Thick-specification pipeline steel cooling method

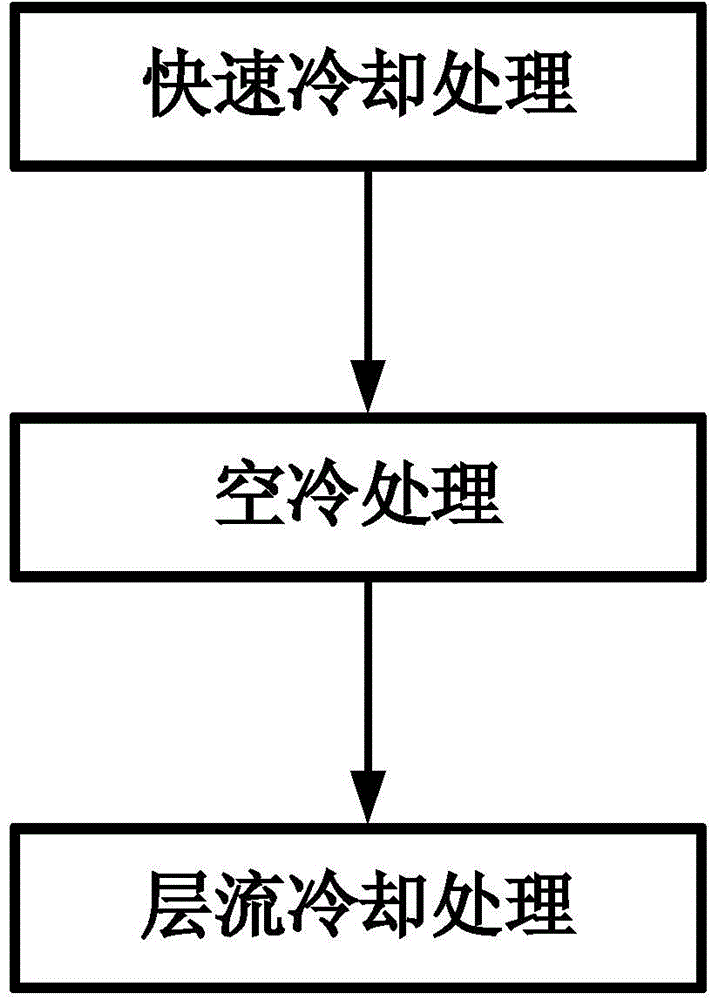

A cooling method and thick-gauge technology, which is applied in the field of heat treatment, can solve the problems of no obvious requirements for cooling speed and the reduction of toughness of thick-gauge pipeline steel, so as to avoid abnormal structures such as bainite/martensite and reduce the temperature gradient Affects, effects that improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

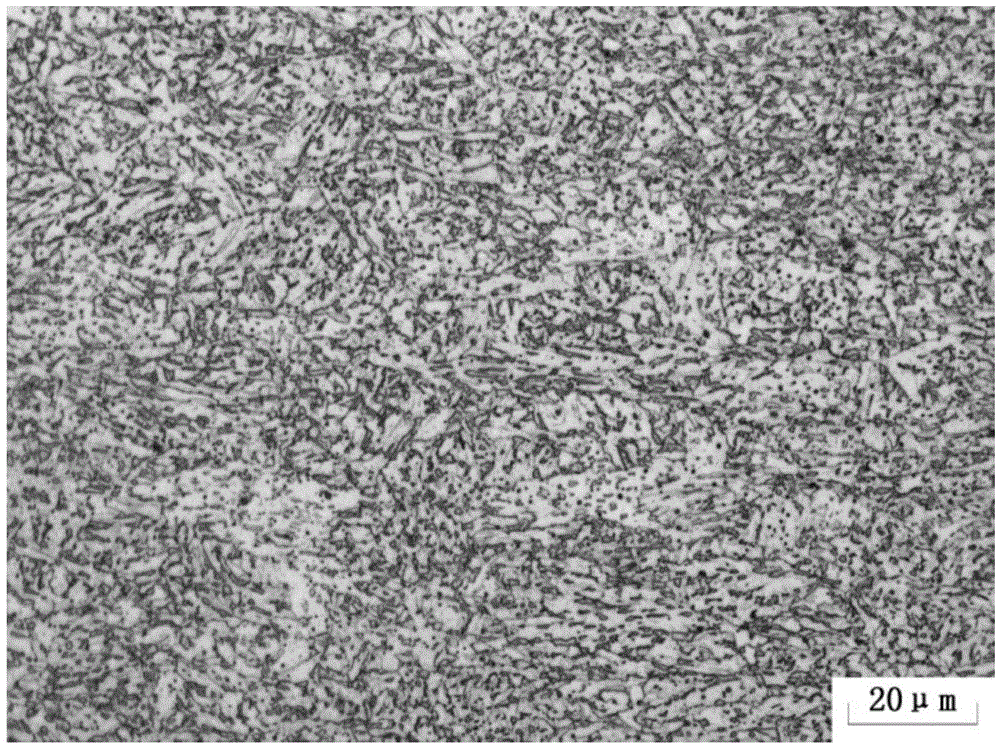

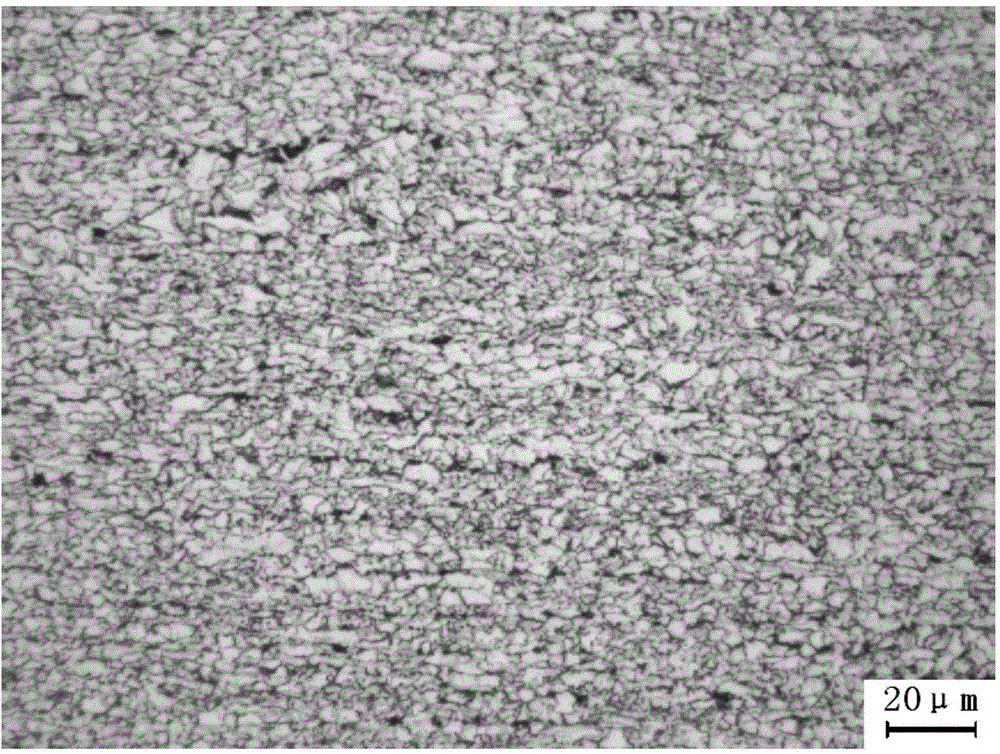

[0041] X80 grade thick specification pipeline steel, the specification is 18.4×1500mm (thickness×width), after finish rolling, it is rapidly cooled to 450℃ at a cooling rate of 10℃ / s, then air-cooled for 8s, and then laminar flow cooled to 400 ℃ coiled, its mechanical property is Rt 0.5 :572,R m : 636,A 50 : 44.0, -20°C Akv: 323, -15°C DWTT shear area SA%: 92.7.

Embodiment 2

[0047] X80 grade thick specification pipeline steel, the specification is 18.4×1500mm (thickness×width), after finish rolling, it is rapidly cooled to 620℃ at a cooling rate of 29℃ / s, then air-cooled for 17s, and then laminar flow cooled to 560 ℃ coiled, its mechanical property is Rt 0.5 :561,R m : 644,A 50 : 42.5, -20°C Akv: 362, -15°C DWTT shear area SA%: 91.3.

Embodiment 3

[0053] X80 grade thick specification pipeline steel, the specification is 18.4×1500mm (thickness×width), after finish rolling, it is rapidly cooled to 520℃ at a cooling rate of 21℃ / s, then air-cooled for 13s, and then laminar flow cooled to 460℃ ℃ coiled, its mechanical property is Rt 0.5 : 553MPa, R m : 682MPa, A 50 : 43.5%, -20°C Akv: 332J, -15°C DWTT shear area SA%: 98.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com