Ultrasonic ozone treating technique of chlorophenol-containing wastewater

A technology of ozone treatment and chlorophenol, which is applied in the direction of oxidized water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high energy consumption, difficulty in adapting to multi-component wastewater, and economical process conditions Poor performance and other problems, to achieve the effect of low energy consumption, great market development prospects, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

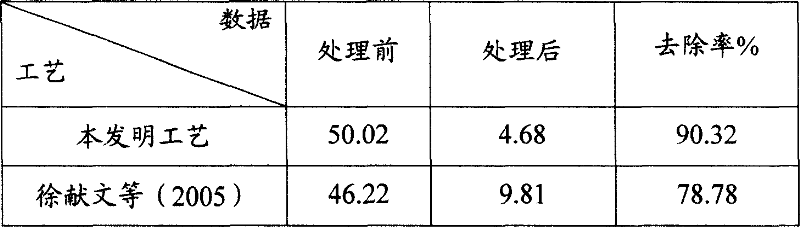

[0032] Implementation plan: Ultrasonic ozone oxidation treatment process for waste water containing 50.02 mg / L of p-chlorophenol, using a stainless steel reaction tank, and the ozone input is in contact with the waste water through a microporous diffuser fixed on the bottom of the reaction tank. O 3 and water vapor pyrolyze in the cavitation bubble to produce OH, and realize the deep oxidation and decomposition of p-2-chlorophenol pollutants, so as to achieve the purpose of ultrasonic ozonation treatment of p-chlorophenol-containing wastewater. The wastewater treatment results are shown in Table 1, and Xu Xianwen et al. (2005, J.Zhejiang SCI 6B (6)) reported the results for comparison.

[0033] Table 1: Wastewater Treatment Results

[0034]

[0035] Monitoring method: Chlorophenol adopts the liquid chromatography analysis and detection method stipulated in "Water and Wastewater Monitoring and Analysis Methods" compiled by the State Environmental Prot...

Embodiment 2

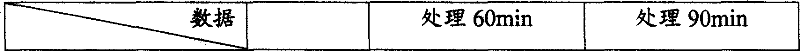

[0038] Other conditions are with embodiment 1, waste water contains chlorophenol (the mixture of ortho-chlorophenol, p-chlorophenol, m-chlorophenol) 200mg / L, at sound wave frequency 40kHz, ozone level 10mg / L h, hydraulic retention time 60min and Under the process conditions of 90min, the removal effect of o-chlorophenol by the sonic energy density (50, 100, 150W / L) was compared, and the treatment results are shown in Table 2.

[0039] Table 2: Wastewater treatment results under different acoustic energy densities

[0040]

[0041]

[0042] The results in Table 2 show that the increase of ultrasonic sound energy density is helpful for the removal of p-chlorophenol. After 90 minutes, the removal of chlorophenol increased from 77.9% to 80.4%. However, the increase rate of chlorophenol removal rate decreased. When 50W / L increased to 100W / L, the removal rate of chlorophenol increased by 5.2 percentage points. When 100W / L increased to 150W / L, the removal rate of ...

Embodiment 3

[0044] Other conditions are with embodiment 2, and sound energy density is 100W / L, and hydraulic retention time 90min in the tank compares ozone amount (10mg / L h, 20mg / L h, 30mg / L h) p-chlorophenol removal effect, See Table 3 for the processing results.

[0045] Table 3: Wastewater treatment results under different ozone levels

[0046]

[0047] The results in Table 3 show that the increase in the amount of ozone contributes to the removal of chlorophenol, and the removal of chlorophenol increases from 90.7% to 94.4%. However, the increase rate of chlorophenol removal rate decreased. When the amount of ozone increased from 10mg / L·h to 20mg / L·h, the removal of chlorophenol increased by 12.8 percentage points, and when 20mg / L·h increased to 30mg / L·h , chlorophenol removal increased by 3.7 percentage points. For higher concentrations of chlorophenol wastewater, it is necessary to increase the amount of ozone appropriately.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com