Method for dyeing cotton and viscose-polyester fabrics by combining overflow dyeing and continuous dyeing

A technology for overflow dyeing and viscose polyester fabrics, applied in the dyeing and cotton fields of viscose polyester fabrics, can solve the problems of low efficiency, weight reduction, low dyeing efficiency, etc., to achieve high dyeing efficiency, small weight loss, The effect of high soaping fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

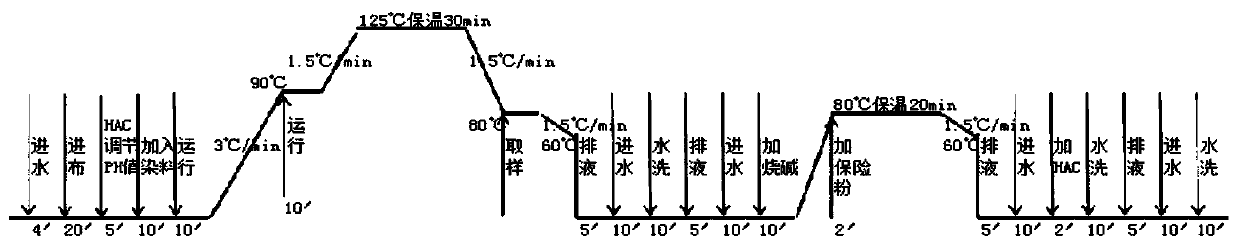

Image

Examples

Embodiment 1

[0033] Example 1. The dyeing method that overflow dyeing of cotton, viscose fabric and long car dyeing combines, comprises the following steps,

[0034] A. Turn over the cotton, viscose and polyester gray cloth to obtain product A;

[0035] B. After pretreatment of product A with alkali oxygen, cold stack at normal temperature for 24 hours to obtain product B;

[0036] The formula of the alkali-oxygen pretreatment agent is: caustic soda 10g / L, hydrogen peroxide 5g / L, refining agent 5g / L, degreasing agent 5g / L, stabilizer 5g / L, chelating agent 3g / L;

[0037] C. Debleach product B in a tight test (i.e. use a tight type debleaching agent to steam product B for 3 minutes at 98°C, wash with water, and drop the cloth.) to obtain product C;

[0038] The formulation of the tight bleaching agent is hydrogen peroxide 5g / L, refining agent 3g / L, degreaser 3g / L, stabilizer 5g / L, chelating agent 3g / L;

[0039] D. Singeing product C to obtain product D;

[0040] E. Pre-design product D t...

Embodiment 2

[0057] Example 2. The dyeing method that overflow dyeing of cotton, viscose fabric and long car dyeing combines, comprises the following steps,

[0058] A. Turn over the cotton, viscose and polyester gray cloth to obtain product A;

[0059] B. After pretreatment of product A with alkali oxygen, cold stack at normal temperature for 16 hours to obtain product B;

[0060] The formula of the alkali-oxygen pretreatment agent is: caustic soda 5g / L, hydrogen peroxide 3g / L, refining agent 3g / L, degreaser 3g / L, stabilizer 3g / L, chelating agent 1g / L;

[0061] C. Debleach product B in a tight manner (i.e. use a tight debleaching agent to steam product B for 2 minutes at 90°C, wash with water, and drop the cloth.) to obtain product C;

[0062] The formulation of the tight reagent is hydrogen peroxide 3g / L, refining agent 1g / L, degreasing agent 1g / L, stabilizer 3g / L, chelating agent 1g / L;

[0063] D. Singeing product C to obtain product D;

[0064] E. Pre-design product D to get produc...

Embodiment 3

[0080] Example 3. The dyeing method that overflow dyeing of cotton, viscose fabric and long car dyeing combines, comprises the following steps,

[0081] A. Turn over the cotton, viscose and polyester gray cloth to obtain product A;

[0082] B. After pretreatment of product A with alkali oxygen, cold stack at normal temperature for 32 hours to obtain product B;

[0083] The formula of the alkali-oxygen pretreatment agent is: caustic soda 15g / L, hydrogen peroxide 8g / L, refining agent 8g / L, degreasing agent 8g / L, stabilizer 8g / L, chelating agent 5g / L;

[0084] C. Debleach product B in a tight manner (that is, use a tight debleaching agent to steam product B for 5 minutes at 105°C, wash with water, and drop the cloth.) to obtain product C;

[0085] The formula of the tight type bleaching agent is hydrogen peroxide 8g / L, refining agent 5g / L, degreasing agent 5g / L, stabilizer 8g / L, chelating agent 5g / L;

[0086] D. Singeing product C to obtain product D;

[0087] E. Pre-design p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com