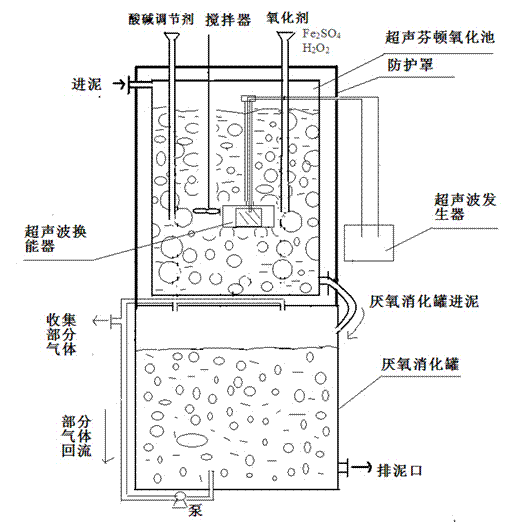

Method and equipment for processing industrial sludge through ultrasonic wave in combination with Fenton reaction and anaerobic digestion

A technology of Fenton reaction and industrial sludge, applied in the oxidation treatment of sludge, sludge treatment, biological sludge treatment, etc., can solve the problems of high cost, increase the degree of inorganicization of sludge, etc. The effect of reducing equipment maintenance risks and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Pass the beer sludge sewage mixture into the ultrasonic Fenton reaction tank, H 2 O 2 The dosage of 11 g / L, Fe 2+ The dosage is 0.5 g / L, and sulfuric acid is added to adjust the pH to 1.5-2.0, the reaction time is 0.5 h, the reaction temperature is 50 °C, and the acoustic energy density of ultrasonication is set to 0.1 w / m 3 , ultrasonic time = 10 min; the anaerobic digestion tank is connected to the bottom of the ultrasonic Fenton reaction tank. The anaerobic digestion tank is equipped with a biogas outlet pipe, a sludge outlet pipe and a sewage outlet pipe. The sewage outlet pipe is connected to the sewage sedimentation tank and then to the recovery water tank. , the treated sludge can be directly used as the raw material of organic fertilizer, and a small amount of sewage at the outlet of the anaerobic digestion tank can be discharged after precipitation.

Embodiment 2

[0028] Pass the municipal sludge sewage mixture into the ultrasonic Fenton reaction tank, H 2 O 2 The dosage of 11 g / L, Fe 2+ The dosage is 0.8 g / L, and sulfuric acid is added to adjust the pH to 2.0-3.0, the reaction time is 1.5 h, the reaction temperature is 60 °C, and the acoustic energy density of ultrasonication is set to 0.2 w / m 3, the ultrasonic time is 30 min; the anaerobic digestion tank is connected to the bottom of the ultrasonic Fenton reaction tank. The anaerobic digestion tank is equipped with a biogas outlet pipe, a sludge outlet pipe and a sewage outlet pipe. The sewage outlet pipe is connected to the sewage sedimentation tank and then to the recovery water tank. The treated sludge can be directly used as the raw material of organic fertilizer, and a small amount of sewage at the outlet of the anaerobic digestion tank can be discharged after sedimentation.

Embodiment 3

[0030] Pass the starch plant sludge sewage mixture into the ultrasonic Fenton reaction tank, H 2 O 2 The dosage of 15 g / L, Fe 2+ The dosage is 1 g / L, and sulfuric acid is added to adjust the pH to 2.0-3.0, the reaction time is 1.5 h, the reaction temperature is 60 °C, and the acoustic energy density of ultrasonication is set to 0.3 w / m 3 , the ultrasonic time is 50 min; the anaerobic digestion tank is connected to the bottom of the ultrasonic Fenton reaction tank. The anaerobic digestion tank is equipped with a biogas outlet pipe, a sludge outlet pipe and a sewage outlet pipe. The sewage outlet pipe is connected to the sewage sedimentation tank and then to the recovery water tank. The treated sludge can be directly used as the raw material of organic fertilizer, and a small amount of sewage at the outlet of the anaerobic digestion tank can be discharged after sedimentation.

[0031] Example 3

[0032] Passing the colored sludge sewage mixture from the textile factory int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com