Method of improving quality of settled water from sludge return process by ultrasonic wave

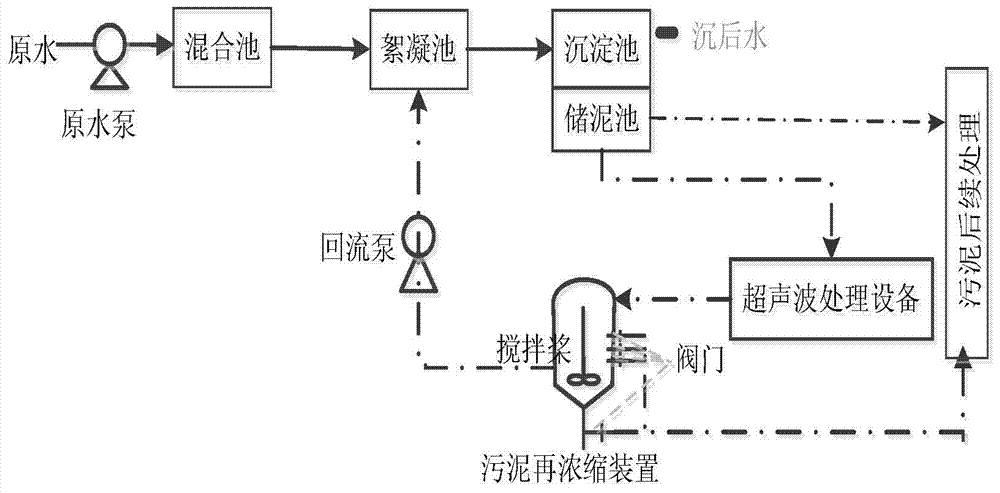

A sludge return and ultrasonic technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problem of increased sedimentation tank load, accumulation of pathogenic microorganisms, and reflocculation floc settlement performance To reduce the treatment load, improve water quality, and improve water supply safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The total solid mass concentration of the sludge entering the ultrasonic treatment equipment is 1300mg / L, and the COD in the supernatant Cr The concentration of E. coli and fecal E. coli in the initial sludge were 1.25×10 4 ,407CFU / mL, the particle size of sludge floc is 25.66μm. After the ultrasonic frequency is 25KHz, the sound energy density is 23.3W / L (power is 350W, sludge volume is 15L), after 30 minutes of action, the COD in the supernatant Cr Increased to 67.45mg / L, the dissolution rate reached 539%, which was 6.4 times the initial concentration; the inactivation rates of Escherichia coli and fecal Escherichia coli were 23.5% and 30.2% respectively; up to 20.4%. The sludge after ultrasonic treatment is re-concentrated through the sludge re-concentration device, the re-concentration coefficient is 0.6, the solid content rate is 0.095w / w%, and then the stirring blade is started at a speed of 50rpm, and the volume reflux ratio is 8%. Raw water with an initial tu...

Embodiment 2

[0027] The total solid mass concentration of the sludge entering the ultrasonic treatment equipment is 1300mg / L, and the COD in the supernatant Cr The concentration of E. coli and fecal E. coli in the initial sludge were 1.25×10 4 ,407CFU / mL, the particle size of sludge floc is 25.66μm. After the ultrasonic frequency is 40KHz, the sound energy density is 30W / L (the power is 450W, and the sludge volume is 15L), after 15 minutes of action, the COD in the supernatantCr Increased to 77.45mg / L, the dissolution rate reached 634%, which was 7.3 times the initial concentration; the inactivation rates of Escherichia coli and fecal Escherichia coli were 20.5% and 35.2% respectively; up to 22.7%. The sludge after ultrasonic treatment is re-concentrated through the sludge re-concentration device, the re-concentration coefficient is 0.6, and the solid content rate is 0.12w / w%. For the raw water with an initial turbidity of 3.50NTU, the turbidity of the sinking water increased from 69.69%...

Embodiment 3

[0029] The total solid mass concentration of the sludge entering the ultrasonic treatment equipment is 4500mg / L, and the COD in the supernatant Cr was 27.59mg / L, and the concentrations of E. coli and fecal E. coli in the initial sludge were 2.31×10 4 ,609CFU / mL, the particle size of sludge floc is 22.66μm. After the ultrasonic frequency is 125KHz, the sound energy density is 30W / L (the power is 450W, and the sludge volume is 15L), after 20 minutes of action, the COD in the supernatant Cr Increased to 167.45mg / L, the dissolution rate reached 507%, which was 6.1 times the initial concentration; the inactivation rates of Escherichia coli and fecal Escherichia coli were 24.5% and 39.2% respectively; up to 24.9%. The sludge after ultrasonic treatment is re-concentrated through the sludge re-concentration device, the re-concentration coefficient is 0.75, and the solid content rate is 0.18w / w%. For raw water with an initial turbidity of 20.0NTU, the turbidity of the sinking water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com