Production method of super-toughness engineering plastic of nylon 6/ polycarbonate/ elastomer/ HDI

A polycarbonate, engineering plastics technology, applied in the field of super tough engineering plastics manufacturing, can solve problems to be expanded and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

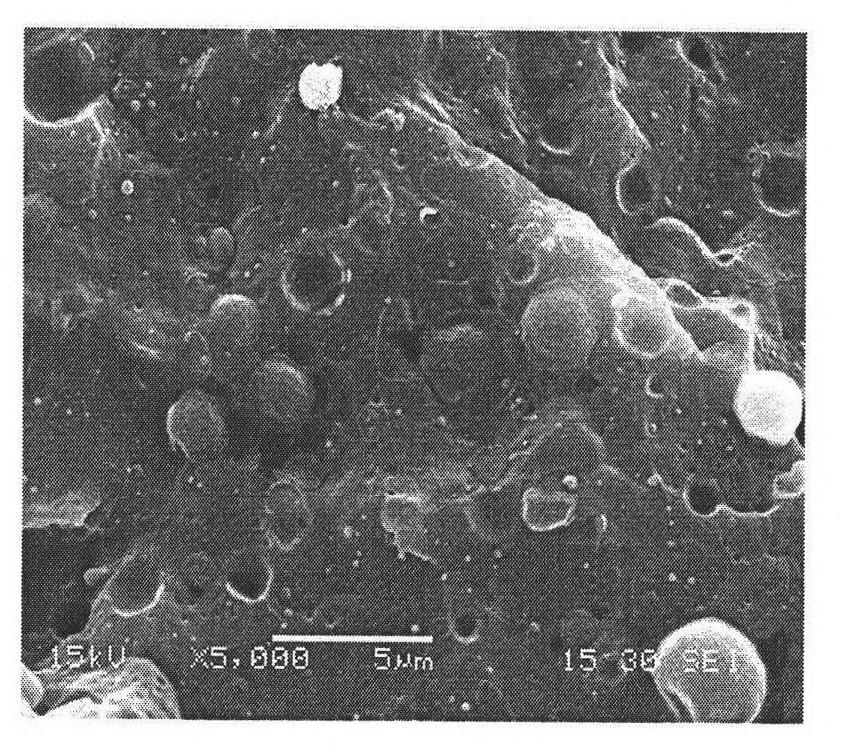

Image

Examples

Embodiment 4-9

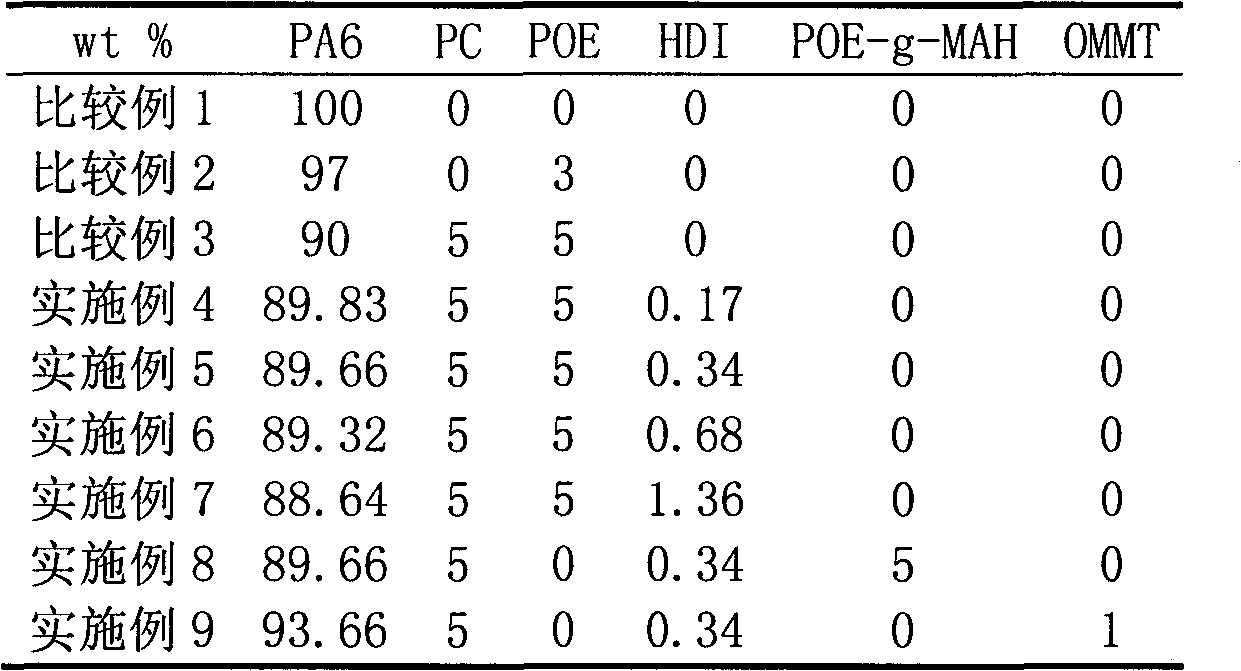

[0045] Nylon 6 and polycarbonate were dried in a high-performance vacuum dehumidification dryer at 90°C for 12 hours, and PA6, PC, POE, HDI, POE-g-MAH, and OMMT were mixed uniformly in the proportions described in Table 1. The rest are the same as Comparative Examples 1-3, and relevant data are listed in Tables 1 and 2.

[0046] Table 1.

[0047]

[0048] Table 2.

[0049]

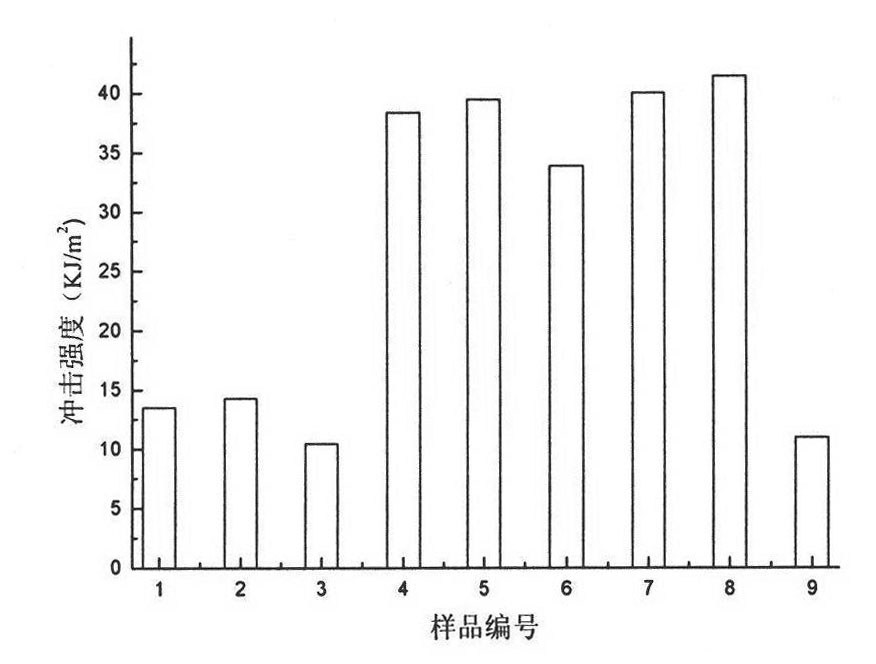

[0050] Such as figure 2 As shown, the notched impact strength of the sample after adding HDI is 3-4 times higher than that of the sample without HDI, reaching 40.03kJ / m 2 , become a "super tough" material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com