Graphene preparation method and graphene prepared through graphene preparation method

A technology of graphene and graphene suspension, which is applied in the field of graphene and can solve the problems of low yield of single-layer graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

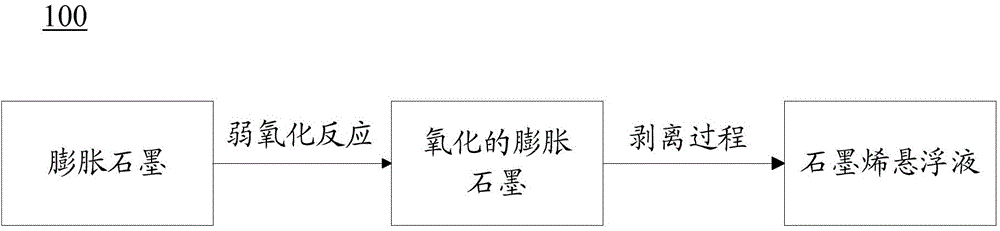

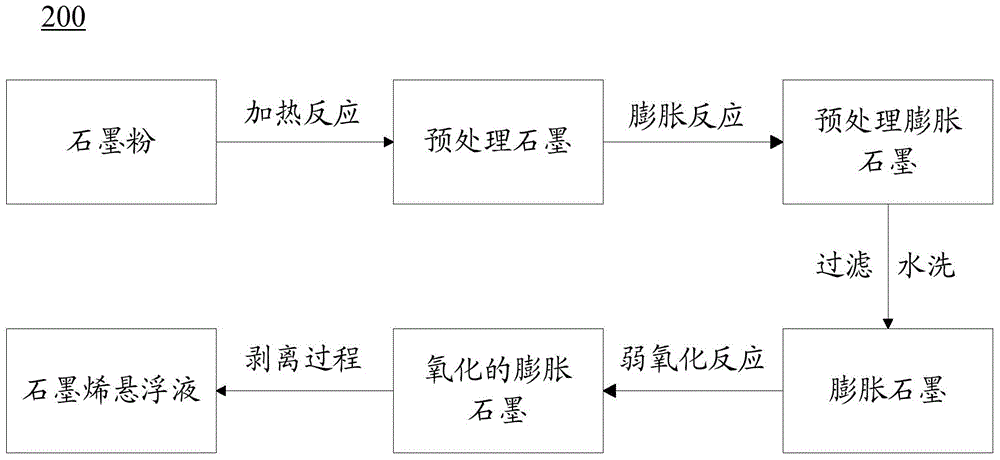

Method used

Image

Examples

Embodiment 1

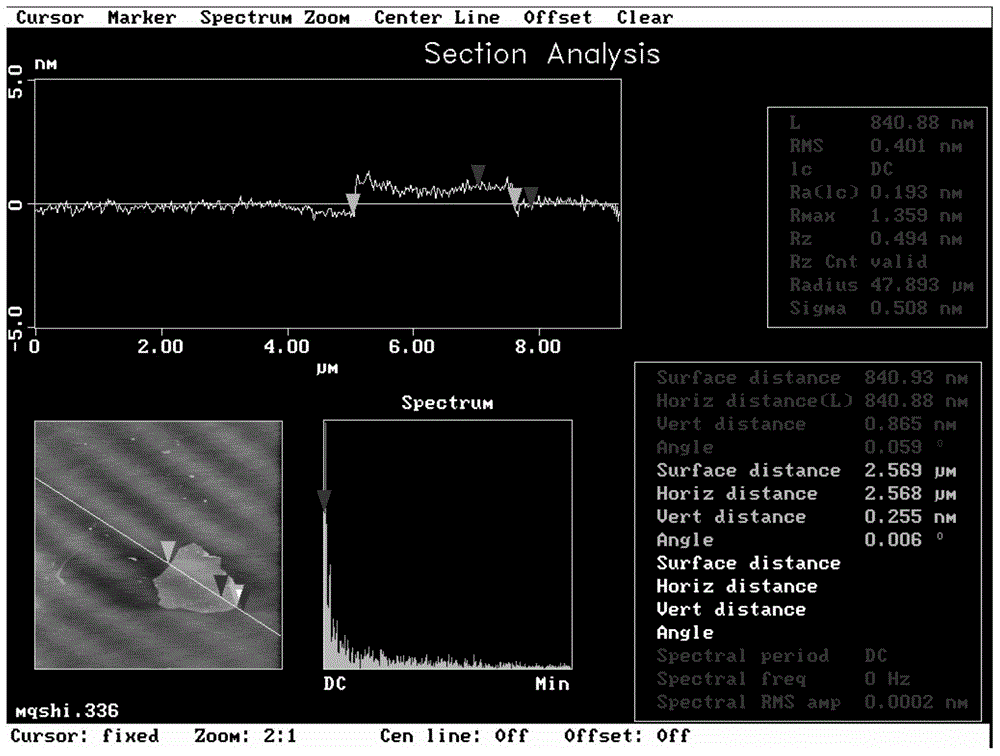

[0078] Weigh 0.2 g of 200-mesh graphite powder and place it in a 50 ml reactor, add 3 ml of chlorosulfonic acid to mix, put the mixture in a polytetrafluoroethylene reactor at 120° C. and heat for 5 hours to obtain pretreated graphite. Subsequently, the pretreated graphite is taken out and 15ml of concentrated sulfuric acid is added, and 6ml of hydrogen peroxide solution is added dropwise under stirring conditions to make the pretreated graphite gradually expand, and the pretreated expanded graphite is obtained after 1 hour of reaction, which is added to the pretreated expanded graphite. Water is added to separate the pretreated expanded graphite from the solution, and the obtained expanded graphite product is filtered, washed with water, and dried to obtain the expanded graphite. Take 50 mg of the expanded graphite, mix it with potassium chlorate in a ratio of 1:3, and add 12 ml of a mixed solution of concentrated sulfuric acid and nitric acid (the ratio of concentrated sulfur...

Embodiment 2

[0080] Weigh 0.2 g of 325-mesh graphite powder and place it in a 50 ml reactor, add 3 ml of chlorosulfonic acid for mixing, put the mixture in a polytetrafluoroethylene reactor at 120° C. and heat for 5 hours to obtain pretreated graphite. Subsequently, the pretreated graphite was taken out and 15ml of concentrated sulfuric acid was added, and 6ml of hydrogen peroxide solution was added dropwise under agitation to gradually expand the pretreated graphite, and the pretreated expanded graphite was obtained after 10 minutes of reaction. Water is added to separate the pretreated expanded graphite from the solution, and the obtained expanded graphite product is filtered, washed with water, and dried to obtain the expanded graphite. Take 50 mg of the expanded graphite, mix it with potassium chlorate in a ratio of 1:3, and add 12 ml of a mixture of concentrated sulfuric acid and nitric acid (the ratio of concentrated sulfuric acid and nitric acid in the mixture is 3:1), mix and place ...

Embodiment 3

[0082] Weigh 0.2 g of 325-mesh graphite powder and place it in a 50 ml reactor, add 6 ml of chlorosulfonic acid to mix, put the mixture in a polytetrafluoroethylene reactor at 120° C. and heat for 5 hours to obtain pretreated graphite. Subsequently, the pretreated graphite was taken out and 15ml of concentrated sulfuric acid was added, and 10ml of hydrogen peroxide solution was added dropwise under agitation to gradually expand the pretreated graphite, and the pretreated expanded graphite was obtained after 5 hours of reaction. Water is added to separate the pretreated expanded graphite from the solution, and the obtained expanded graphite product is filtered, washed with water, and dried to obtain the expanded graphite. Take 50 mg of the expanded graphite, mix it with potassium chlorate in a ratio of 1:2, and add 12 ml of a mixture of concentrated sulfuric acid and nitric acid (the ratio of concentrated sulfuric acid and nitric acid in the mixture is 3:1), mix and place to rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carbon to oxygen ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com