Self-repairing environmentally-friendly rubber material and preparation method thereof

An environmentally friendly rubber and self-repairing technology, applied in the field of self-repairing rubber, can solve the problems of no repairing effect, reduced self-repairing performance, and reduced service life of rubber materials, so as to promote uniform and stable vulcanization, raw materials are environmentally friendly, low-toxic, and good The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

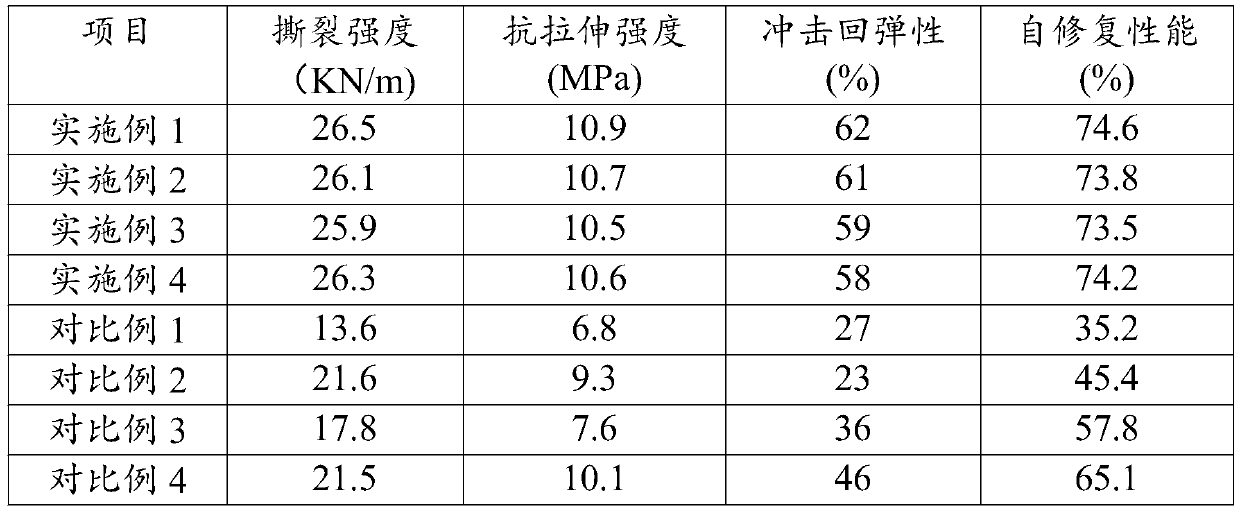

Examples

Embodiment 1

[0033] This embodiment provides a self-healing environment-friendly rubber material, which includes the following ingredients in parts by weight: 92 parts of butyl rubber matrix, 26 parts of self-healing filler, 20 parts of toughening and tensile-resistant filler, and 9 parts of vulcanization aid dispersion.

[0034] The vulcanization aid dispersion is composed of the following ingredients in parts by weight: 1.6 parts of zinc oxide, 5.2 parts of bentonite, 0.4 parts of sodium carboxymethylcellulose, 0.9 parts of accelerator TMTD, and 2.3 parts of expanded graphite.

[0035] Wherein the preparation method of self-healing filler comprises the following steps:

[0036] 1) Mix polyether polyol 330N and diamino-terminated linear polydimethylsiloxane uniformly at a mass ratio of 1:1, and then vacuum defoam at 106°C to obtain mixed liquid a; among them, polyether polyol 330N The hydroxyl value is 55-58mg KOH / g, the acid value is ≤0.15mg KOH / g, and the water content is ≤0.1%. The vis...

Embodiment 2

[0047] This embodiment provides a self-healing environment-friendly rubber material, which includes the following ingredients in parts by weight: 95 parts of butyl rubber matrix, 27 parts of self-healing filler, 23 parts of toughening and anti-stretching filler, and 10 parts of vulcanization aid dispersion.

[0048] The vulcanization aid dispersion is composed of the following ingredients in parts by weight: 2.2 parts of zinc oxide, 5.6 parts of bentonite, 0.6 parts of sodium carboxymethylcellulose, 1.1 parts of accelerator TMTD, and 2.1 parts of expanded graphite.

[0049] Wherein the preparation method of self-healing filler comprises the following steps:

[0050] 1) Mix polyether polyol 330N and diamino-terminated linear polydimethylsiloxane evenly according to the mass ratio of 1:0.96, and then vacuum defoam at 107°C to obtain mixed liquid a; among them, polyether polyol 330N The hydroxyl value is 55-58mg KOH / g, the acid value is ≤0.15mg KOH / g, and the water content is ≤0....

Embodiment 3

[0061] This embodiment provides a self-healing environment-friendly rubber material, including the following ingredients in parts by weight: 92 parts of butyl rubber matrix, 25 parts of self-healing filler, 24 parts of toughening and anti-stretching filler, and 10 parts of vulcanization aid dispersion.

[0062] The vulcanization aid dispersion is composed of the following ingredients in parts by weight: 2.6 parts of zinc oxide, 5.6 parts of bentonite, 0.7 parts of sodium carboxymethylcellulose, 1.1 parts of accelerator TMTD, and 2.3 parts of expanded graphite.

[0063] Wherein the preparation method of self-healing filler comprises the following steps:

[0064] 1) Mix polyether polyol 330N and diamino-terminated linear polydimethylsiloxane evenly according to the mass ratio of 1:1.06, and then vacuum defoam at 106°C to obtain mixed liquid a; among them, polyether polyol 330N The hydroxyl value is 55-58mg KOH / g, the acid value is ≤0.15mg KOH / g, and the water content is ≤0.1%. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com