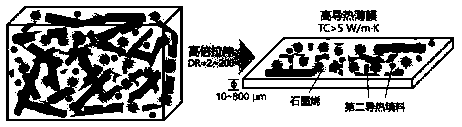

Polymer heat-conducting film containing uniformly-dispersed and highly-oriented graphene, and preparation method thereof

A heat-conducting film and graphene technology, applied in chemical instruments and methods, flat products, heat exchange materials, etc., can solve problems such as poor heat resistance, weak interface bonding, material fatigue, etc., and achieve improved thermal conductivity and gas barrier performance , improve the degree of orientation of fillers, and ensure the effect of performance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a polymer heat-conducting film containing homogeneously dispersed and highly oriented graphene, comprising the following steps:

[0044] The first step, graphene modified composite material: at 160 °C, 30 parts of PE, 40 parts of graphene (brand ENN-HTC-5L, ENN Graphene Technology Co., Ltd.), 30 parts of boron nitride, 20 parts Add EVA, 20 parts of paraffin, 4 parts of silane coupling agent KH560, 13 parts of white oil, 2 parts of ACR, 2 parts of MBS, 1.5 parts of zinc stearate, 0.5 parts of antioxidant 168 and 1 part of antioxidant 1010 "High-shear melt blending" is carried out in the internal mixer, and after the ratio of the output energy of mixing to the mass of all mixtures reaches 1 kWh / kg, the graphene-modified composite material is obtained by cooling and granulating;

[0045] The second step, graphene-modified heat-conducting film: the graphene-modified composite material obtained in S11 is subjected to the "high thermal stretching" proce...

Embodiment 2

[0047] A method for preparing a polymer heat-conducting film containing homogeneously dispersed and highly oriented graphene, comprising the following steps:

[0048] The first step, graphene modified composite material: at 120 ℃, 80 parts of PVC, 5 parts of graphene (brand ENN-HTC-5L, ENN Graphene Technology Co., Ltd.), 15 parts of carbon nanotubes (brand ENN -CMw11, Xinao Graphene Technology Co., Ltd.), 10 parts of paraffin, 0.015 parts of titanate and 5 parts of epoxidized soybean oil are added to a high-speed mixer for "high-shear melt blending", and the mixing output energy is consistent with all After the mass ratio of the mixture reaches 0.1 kWh / kg, a graphene-modified composite material is obtained;

[0049] The second step, graphene-modified heat-conducting film: the graphene-modified composite material obtained in S21 is subjected to a "high-power thermal stretching" process at 160 °C through a sheet extruder equipped with a conical twin-screw extruder, DR Set to 2,...

Embodiment 3

[0051] A method for preparing a polymer heat-conducting film containing homogeneously dispersed and highly oriented graphene, comprising the following steps:

[0052] The first step, graphene modified composite material: at 250 ℃, 60 parts of PC, 20 parts of graphene (brand ENN-HTC-5L, ENN Graphene Technology Co., Ltd.), 20 parts of magnesium oxide, 10 parts of SBS , 2 parts of aluminate, 0.4 part of antioxidant 168 and 0.8 part of antioxidant 1010 are added to the twin-screw extruder for "high-shear melt blending", and the ratio of mixing output energy to the mass of all mixtures reaches 2 After kWh / kg, the graphene modified composite material is obtained;

[0053] The second step, graphene-modified heat-conducting film: the graphene-modified composite material obtained in S31 is subjected to the "high thermal stretching" process through a cast film machine at 250 °C, and the DR is set to 20. When the film forming thickness reaches 100 μm and then formed and rolled to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com