High-strength thick steel plate having excellent arrestability

A thick steel plate, high-strength technology, applied in the field of high-strength thick steel plate, to achieve the effect of excellent crack arrest and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

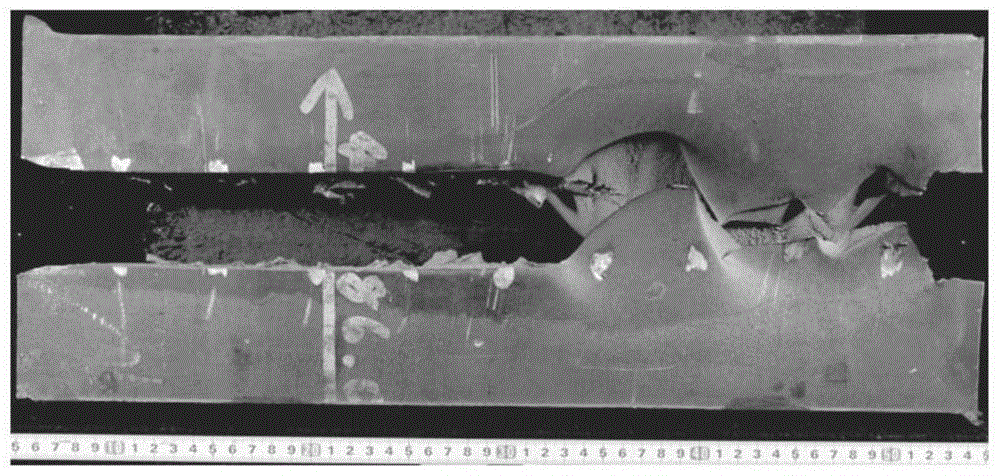

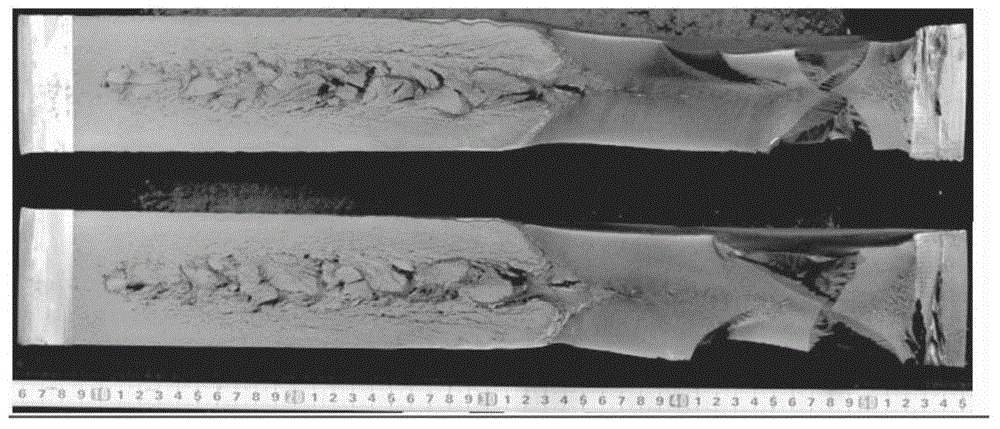

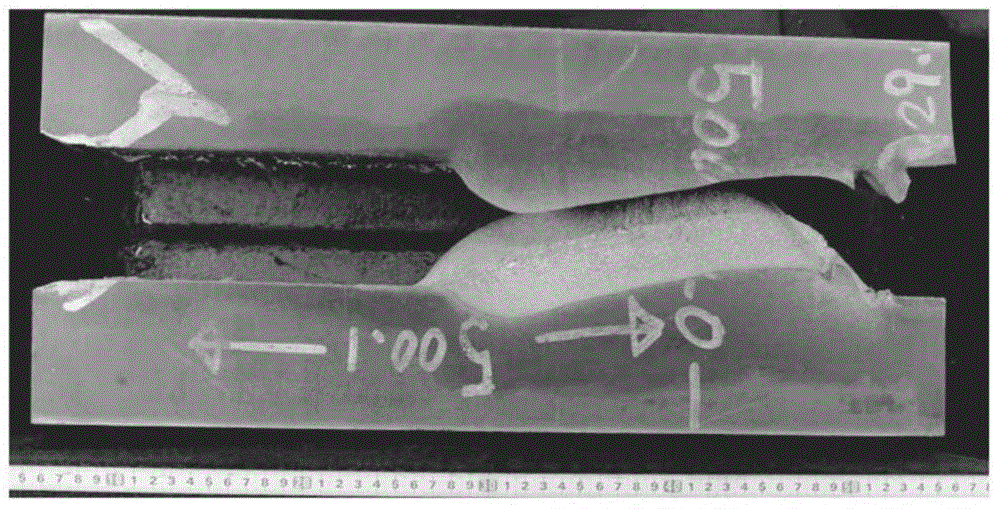

Image

Examples

Embodiment

[0192] The effects of the present invention will be described below based on examples.

[0193] In the steelmaking process, the component composition of molten steel was adjusted, and thereafter, steel sheets A to Z were produced by continuous casting. Steel sheets A to O are invention steels, and steel sheets P to Z are comparative steels.

[0194] In Examples 1 to 20 and Comparative Examples 21 to 55, the steel sheets A to Z were reheated and then plate rolled to form thick steel plates with a thickness of 60 to 95 mm, and then the steel plates were water cooled. However, in Comparative Example 53, air cooling was performed instead of water cooling. Thereafter, heat treatment is performed as necessary.

[0195] Table 1 and Table 2 show the component compositions of the steel sheets A to Z. Underlines in Table 1 and Table 2 indicate that the values are outside the scope of the present invention, and italics indicate the analysis values of the amounts contained as unavo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com