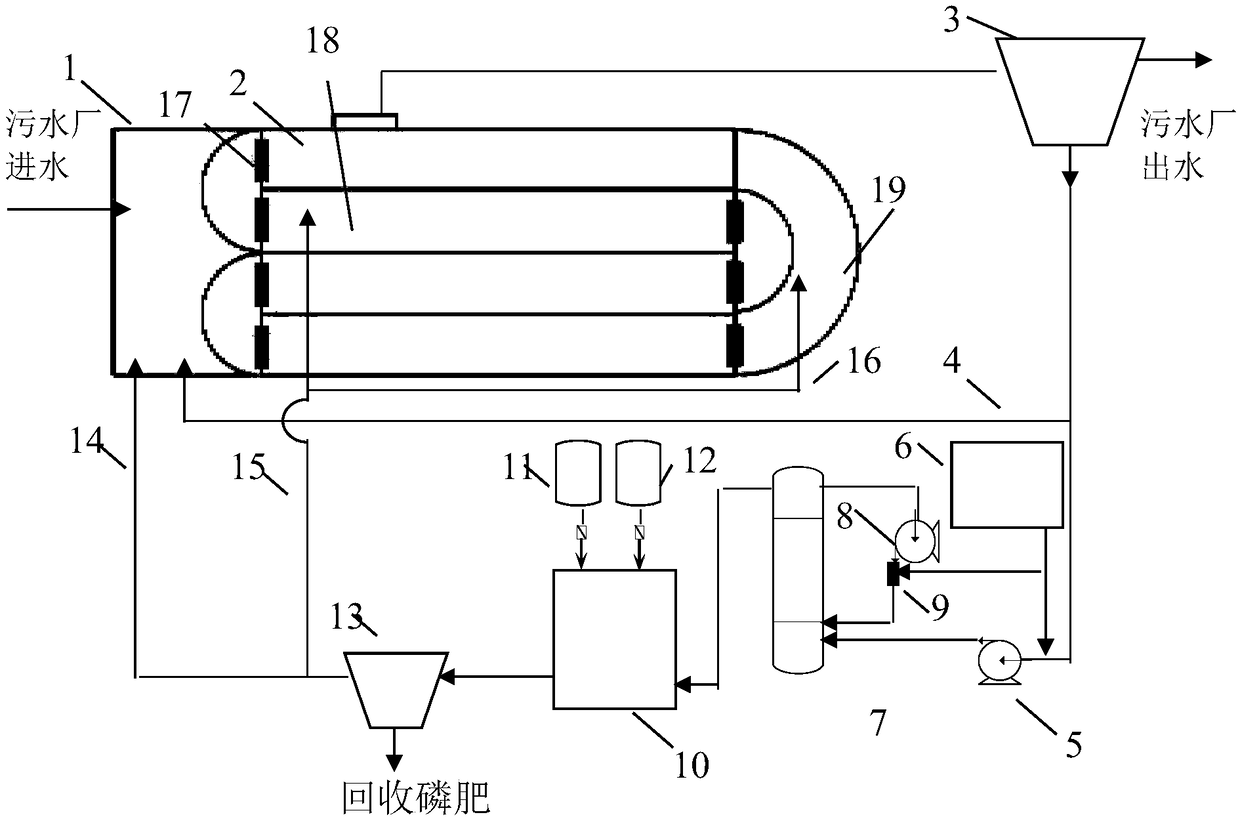

Ultrasonic ozone compound sludge reducing method coupled with Carrousel oxidation ditch and equipment thereof

A technology of sludge reduction and carrousel, which is applied in the direction of oxidation treatment of sludge, chemical instruments and methods, sludge treatment, etc., can solve the problems of difficult stable operation, complex process, and poor stability of methane recovery process, etc. , to achieve the effects of improving economic applicability, simple process control, and strengthening lysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] For the excess sludge reduction process of a small sewage treatment plant, the excess sludge discharged from the secondary sedimentation tank first enters the ultrasonic composite ozone reactor, starts the ozone generator, and performs ultrasonic composite ozone lysis reduction treatment, the ozone concentration It is 20mg / L, the dosage of ozone is 0.01gO3 / g TSS, and the ozone pressure is 0.05Mpa. The feed dosing point of the sludge mixture adopts the method of dosing in front of the pump to do the ozone dosing. The vacuum degree in front of the pump is controlled to be 0.1Mpa. The mixed liquid flow ratio in the mixture is 1:1.

[0044]The ozonated sludge reduction reactor adopts a closed cylindrical reactor, and a stainless steel screen loaded with MnO is installed. The aperture of the screen is 100 mesh, and the distance between the screens in the reactor is 200mm. The air pressure in the reaction tank is 0.05Mpa, the appropriate pH value is 6, the residence time of ...

Embodiment 2

[0048] For the excess sludge reduction process of a sewage treatment plant with a treatment scale of 50,000 tons per day, the excess sludge discharged from the secondary sedimentation tank first enters the ultrasonic composite ozone reactor, starts the ozone generator, and performs ultrasonic composite ozone lysis and reduction deal with.

[0049] The feed dosing point of the sludge mixture adopts the method of dosing in front of the pump, and adopts the process of circulating in the reactor to ensure that the ozone dosing amount reaches 0.1gO3 / g TSS through the reflux process. The ozone concentration generated by the ozone generator is 50mg / L, the ozone pressure is 0.1Mpa, the vacuum degree before the pump is 0.1Mpa, and the flow ratio of the ozone gas to the mixed liquid in the pipeline is 1:1.

[0050] The ozonated sludge reduction reactor adopts a closed cylindrical reactor, and a stainless steel screen loaded with MnO is installed. The aperture of the screen is 120 mesh, ...

Embodiment 3

[0055] For the excess sludge reduction process of a sewage treatment plant with a treatment scale of 80,000 tons per day, the excess sludge discharged from the secondary sedimentation tank first enters the ultrasonic composite ozone reactor, starts the ozone generator, and performs ultrasonic composite ozone lysis and reduction deal with.

[0056] The feed dosing point of the sludge mixture adopts the method of dosing in front of the pump, and adopts the process of circulating in the reactor to ensure that the ozone dosing amount reaches 0.05gO3 / g TSS through the reflux process. The ozone concentration generated by the ozone generator is 30mg / L, the ozone pressure is 0.05Mpa, the vacuum degree before the pump is 0.2Mpa, and the flow ratio of the ozone gas to the mixed liquid in the pipeline is 1.5:1.

[0057] The ozonated sludge reduction reactor adopts a closed cylindrical reactor, and a stainless steel screen loaded with MnO is installed. The aperture of the screen is 110 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com