Plastic master batch and preparation method and application thereof

A plastic masterbatch and antioxidant technology, applied in the field of plastic masterbatch and its preparation, can solve the problems of large density difference of polymer matrix, high thermal conductivity, high oxygen resistance performance, product safety risk, etc., and achieve melt strength And the effect of improving the gel quality and good oxygen barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

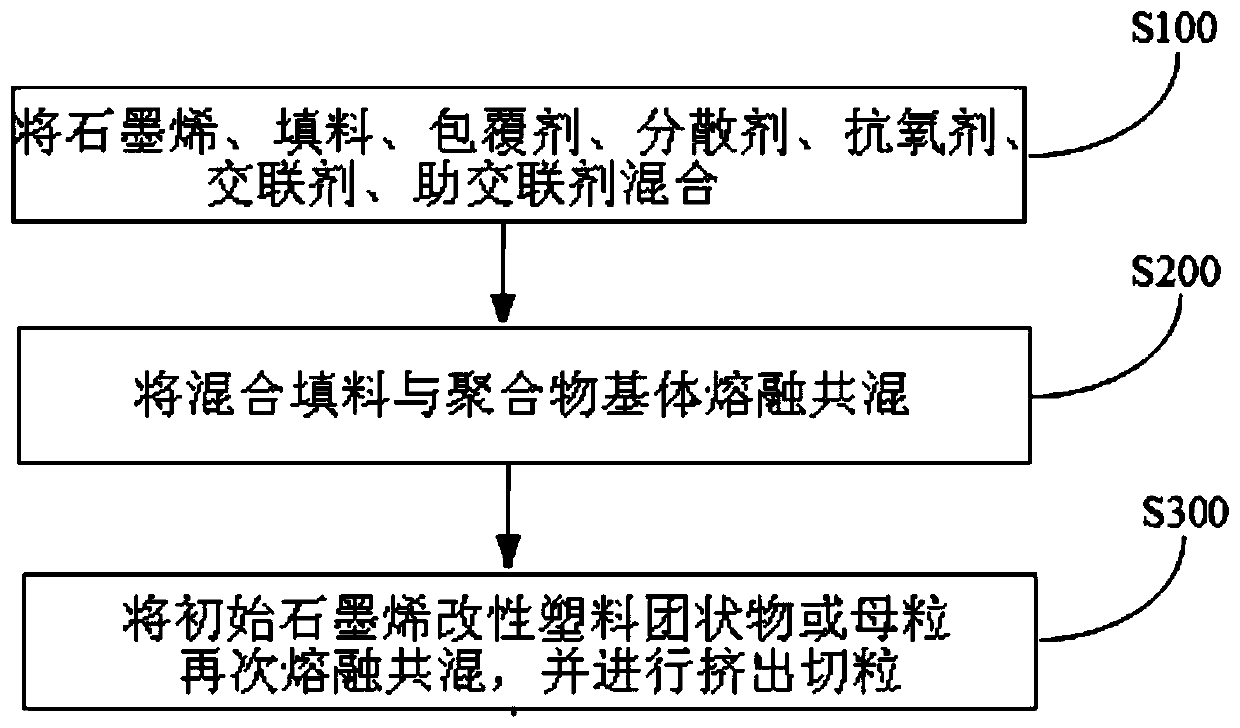

[0052] According to the method for preparing plastic master batches according to the embodiments of the present invention, at a first predetermined temperature, by mixing graphene, fillers, coating agents, dispersants, antioxidants, crosslinking agents, and auxiliary crosslinking agents for the first predetermined temperature time, and then at a second predetermined temperature, melt-blending the mixed filler with the polymer matrix for a second predetermined time, and finally at a third predetermined temperature, the initial graphene-modified plastic mass or masterbatch Melt-blending again for a third predetermined time, and extruding and pelletizing to obtain plastic masterbatches, that is, graphene and other fillers and polymer matrix are pre-dispersed-melt-blended-secondary melt-blended granulated three The step-by-step route enables graphene and other fillers to achieve sufficient exfoliation and uniform dispersion in the polymer matrix, thereby obtaining a plastic masterb...

Embodiment 1

[0063] The method for preparing plastic masterbatch, comprises the following steps:

[0064] (1) 20 parts of graphene prepared by mechanical exfoliation (radial size is 2-5 μm, thickness is 2-4 nm), 5 parts of micropowder graphite, 10 parts of styrene-ethylene-butylene-styrene block copolymer (SEBS), 5 parts of vinyl bis stearamide (EBS), 0.5 parts of antioxidant 1010, 0.1 part of dicumyl peroxide (DCP), 1 part of triallyl isocyanurate (TAIC) Add it into a high-speed mixer, mix at 60°C for 20 minutes, and rotate at 500 rpm to obtain a mixed filler that has been pre-dispersed and coated;

[0065] (2) The mixed filler obtained above and 58.4 parts of random copolymerized polypropylene resin (PPR) particles were added to an overturning internal mixer, and mixed for 20 minutes at 200 ° C to obtain an initial graphene-modified plastic mass;

[0066] (3) The initial graphene-modified plastic obtained above was granulated through a twin-screw extruder, the extrusion temperature was ...

Embodiment 2

[0068] The method for preparing plastic masterbatch, comprises the following steps:

[0069] (1) 40 parts of graphene prepared by mechanical exfoliation (radial size is 2-5 μm, thickness is 2-4 nm), 10 parts of micropowder graphite, 20 parts of styrene-ethylene-butylene-styrene block copolymer (SEBS), 10 parts of vinyl bis stearamide (EBS), 0.3 parts of antioxidant 1010, 0.2 parts of dicumyl peroxide (DCP), 2 parts of triallyl isocyanurate (TAIC) Add it into a high-speed mixer, mix at 60°C for 20 minutes, and rotate at 500 rpm to obtain a mixed filler that has been pre-dispersed and coated;

[0070] (2) The mixed filler obtained above and 17.5 parts of random copolymerized polypropylene resin (PPR) particles were added to an overturning internal mixer, and mixed for 20 minutes at 200 ° C to obtain an initial graphene-modified plastic mass;

[0071] (3) The initial graphene-modified plastic mass obtained above was granulated through a twin-screw extruder at an extrusion temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com