Graphene reinforced conductive PC/PBT alloy for electronic carrier tape

A technology of graphene and graphene nanosheets, which is applied in the field of engineering plastic alloys and can solve the problems of large interaction force, difficult dispersion, and agglomeration of nanosheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

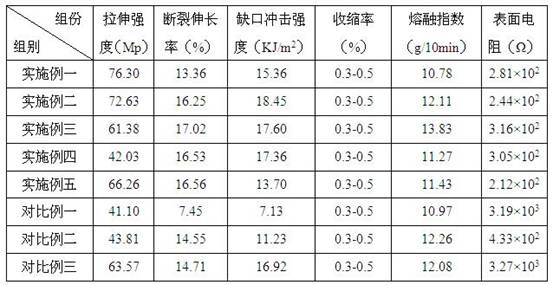

Examples

preparation example Construction

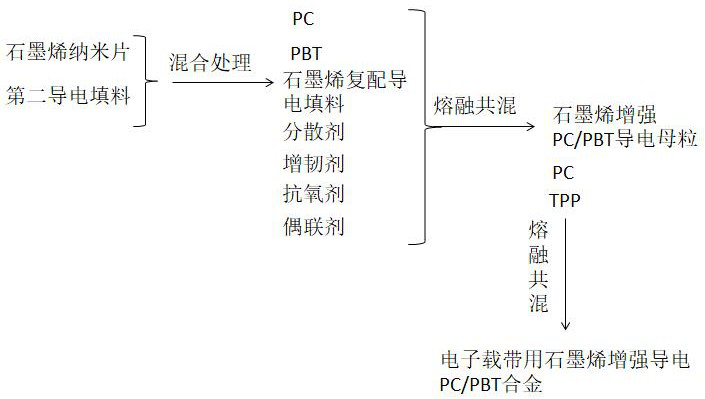

[0027] Such as figure 1 As shown, the present invention also provides a preparation method for graphene-enhanced conductive PC / PBT alloy special materials for electronic carrier tapes, comprising the following steps: (1) Preparation of graphene compounded conductive fillers: graphene nanosheets, second The conductive filler is added to the mixing equipment for mixing, the mixing temperature is 20~100°C, and the mixing time is 1~30min to obtain the compound conductive filler: (2) Preparation of graphene-enhanced conductive masterbatch: take PC and PBT as the matrix, add the above compound conductive filler Fillers, dispersants, tougheners, antioxidants, catalysts, coupling agents, blending and granulation of the prepared raw materials through melt blending technology, the melt blending temperature is set at 195~290°C, and then PC / PBT conductive masterbatch; (3) Preparation of graphene-enhanced conductive alloy: mix PC / PBT conductive masterbatch, a certain proportion of PC, and...

Embodiment 1

[0031] A preparation method of PC / PBT alloy conductive special material for electronic carrier tape, comprising the following steps:

[0032]First, add 5 parts of graphene and the second conductive filler (2 parts of arrayed carbon nanotubes, 1 part of carbon black) into a high-speed mixer and mix them at 50°C. After mixing for 30 minutes, a graphene composite conductive filler is obtained;

[0033] The second step is to use 55.4 parts of PC and 20 parts of PBT as the main raw materials, add 1.5 parts of mineral oil and 0.2 parts of organic chromium coupling agent into the high-speed mixer and mix for 1 minute, then add the above-mentioned graphene compound conductive filler and mix again for 2 minutes. After the compound conductive filler is uniformly coated on PC and PBT, add 0.2 parts of lauryl thiodipropionate, 1.5 parts of polyester wax, 3 parts of ethylene-methyl acrylate copolymer, 0.1 parts of Sb2O3 and then fully Mix for 3 minutes, then add to a twin-screw extruder fo...

Embodiment 2

[0036] A preparation method of PC / PBT alloy conductive special material for electronic carrier tape, comprising the following steps:

[0037] First, add 5 parts of graphene and the second conductive filler (2 parts of arrayed carbon nanotubes, 1 part of carbon black) into a high-speed mixer and mix them at 50°C. After mixing for 30 minutes, a graphene composite conductive filler is obtained;

[0038] In the second step, 35.4 parts of PC and 30 parts of PBT are used as the main raw materials, 1.5 parts of mineral oil and 0.2 parts of organosilane coupling agent are put into the high-speed mixer and mixed for 1 minute, then the above-mentioned graphene composite conductive filler is added and mixed for 2 minutes again, and the Coat the conductive filler evenly on PC and PBT, then add 0.2 parts of octadecyl thiodipropionate, 1.5 parts of polyester wax, 3 parts of MBS-g-GMA, 0.1 parts of Sb2O3 and mix thoroughly for 3 minutes again. Then add a twin-screw extruder for melt blending...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com