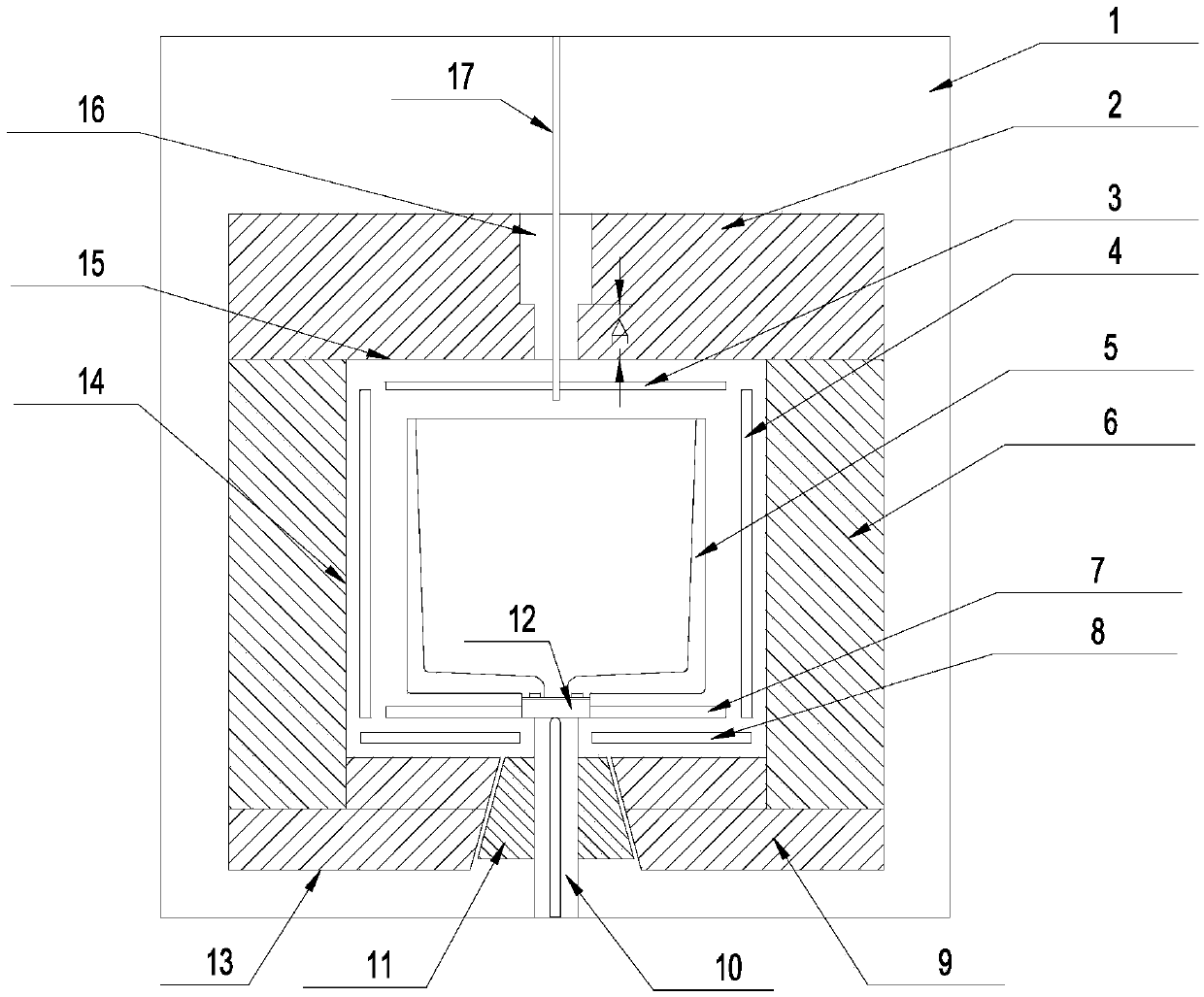

[0051] The thermal field system for sapphire single crystal growth of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0052] Such as figure 1 As shown, a thermal field system for sapphire single crystal growth includes: a furnace body 1 with a crucible 5 placement area inside, and heating devices and insulation layers arranged in sequence around the crucible 5 placement area from inside to outside.

[0053] The heating device includes a lower heating device 8 located at the bottom of the crucible 5 placement area and a side heating device 4 surrounding the crucible 5 placement area. The heating device adopts a graphite heater made of isostatic graphite. The lower heating device 8 and the side heating device 4 are respectively controlled by independent voltage-stabilized power supplies.

[0054] The bottom of the furnace body 1 is pierced with a support column 10 for placing the crucible 5 , and a crucible base tray 12 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com