Two-dimensional area array ultrasonic transducer and manufacturing method thereof

An ultrasonic transducer and array technology, used in ultrasonic therapy, ultrasonic/sonic/infrasonic diagnosis, sonic diagnosis, etc., can solve the problem of difficulty in cutting through, the impact of ultrasonic transducer performance and life, the difficulty of lead welding process, etc. problems, to achieve the effect of simplifying complexity, good heat dissipation, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

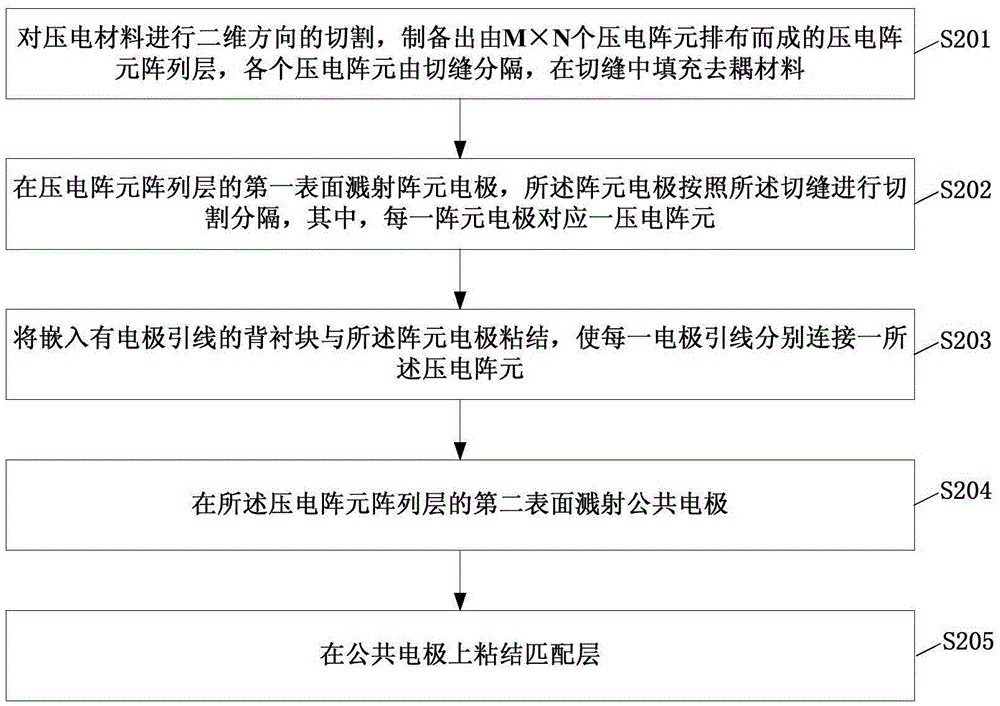

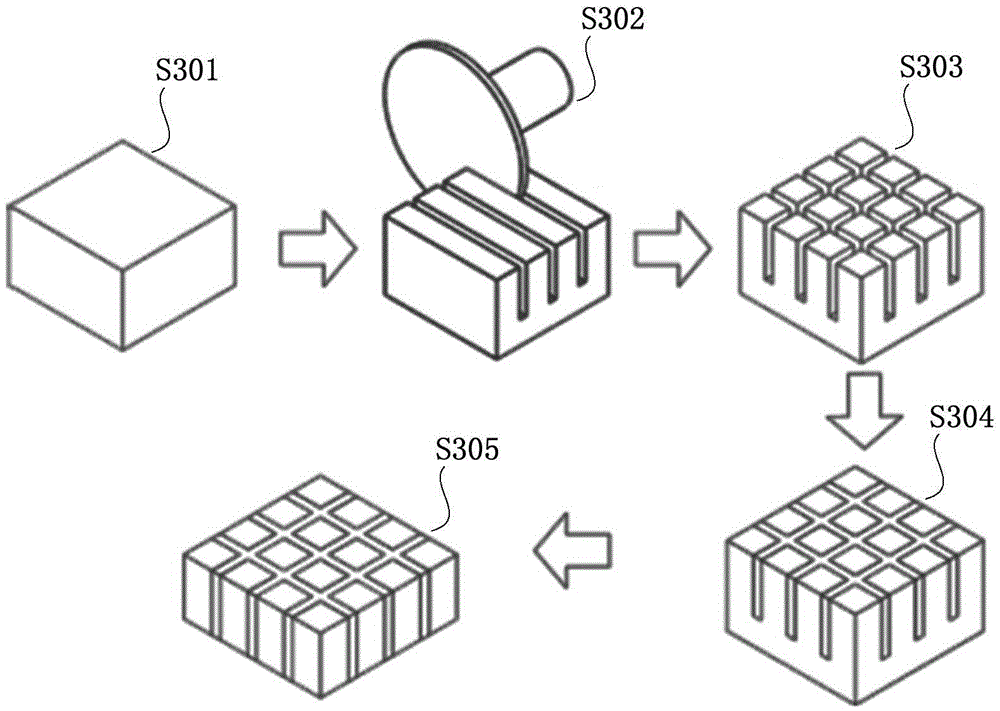

[0029] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

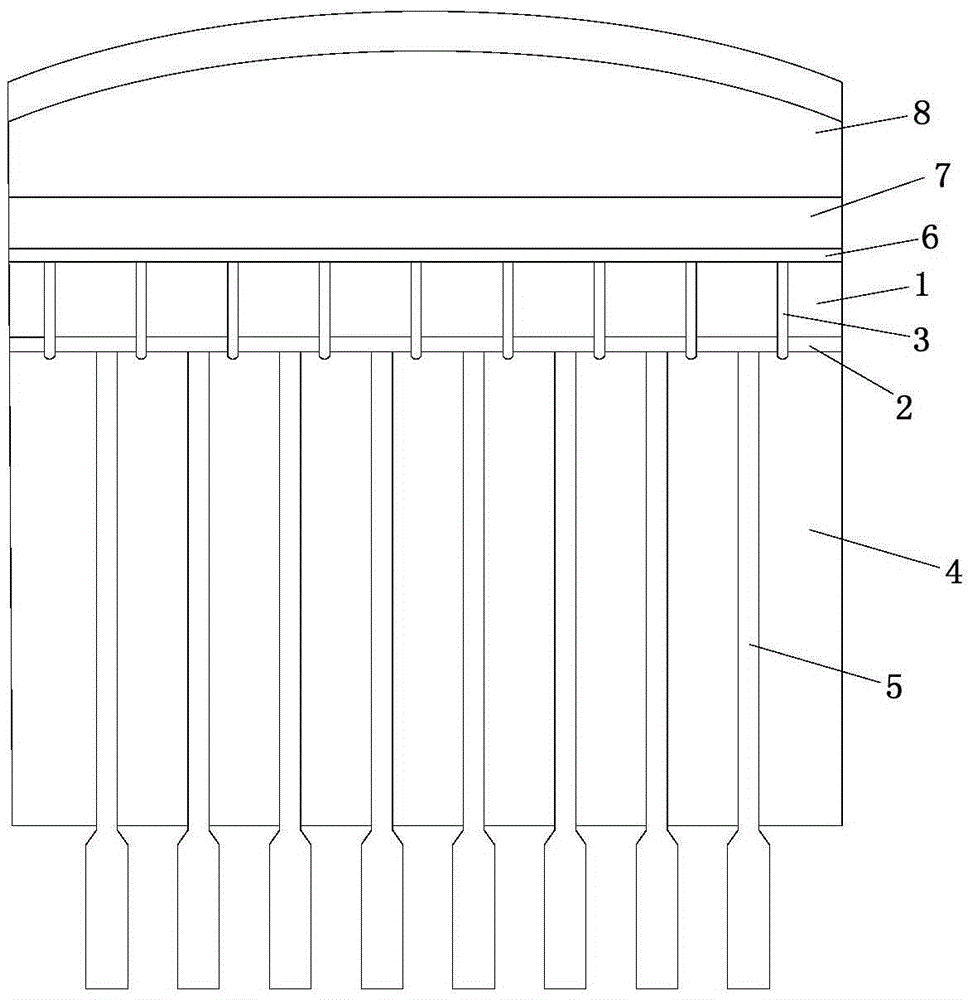

[0030] figure 1 It is a schematic structural diagram of a two-dimensional surface array ultrasonic transducer according to an embodiment of the present invention. Such as figure 1 As shown, the two-dimensional area array ultrasonic transducer includes:

[0031]The piezoelectric array element array layer 1 is formed by M×N piezoelectric array elements, and each piezoelectric array element is separated by a slit for receiving or transmitting ultrasonic signals. Wherein, the piezoelectric array element array layer 1 is a piezoelectric monomer or a piezoelectric composite material; the piezoelectric composite material can be a 1-3 type piezoelectric composite material or a 2-2 type piezoelectric composite material, such as a PZT piezoelectric ceramics.

[0032] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com