Preparation method of graphene sheet

A graphene flake and graphite technology, applied in the field of graphene flake preparation, can solve problems such as difficulty in obtaining graphene materials, low yield, detachment of graphite fragments and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Electrolyte configuration

[0027] In the glove box, a certain amount of hexafluorophosphoric acid (LiPF 6 ) into the propylene carbonate (PC) solution, shake well until the lithium salt is completely dissolved, and the concentration is 1mol / LLiPF 6 / PC electrolyte.

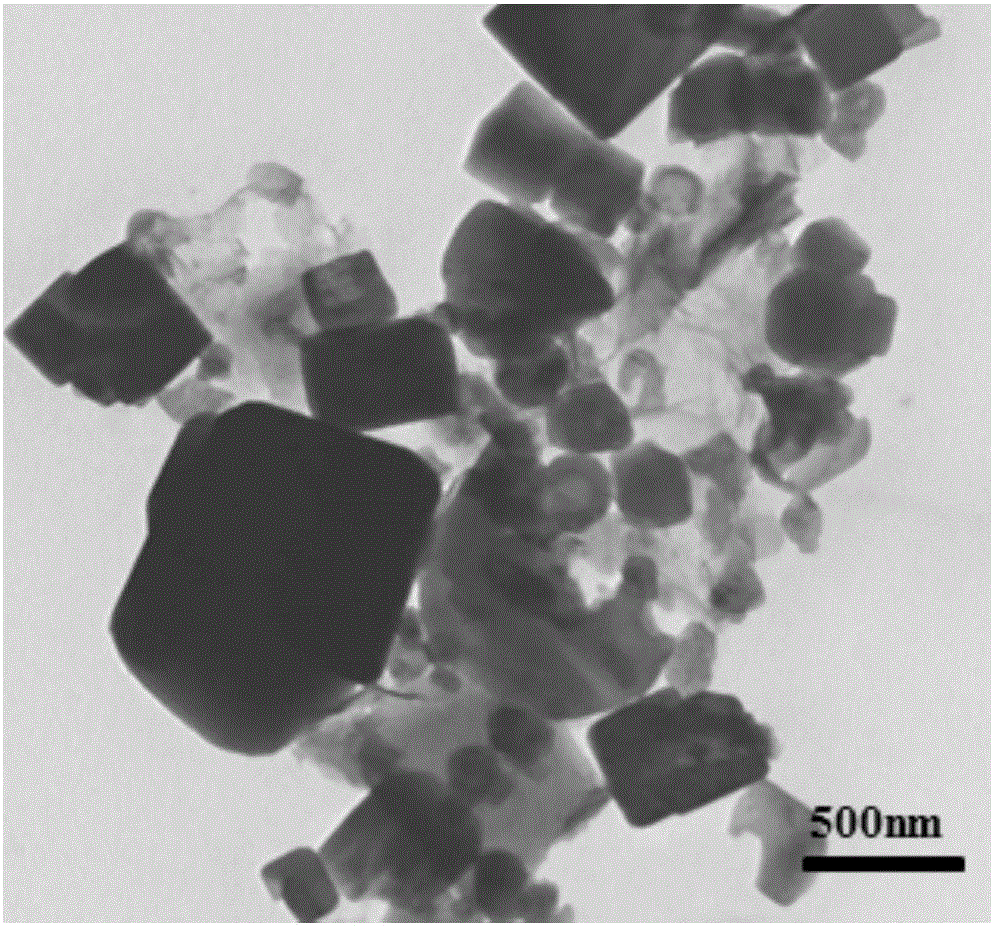

[0028] 2) Evenly disperse 2g of graphite in the reaction vessel, and drop a certain amount of 1mol / LLiPF under the protective atmosphere of argon 6 / PC electrolyte, add a certain amount of metal lithium flakes into it and stir, and after a period of reaction, expanded graphite can be obtained, such as figure 1 , figure 2 Shown are the optical micrographs of expanded graphite reacted for 2h and 4h respectively. Disperse the exfoliated expanded graphite in an alcohol solution and separate to obtain graphene flakes, such as image 3 , Figure 4 Shown are TEM pictures of graphene flakes reacted for 2h and 4h, respectively.

Embodiment 2

[0030] Repeat Example 1, the difference is that step 1) electrolyte is 0.5mol / LLiI / PC-DMC (1:1, wt), step 2) graphite and binder polyvinylidene fluoride (PVDF) are mixed by mass Mix and add appropriate amount of N-methylpyrrolidone (NMP) at a ratio of 92:8 to adjust it into a uniform slurry with certain fluidity. Coat the slurry on the pre-cleaned substrate (choose the thickness according to the need), and place it in a constant temperature oven at 60°C for 4-5h, and then transfer it to a vacuum oven at 60°C to dry for 2h, in order to completely volatilize NMP . The copper foil coated with the active material was wrapped with sulfuric acid paper (to prevent contamination), compacted with a roller press, and then dried in a vacuum oven at 60 °C for 2 h.

Embodiment 3

[0032] Repeat Example 1, the difference is that the electrolyte used in step 1) is 1.2mol / LLiTFSI / DMSO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com