High-sound-energy-density single-slot vacuum frequency-mixing immersion type ultrasonic surface treatment device

An ultrasonic and immersion technology, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of complex curved surfaces and inner surface processing of workpieces, and high requirements for size and shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

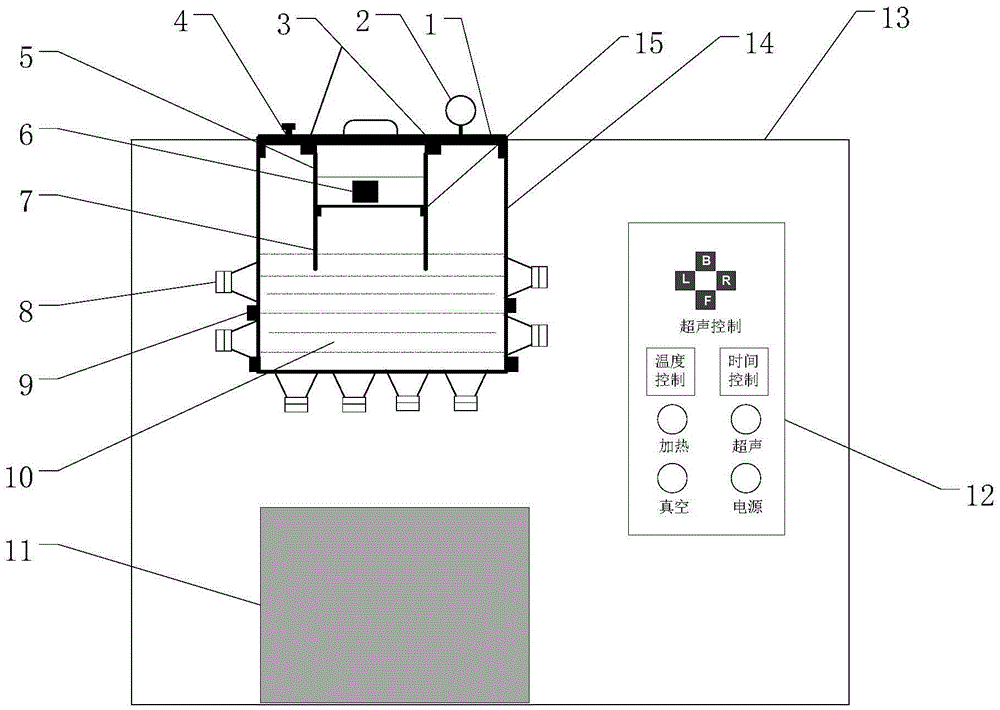

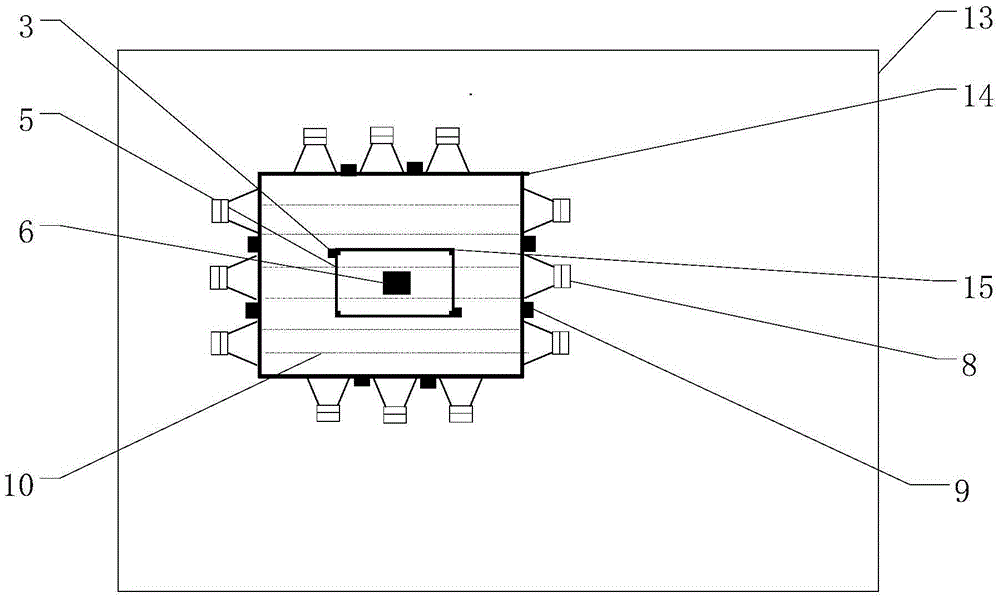

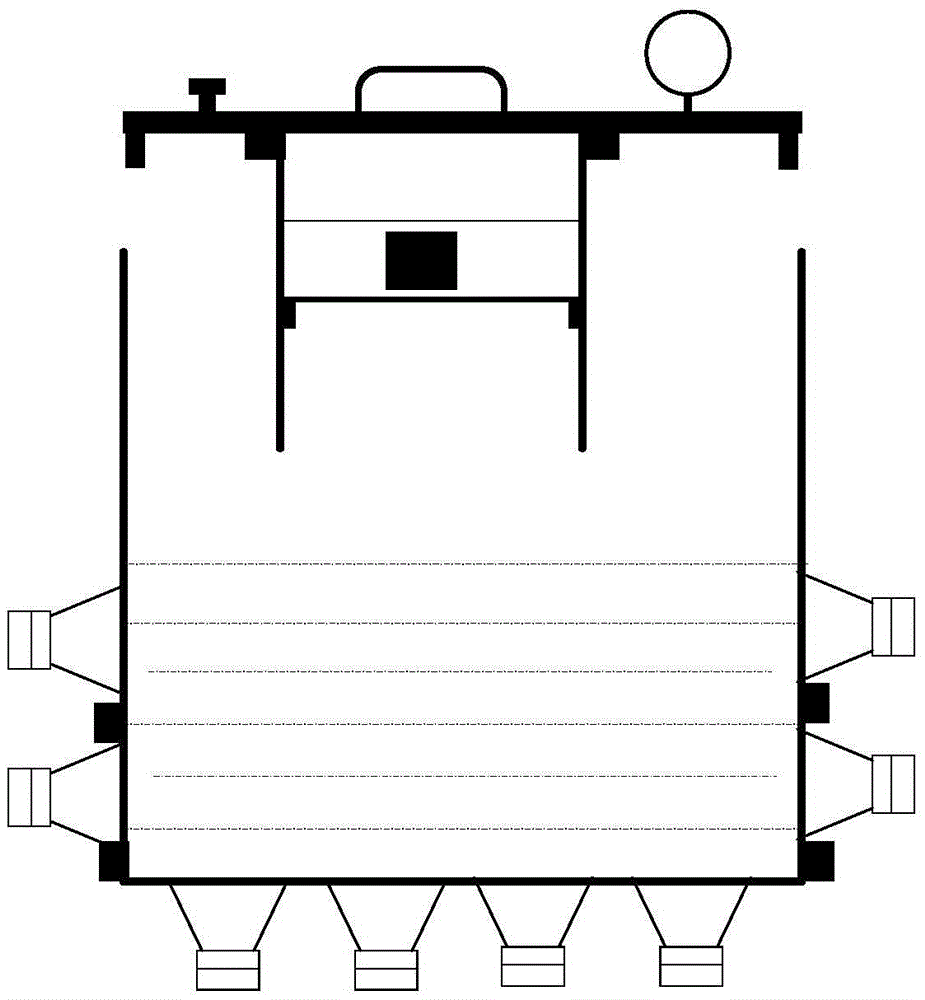

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0017] Step 1: configuring a processing fluid (10) according to the base material of the product to be processed (6) and the roughness of the surface, and adding the prepared processing fluid into the processing pool (14) in the ultrasonic processing equipment;

[0018] Step 2: Put the product to be processed (6) in the processing basket (5), and fix the position to prevent the product to be processed from floating and shifting during ultrasonic processing, and adjust the position of the supporting leg (15) of the processing basket in advance according to the requirements. Height, the bottom of the supporting foot is equipped with a buffer pad, the switch of the electromagnet (3) is turned on, and the processing basket is adsorbed on the processing cover (1);

[0019] Step 3: Start the temperature control module (9) and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com