Terylene reduction cleaning agent and preparation method thereof

A technology of cleaning agent and polyester, which is applied in the field of polyester reduction cleaning agent and its preparation, can solve the problems of respiratory occupational diseases, exceeding the spontaneous combustion temperature, heat reaching of powdered sodium dithionite, etc., to improve stability and reliability, and improve stripping ability , Improve the effect of restoring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

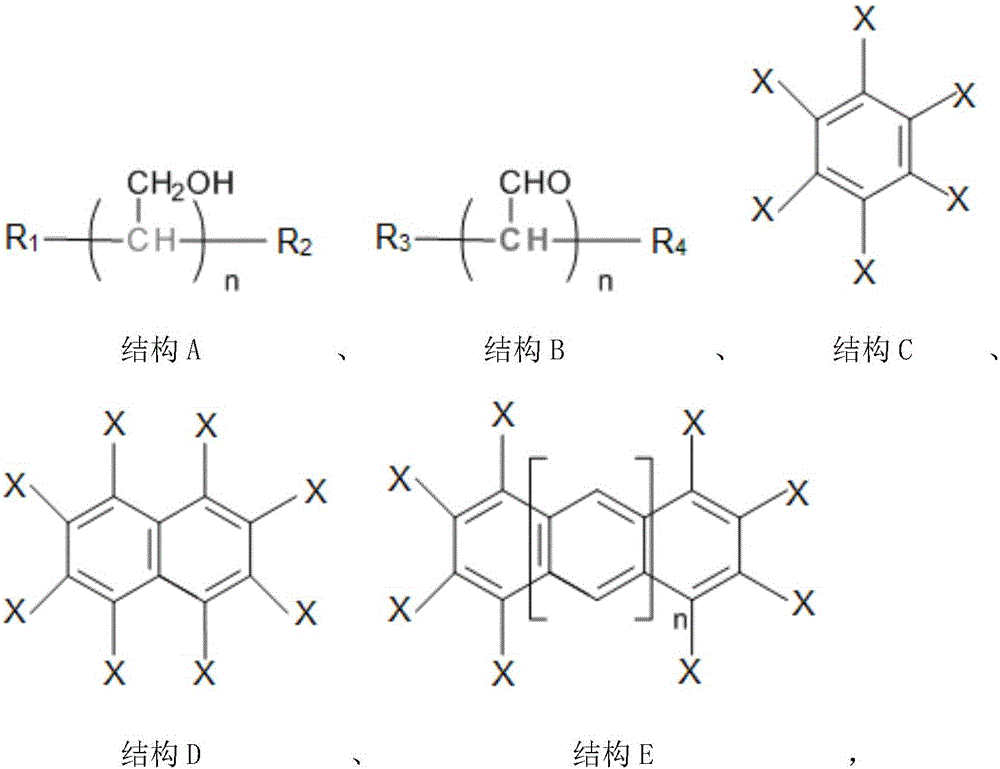

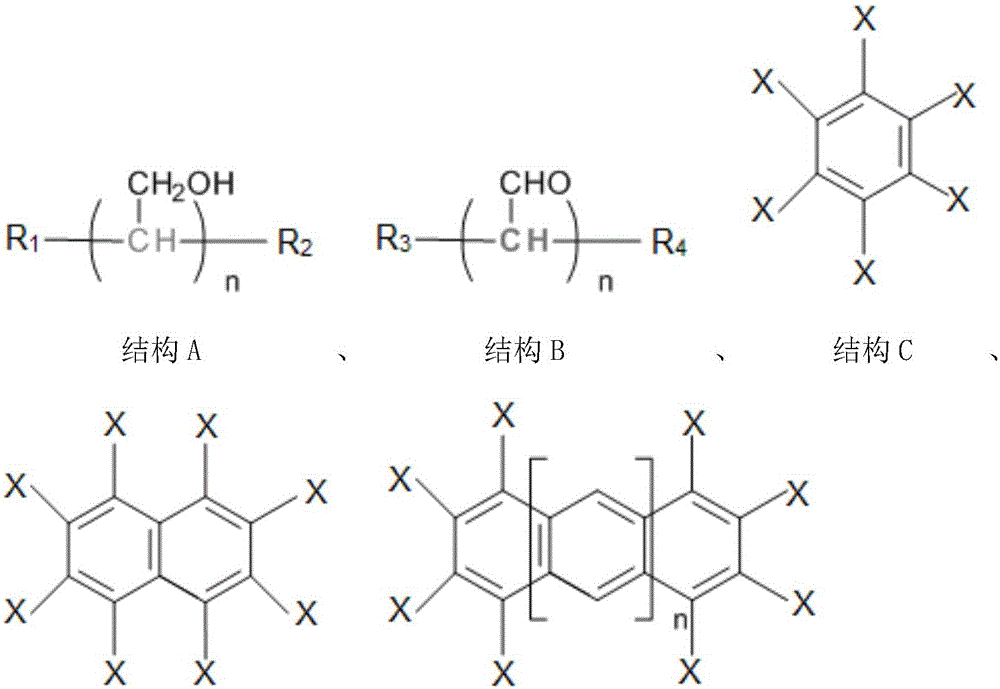

[0052] The reducing cleaning agent for polyester of the present invention comprises a mixture of deionized water, main reducing components, sulfite, alkylbenzene sulfonate, alkyl alcohol polyoxyethylene ether, phosphate and sodium acetate. Among them, the main reducing component is isomeric polyol, and its molecular structure is:

[0053]

[0054] In the above molecular structure, n is 1, and R1 and R2 are hydrogen and an alkyl group with 1 carbon atom respectively. The molar ratio of main reducing agent and secondary reducing agent is 4:1, and the pH value is controlled at 5. The above components are calculated in parts by mass: 84 parts of deionized water, 8 parts of isomeric polyol, 2 parts of sulfite, 3 parts of alkylbenzene sulfonate, 2 parts of alkyl alcohol polyoxyethylene ether, phosphoric acid 0.5 parts of salt, 0.5 parts of sodium acetate.

[0055] The steps of the preparation method of the reduction cleaning agent for above-mentioned polyester are as follows: ...

Embodiment 2

[0061] The reduction cleaning agent for polyester of the present invention comprises deionized water, main reducing components, sulfite, sodium thiosulfate, alkali sulfide, sodium hydrosulfide, ferrous chloride, zincous chloride, sodium borohydride, borohydride Mixture of potassium, alkylbenzene sulfonates, alkyl sulfates, polyoxyethylene ether sulfates, polyoxyethylene ether phosphates, alkyl alcohol ethoxylates, fatty amine ethoxylates, phosphates and ethanolamines. Among them, the main reducing component is a mixture of isomeric polyols and isomeric polyaldehydes, and its molecular structure is:

[0062]

[0063] In the above molecular structure, n is 100, R3 and R4 are straight chain alkyl and benzene ring with 6 carbon atoms respectively, and X is CH 2 Oh. The molar ratio of the main reducing agent and the secondary reducing agent is 11:1, and the pH value is controlled at 9. The above components are calculated in parts by mass: 35 parts of deionized water, 20 parts ...

Embodiment 3

[0070] The reduction cleaning agent for polyester of the present invention comprises deionized water, main reducing components, sodium thiosulfate, alkali sulfide, sodium hydrosulfide, alkyl sulfate, polyoxyethylene ether sulfate, polyoxyethylene ether phosphate, fat Mixture of amine ethoxylates, phosphate and sodium carbonate. Among them, the main reducing component is isomeric polyaldehyde, and its molecular structure is:

[0071]

[0072]

[0073] X in the above molecular structure is CH 2 O. The molar ratio of main reducing agent and secondary reducing agent is 4:1, and the pH value is controlled at 6. The above components are calculated in parts by mass: 63 parts of deionized water, 20 parts of isomeric polyaldehyde, 1 part of sodium thiosulfate, 1 part of alkali sulfide, 3 parts of sodium hydrosulfide, 3 parts of alkyl sulfate, poly 2 parts of oxyethylene ether sulfate, 3 parts of polyoxyethylene ether phosphate, 2 parts of fatty amine polyoxyethylene ether, 1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com