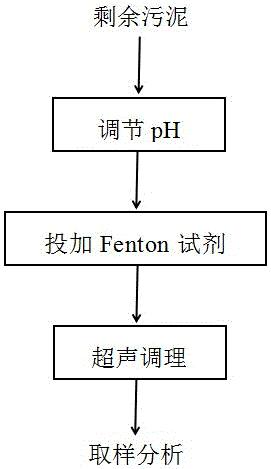

Method for conditioning urban sewage plant excess sludge through ultrasound and Fenton cooperation

A technology for excess sludge and urban sewage, applied in dehydration/drying/concentration sludge treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of weak hydrolysis of solid debris, low efficiency, high operating costs, etc. Achieve the effects of facilitating subsequent sludge treatment, broad application prospects, and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Treatment of excess sludge in the thickening tank of the urban sewage treatment plant operated by the circulating activated sludge method (CASS) as the biochemical treatment process.

[0036] The sludge specific resistance (SRF) of the sewage plant is greater than 1×10 12m / kg, it is not suitable for direct mechanical dehydration and needs to be pretreated. The moisture content of the raw sludge is high, and it is still about 72% after dehydration, which does not meet the requirements for the moisture content of the landfill sludge in the "Sludge Disposal of Municipal Sewage Treatment Plant Mixed Landfill Mud" (GB / T 23485-2009) . The ratio of MLVSS to MLSS in the thickened sludge mixture is about 0.45, indicating that the organic matter content in the sludge of this plant is relatively low. At the same time, the SCOD in the sludge is only 55-70 mg / L, indicating that the dissolved organic matter in the sludge itself is less. It has a low binding force wit...

Embodiment 2

[0038] Embodiment 2: Treating the excess sludge in the thickening tank of the urban sewage treatment plant operated with the A / O process as the biochemical treatment process.

[0039] Analysis of the characteristics of the sludge in this plant shows that its SRF is greater than 1×10 13 m / kg, which belongs to the difficult-to-dewater sludge, and the moisture content is still greater than 75% after direct dehydration without conditioning, which does not meet the requirements specified in the "Mud Quality for Mixed Landfill Sludge Disposal in Urban Sewage Treatment Plants" (GB / T23485-2009). Requirements for moisture content of buried sludge. The sludge MLVSS / MLSS is about 0.68, indicating that the organic matter content in the sludge is relatively high, but at the same time, the SCOD is 195.65 mg / L, and the organic matter dissolved in the sludge itself is less, and a large amount of organic matter is in the form of cell inclusions or floc structures. , The form of cell structur...

Embodiment 3

[0041] Example 3: Treatment of excess sludge in a concentration tank of an urban sewage treatment plant operated with a Carrousel oxidation ditch delayed aeration activated sludge treatment process as a biochemical treatment process.

[0042] The SRF of the sludge from the sewage plant is greater than 1×10 13 m / kg, which is also difficult to dewater sludge, and the water content after dehydration exceeds 80%, which does not meet the requirements for landfill sludge in the "Sludge Disposal of Municipal Sewage Treatment Plants for Mixed Landfill" (GB / T 23485-2009). Requirements for water content The sludge MLVSS / MLSS is about 0.61. The organic matter content in the sludge is relatively high. At the same time, the SCOD is about 400 mg / L. The sludge itself can dissolve more organic matter, and the other part of the organic matter is the cell content Or the form of floc structure and cell structure exists in the sludge, and the water is bound between the structures and it is diffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com