Tin-soldering resistant polybutylece terephthalate (PBT) engineering plastic and method for preparing same

A technology for engineering plastics and soldering, which is applied in the field of solder-resistant engineering plastic PBT and its preparation, can solve the problems of inability to meet the use environment, and achieve the effects of meeting the requirements of solder resistance, good compatibility, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

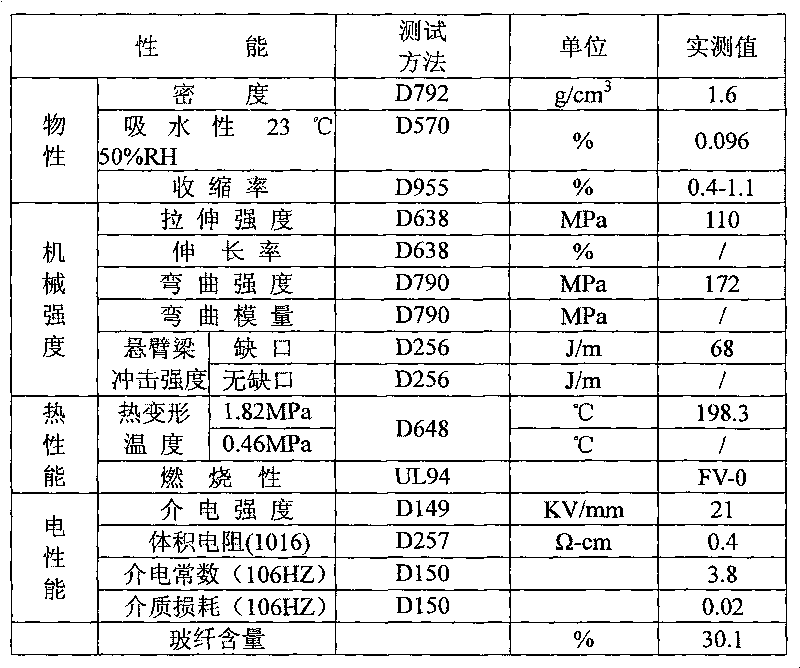

[0014] (1) Product formula

[0015]

product name

Add ratio (weight percent

Compare)

PBT

40.4%

Decabromodiphenylethane

13%

[0016]

product name

Add ratio (weight percent

Compare)

5%

PTW (ethylene-butyl acrylate-glycidyl

ester terpolymer)

4%

Antiaging agent 1076 (β-(3,5-di-tert-butyl

-4-Hydroxyphenyl) octadecyl propionate)

0.2%

Anti-aging agent 626 (pentaerythritol diphosphite

Ester bis-(2,4-di-tert-butylphenyl))

0.4%

Short glass fiber (length 2-4mm)

30%

TN3500 (modified polytetrafluoroethylene)

5%

A-C 540 (polyethylene wax)

2%

Sum

100%

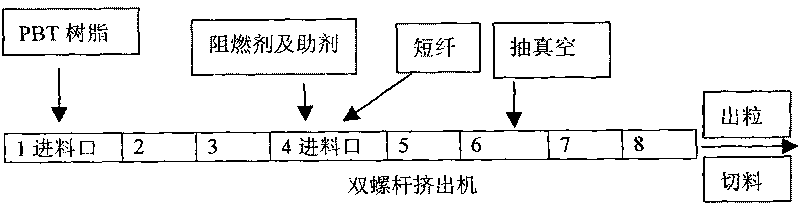

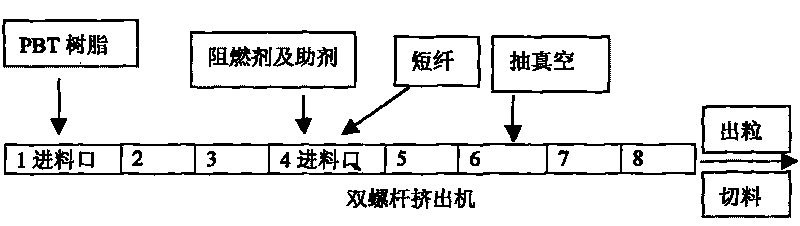

[0017] (2) Production process

[0018] Polybutylene terephthalate enters from the first barrel of the twin-screw extruder after drying, flame retardants (decabromodiphenylethane and antimony trioxide),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com