Coptis chinensis stem and leaf batched separation equipment of Chinese medicinal herb processing

A separation equipment and stem-leaf separation technology, applied in solid separation, metal processing, mechanical equipment, etc., can solve the problems of increased procedures, high labor costs, and low separation efficiency, and achieve the effect of reducing work procedures and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

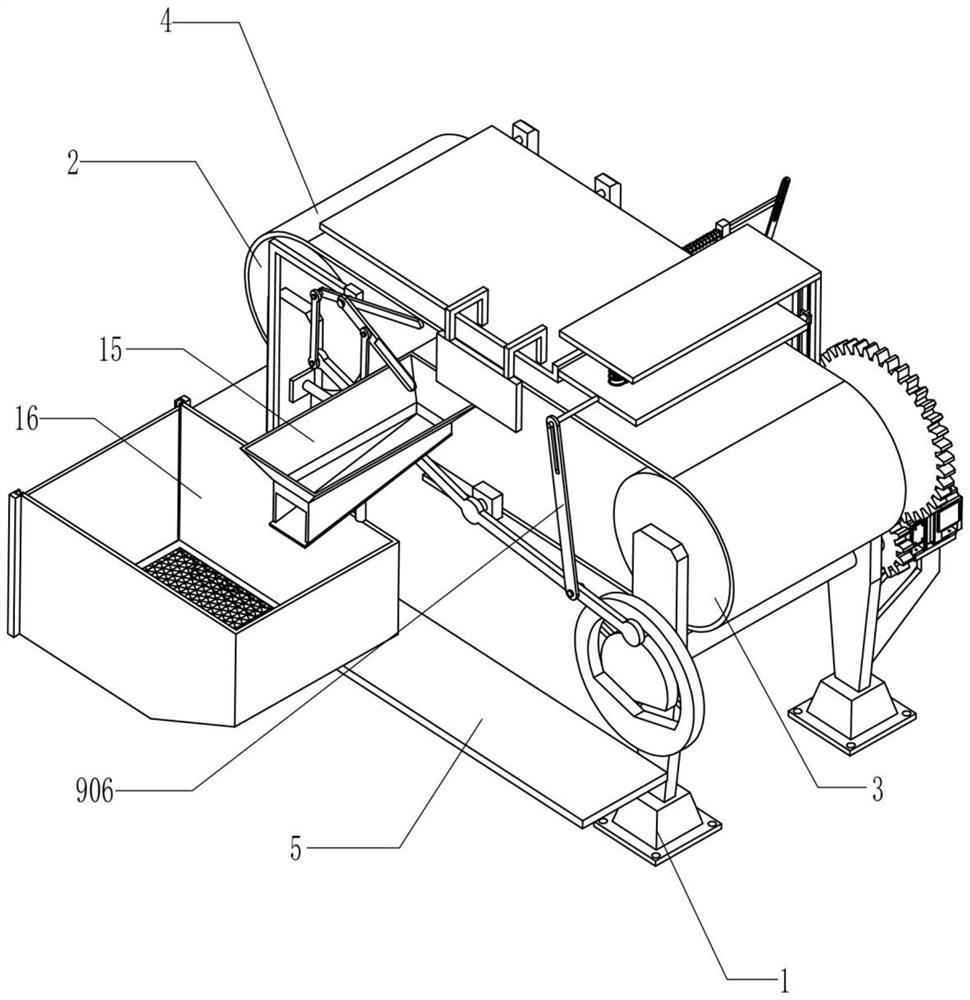

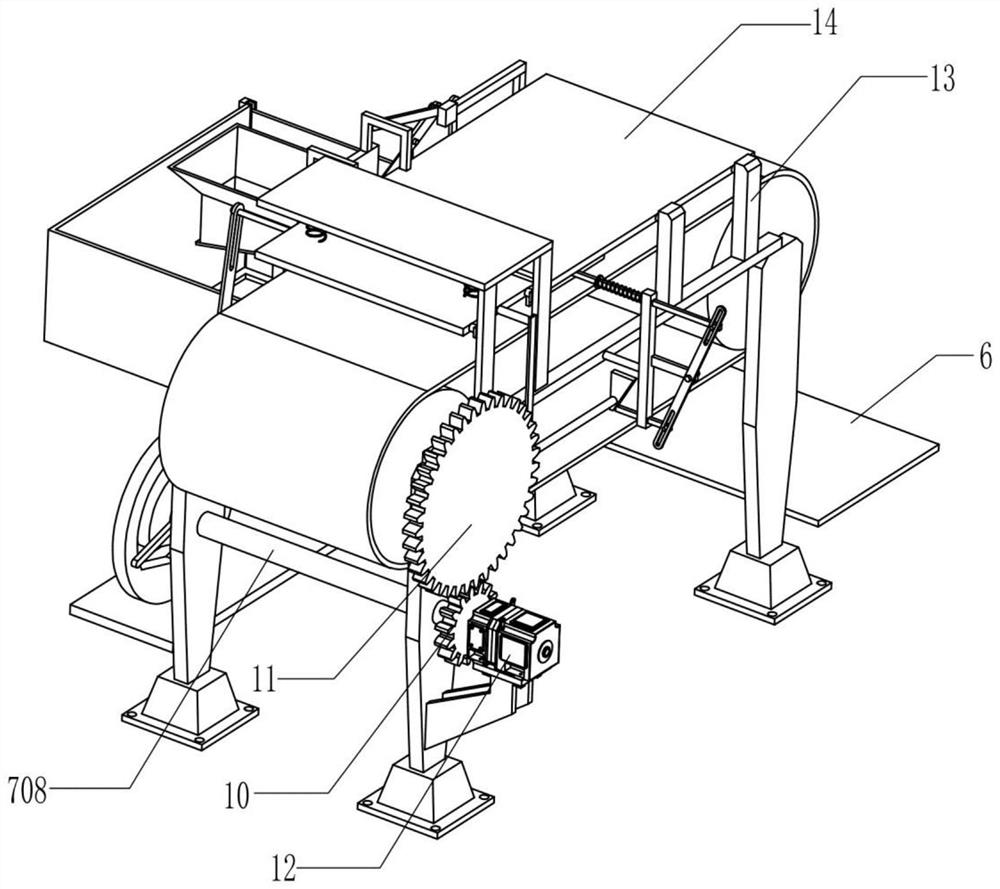

[0022] A batch separation equipment for Coptis chinensis stems and leaves for Chinese medicine processing, such as Figure 1-6 As shown, it includes a base 1, a first drive roller 2, a second drive roller 3, a conveyor belt 4, a long plate 5, a placement plate 6, a Coptis chinensis stem and leaf separation device 7, a first support rod 8, a Coptis chinensis compacting device 9, Small-diameter gear 10, large-diameter gear 11, servo motor 12, second support rod 13, top pressing plate 14, discharge hopper 15, receiving hopper 16, second slide rail 17 and slide plate 18, the first transmission roller 2 and the second The drive roller 3 is mounted on the base 1 in a rotatable manner, and a conveyor belt 4 is connected between the first drive roller 2 and the second drive roller 3 for transporting Coptidis rhizome, and the long board 5 is fixedly mounted on the base 1. The placement plate 6 is fixedly installed on the base 1 and is close to the long board 5, the placement board 6 is...

Embodiment 2

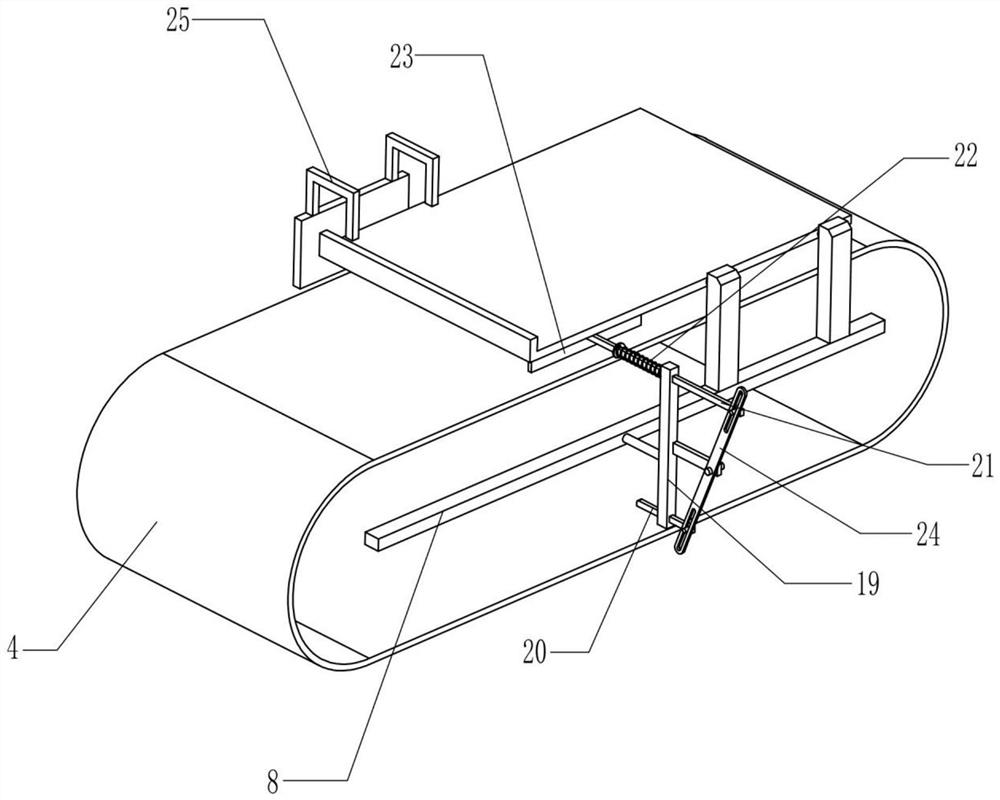

[0028] On the basis of Embodiment 1, such as image 3 and Figure 5 As shown, it also includes a guide frame 19, a first guide rod 20, a second guide rod 21, a second compression spring 22, a push plate 23, a second groove rod 24, a limiting plate 25, a connecting rod 26 and a wedge plate 27 , the guide frame 19 is fixedly installed on the first support rod 8 and the upper and lower ends of the guide frame 19 are provided with guide holes, the guide frame 19 is located between the second support rod 13 and the first slide rail 901, so The first guide rod 20 is slidably installed in the guide hole at the lower end of the guide frame 19, and the second guide rod 21 is slidably installed in the guide hole at the upper end of the guide frame 19. A second compression spring 22 is installed between one side of the guide frame 19 and the second guide rod 21 passes through the second compression spring 22, and one end of the second guide rod 21 is fixedly equipped with a push plate 2...

Embodiment 3

[0031] On the basis of Example 2, such as Figure 6 As shown, a filter screen 28 is also included, and a filter screen 28 is installed in the receiving hopper 16 .

[0032] Before carrying out stem-leaf separation operation to Coptidis Rhizome, the staff also needs to place a trash can under the receiving hopper 16 . After the first scissors 704 and the second scissors 705 separate the rhizomes and branches and leaves of Coptis chinensis, some branches and leaves of Coptis chinensis and cut debris will fall into the receiving hopper 16 together with the rhizomes of Coptis chinensis. Be that the rhizome is isolated from these impurities, the rhizome of Coptidis Rhizome is allowed to stay on the filter screen 28, and these impurities are allowed to fall into the trash can. When the Coptis rhizome in the receiving hopper 16 accumulates to a certain amount, the staff can promote the slide plate 18 to move upwards, and then the Coptidis rhizome in the receiving hopper 16 is taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com