Method for repairing concrete crack with multi-cracking cement-based composite

A composite material and cement-based technology, which is applied in the field of repairing concrete cracks with multi-cracked cement-based composite materials, can solve the problems of easy formation of main cracks in the repair layer, single crack failure characteristics, stress concentration of the repair layer, etc., and achieve superior strain hardening characteristics , Improve the ability to disperse cracks, and the effect of uniform and fine surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Use a multi-cracked cement-based composite material to repair concrete cracks by setting an isolation layer around the cracks and casting in-situ.

[0041] The weight ratio of each component of the multi-slit cracked cement-based composite material is cement: water: sand: fly ash: silica fume: water reducer = 1: 1.58: 1.5: 2.0: 0.15: 0.02, and the volume is the total volume of the composite material 2 % of polyvinyl alcohol fiber, the maximum particle size of sand is 0.2mm; the cement type is PII42.5R, the fly ash is Class I fly ash, and the water reducer is polycarboxylate water reducer.

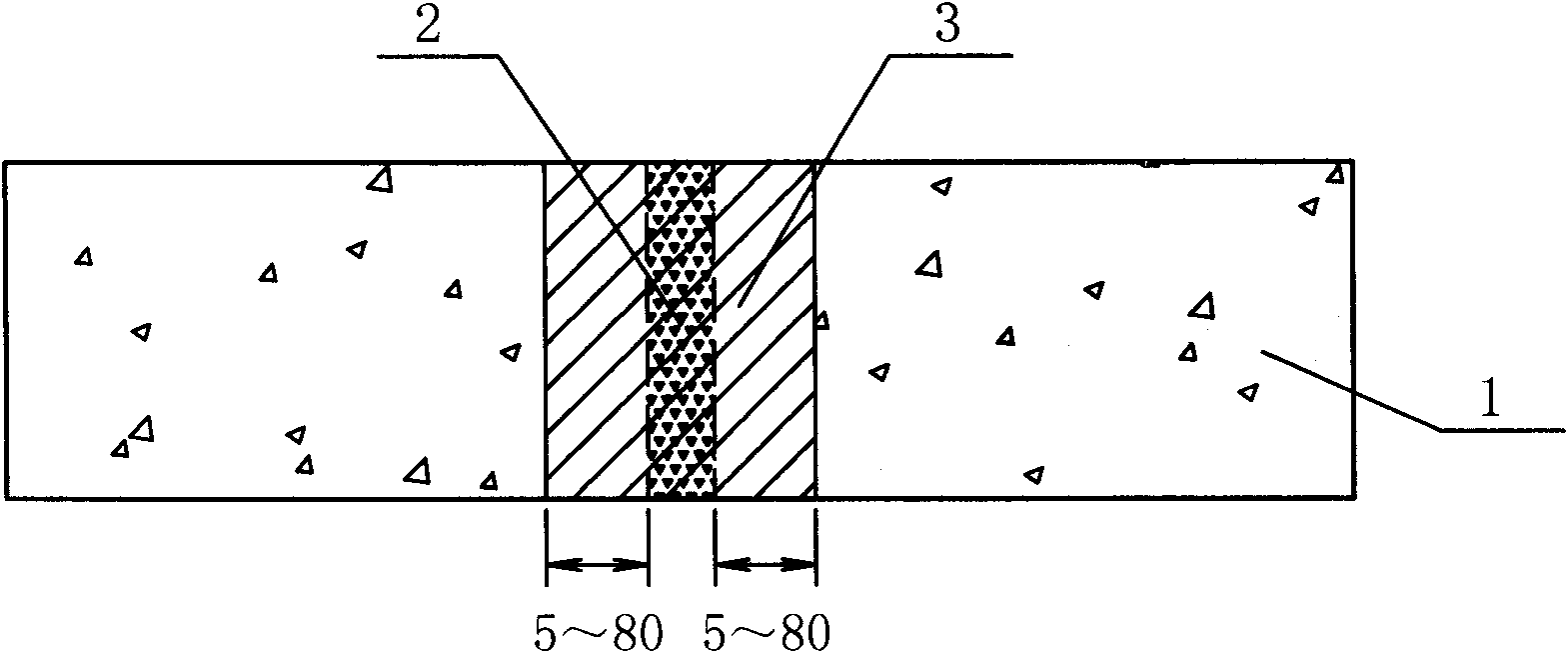

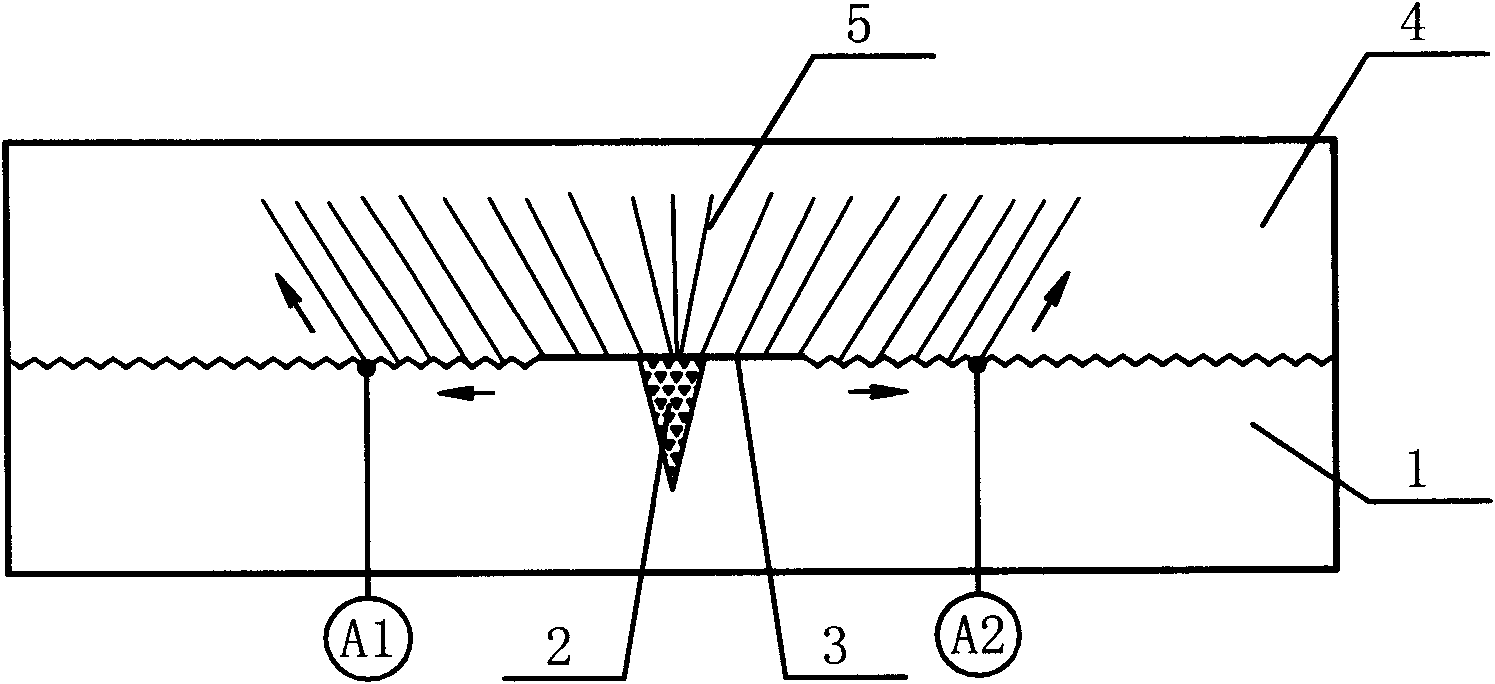

[0042] see figure 1 , figure 2 , The concrete structure adopts two separate prisms, and there is a precast concrete crack between the two concrete, and the crack length is 50mm. Remove floating dust on the concrete surface, clean the surface, and after the surface is slightly dry, paste waterproof tape on the outer 25mm area 3 around the concrete crack 2 (set an isolatio...

Embodiment 2

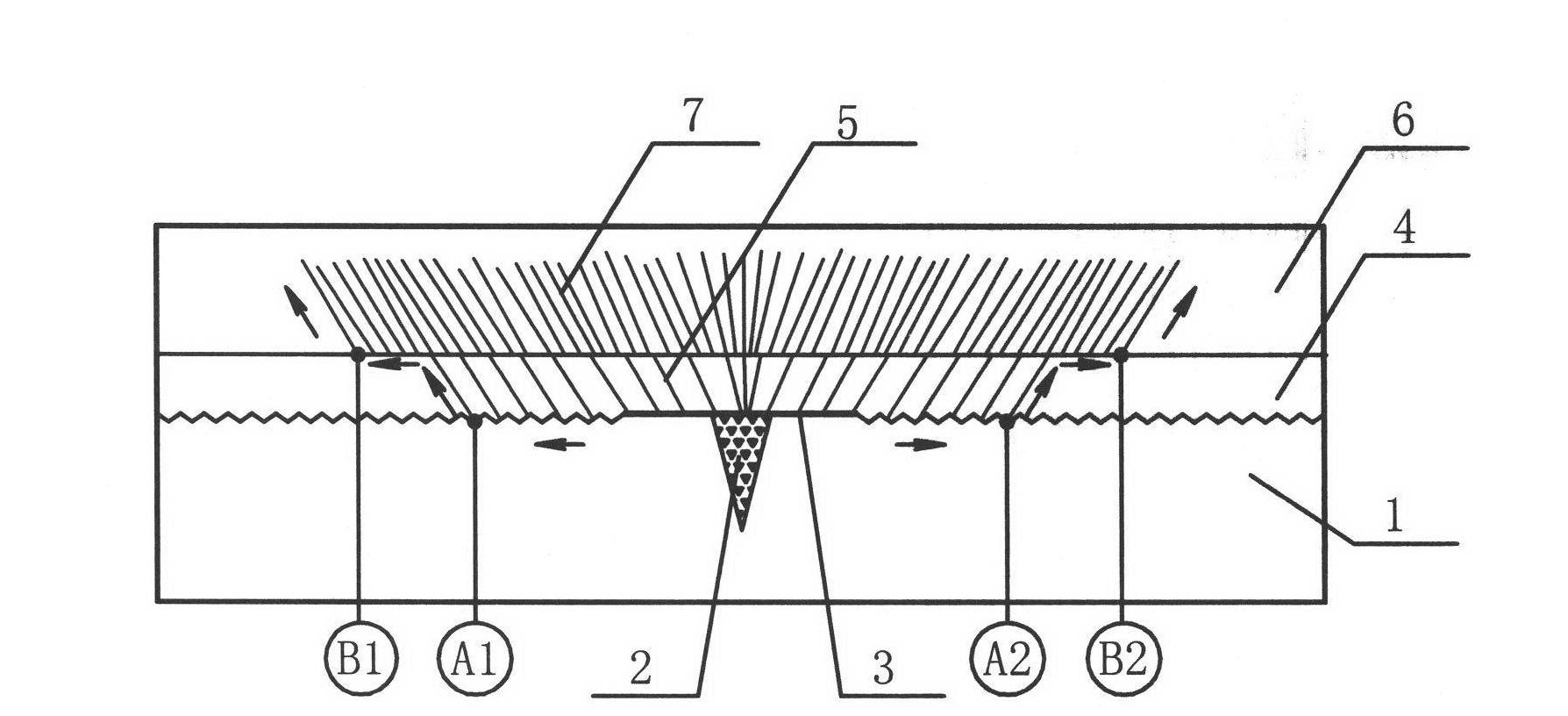

[0049] In Example 2, the cracks are repaired by setting an isolation layer around the cracks, first pouring a thin layer of multi-cracked cement-based composite material slurry, and then covering the prefabricated slabs.

[0050] The weight ratio of each component of the multi-slit cracked cement-based composite material is cement: water: sand: fly ash: silica fume: water reducing agent = 1: 1.23: 1.2: 1.8: 0.12: 0.01, and the volume contained is the total volume of the composite material 2% polyvinyl alcohol fiber, the cement type is PII42.5R, the maximum particle size of the sand is 0.2mm, the fly ash is Class I fly ash, and the water reducer is polycarboxylate water reducer.

[0051] see figure 1 , image 3 , The concrete structure adopts two separated prisms, and there is a precast concrete crack between the two concrete, and the crack length is 100mm. Remove floating dust on the concrete surface, clean the surface, and after the surface is slightly dry, paste waterproof...

Embodiment 3

[0062] Embodiment 3, using multi-cracked cement-based composite materials, adopting the method of grinding and smoothing around the cracks, and repairing the concrete cracks on the surface of the dam body of hydraulic structures.

[0063] The weight ratio of the components of the multi-cracked cement-based composite material is cement: water: sand: fly ash: granulated blast furnace slag: metakaolin: water reducer: defoamer: thickener = 1:2.2:1.4:6.9: 0.55: 0.12: 0.008: 0.01: 0.005, also contains mixed fibers of aramid fiber and carbon fiber with a volume of 1.0% of the total volume of the composite material (the weight ratio of the two is 2: 1), the cement type is PII32.5R, sand The maximum particle size is 0.45mm, the fly ash is Class II fly ash, and the water reducer is polycarboxylate water reducer.

[0064] The construction steps are as follows:

[0065] 1) Polish and smooth the area extending about 35 mm from the cracks on the outer surface of the concrete in all directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com